Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

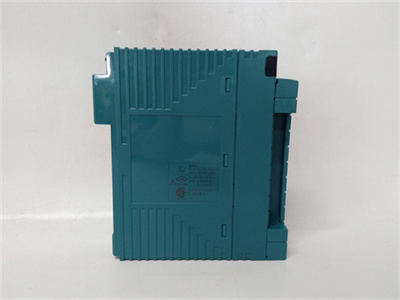

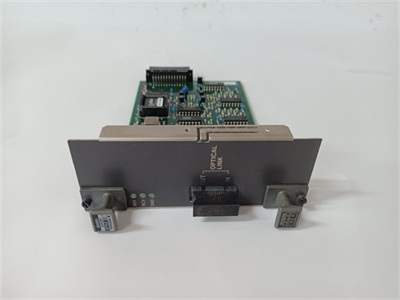

Yokogawa ANR10D-420/ATDOC/NDEL ER Bus Unit

Manufacturer:Yokogawa

Product Number:ANR10D-420/ATDOC/NDEL

Product Type:ER Bus Unit

Origin:Japan

Dimensions:482.6 × 221.5 × 205 mm

Weight:10 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANR10D-420/ATDOC/NDEL ER Bus Unit is an integral component of Yokogawa’s industrial automation and safety systems, particularly tailored for high-performance and reliable communication in demanding environments. It forms part of the ProSafe-RS (SIS – Safety Instrumented System) architecture, facilitating robust and secure communication between I/O units and controllers via the ER Bus (Extension Redundant Bus).

Designed with flexibility and system integrity in mind, this ER Bus Unit ensures that safety-critical applications such as Emergency Shutdown Systems (ESD), Burner Management Systems (BMS), and Fire & Gas Systems (FGS) maintain uninterrupted data exchange. Its configuration supports redundancy, fault tolerance, and easy scalability, all essential for critical plant operations in industries such as oil and gas, petrochemical, and power generation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ANR10D-420/ATDOC/NDEL |

| Product Type | ER Bus Interface Unit (Redundant) |

| System Compatibility | Yokogawa ProSafe-RS Series |

| Power Supply | Supplied via baseplate from system |

| Input Voltage | 24 V DC nominal |

| Current Consumption | Approx. 150 mA |

| Communication Interface | Dual ER Bus lines (redundant communication path) |

| Max Distance (ER Bus) | Up to 100 meters per segment |

| Redundancy Support | Yes (fully redundant I/O communication capability) |

| Operating Temperature | 0 to +55°C (32 to 131°F) |

| Storage Temperature | -20 to +70°C (-4 to 158°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Ingress Protection | IP30 (when installed in a cabinet) |

| Mounting Method | DIN rail mountable |

| Dimensions (W x H x D) | 482.6 × 221.5 × 205 mm |

| Weight | 10 kg |

| Certifications | SIL3 (IEC 61508), CE, ATEX, FM, CSA |

| Firmware Upgradeable | Yes, via system engineering tool |

| Diagnostics | Built-in self-diagnostics, LED indicators for status and fault |

Applications

The ANR10D-420/ATDOC/NDEL ER Bus Unit is designed for mission-critical safety applications across various process industries. Some key application areas include:

Emergency Shutdown Systems (ESD)

Ensures that processes are safely shut down during abnormal situations or equipment failures.

Burner Management Systems (BMS)

Handles safe start-up, operation, and shutdown of industrial burners to prevent explosions or fire.

Fire and Gas Detection Systems (FGS)

Integrates with sensors and alarms to ensure immediate response in case of fire or gas leaks.

Compressor and Turbine Control

Used in conjunction with safety controllers to protect rotating machinery.

Offshore Oil Platforms

Functions as part of redundant communication systems to ensure uninterrupted safety logic processing.

Petrochemical Processing Plants

Maintains secure and fail-safe communication in facilities with hazardous and flammable materials.

Product Advantages

Redundant Communication

Offers dual-channel ER Bus support to ensure no single point of failure in communication.

Compact Form Factor

With its narrow 30 mm width, the unit is ideal for space-constrained installations.

Robust Safety Certification

Certified to SIL3 per IEC 61508, ensuring suitability for the most critical safety applications.

Built-in Diagnostics

Real-time self-checking and LED indicators allow for rapid fault identification and troubleshooting.

Seamless Integration

Natively integrates with the ProSafe-RS system for simplified configuration and maintenance.

Wide Environmental Tolerance

Operates reliably across a broad temperature range with high humidity resistance.

Frequently Asked Questions (FAQ)

Q: What system is the ANR10D-420/ATDOC/NDEL compatible with?

A: It is designed specifically for use with Yokogawa’s ProSafe-RS Safety Instrumented System.

Q: Is this unit capable of redundant communication?

A: Yes, it supports full ER Bus redundancy to enhance system reliability.

Q: What is the maximum cable length supported by the ER Bus?

A: Up to 100 meters per segment.

Q: Does the unit require a separate power supply?

A: No, power is supplied via the system baseplate.

Q: Can this unit be mounted directly to a panel?

A: It is DIN rail mountable and designed for installation in a control cabinet.

Q: What is the operating temperature range?

A: 0 to +55°C (32 to 131°F).

Q: Is the unit firmware upgradeable?

A: Yes, firmware upgrades can be performed via the system’s engineering tools.

Q: What type of diagnostics does it support?

A: Built-in diagnostics with front-panel LED indicators for status, communication, and faults.

Q: What safety certifications does it have?

A: It meets SIL3 certification and complies with CE, ATEX, FM, and CSA standards.

Q: Can the unit be hot-swapped?

A: No, power-down is required before replacement to ensure safe operation.

Yokogawa ANR10D-420/ATDOC/NDEL ER Bus Unit

Manufacturer:Yokogawa

Product Number:ANR10D-420/ATDOC/NDEL

Product Type:ER Bus Unit

Origin:Japan

Dimensions:482.6 × 221.5 × 205 mm

Weight:10 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANR10D-420/ATDOC/NDEL ER Bus Unit is an integral component of Yokogawa’s industrial automation and safety systems, particularly tailored for high-performance and reliable communication in demanding environments. It forms part of the ProSafe-RS (SIS – Safety Instrumented System) architecture, facilitating robust and secure communication between I/O units and controllers via the ER Bus (Extension Redundant Bus).

Designed with flexibility and system integrity in mind, this ER Bus Unit ensures that safety-critical applications such as Emergency Shutdown Systems (ESD), Burner Management Systems (BMS), and Fire & Gas Systems (FGS) maintain uninterrupted data exchange. Its configuration supports redundancy, fault tolerance, and easy scalability, all essential for critical plant operations in industries such as oil and gas, petrochemical, and power generation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ANR10D-420/ATDOC/NDEL |

| Product Type | ER Bus Interface Unit (Redundant) |

| System Compatibility | Yokogawa ProSafe-RS Series |

| Power Supply | Supplied via baseplate from system |

| Input Voltage | 24 V DC nominal |

| Current Consumption | Approx. 150 mA |

| Communication Interface | Dual ER Bus lines (redundant communication path) |

| Max Distance (ER Bus) | Up to 100 meters per segment |

| Redundancy Support | Yes (fully redundant I/O communication capability) |

| Operating Temperature | 0 to +55°C (32 to 131°F) |

| Storage Temperature | -20 to +70°C (-4 to 158°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Ingress Protection | IP30 (when installed in a cabinet) |

| Mounting Method | DIN rail mountable |

| Dimensions (W x H x D) | 482.6 × 221.5 × 205 mm |

| Weight | 10 kg |

| Certifications | SIL3 (IEC 61508), CE, ATEX, FM, CSA |

| Firmware Upgradeable | Yes, via system engineering tool |

| Diagnostics | Built-in self-diagnostics, LED indicators for status and fault |

Applications

The ANR10D-420/ATDOC/NDEL ER Bus Unit is designed for mission-critical safety applications across various process industries. Some key application areas include:

Emergency Shutdown Systems (ESD)

Ensures that processes are safely shut down during abnormal situations or equipment failures.

Burner Management Systems (BMS)

Handles safe start-up, operation, and shutdown of industrial burners to prevent explosions or fire.

Fire and Gas Detection Systems (FGS)

Integrates with sensors and alarms to ensure immediate response in case of fire or gas leaks.

Compressor and Turbine Control

Used in conjunction with safety controllers to protect rotating machinery.

Offshore Oil Platforms

Functions as part of redundant communication systems to ensure uninterrupted safety logic processing.

Petrochemical Processing Plants

Maintains secure and fail-safe communication in facilities with hazardous and flammable materials.

Product Advantages

Redundant Communication

Offers dual-channel ER Bus support to ensure no single point of failure in communication.

Compact Form Factor

With its narrow 30 mm width, the unit is ideal for space-constrained installations.

Robust Safety Certification

Certified to SIL3 per IEC 61508, ensuring suitability for the most critical safety applications.

Built-in Diagnostics

Real-time self-checking and LED indicators allow for rapid fault identification and troubleshooting.

Seamless Integration

Natively integrates with the ProSafe-RS system for simplified configuration and maintenance.

Wide Environmental Tolerance

Operates reliably across a broad temperature range with high humidity resistance.

Frequently Asked Questions (FAQ)

Q: What system is the ANR10D-420/ATDOC/NDEL compatible with?

A: It is designed specifically for use with Yokogawa’s ProSafe-RS Safety Instrumented System.

Q: Is this unit capable of redundant communication?

A: Yes, it supports full ER Bus redundancy to enhance system reliability.

Q: What is the maximum cable length supported by the ER Bus?

A: Up to 100 meters per segment.

Q: Does the unit require a separate power supply?

A: No, power is supplied via the system baseplate.

Q: Can this unit be mounted directly to a panel?

A: It is DIN rail mountable and designed for installation in a control cabinet.

Q: What is the operating temperature range?

A: 0 to +55°C (32 to 131°F).

Q: Is the unit firmware upgradeable?

A: Yes, firmware upgrades can be performed via the system’s engineering tools.

Q: What type of diagnostics does it support?

A: Built-in diagnostics with front-panel LED indicators for status, communication, and faults.

Q: What safety certifications does it have?

A: It meets SIL3 certification and complies with CE, ATEX, FM, and CSA standards.

Q: Can the unit be hot-swapped?

A: No, power-down is required before replacement to ensure safe operation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...