Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

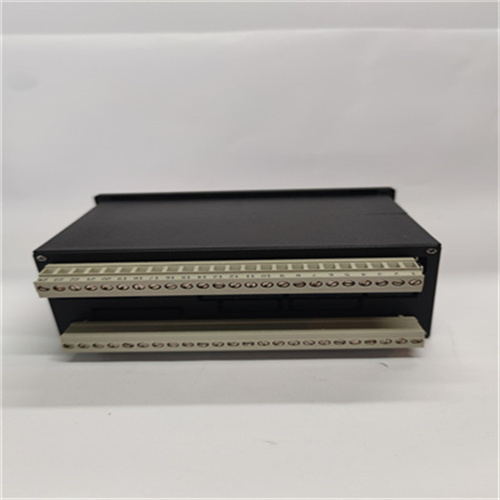

Woodward 9905-263 Digital Control Module

Manufacturer:Woodward

Product Number:9905-263

Product Type:Digital Control Module

Origin:USA

Dimensions:216 x 191 x 50 mm

Weight:1.1 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-263 Digital Control Module is a high-performance, microprocessor-based control unit designed for precise and reliable control of prime movers such as diesel and gas engines or steam and gas turbines. Developed as part of Woodward’s renowned digital control product family, the 9905-263 is engineered for applications where flexible configuration, real-time control, and long-term reliability are essential.

The module integrates digital speed governing, load sharing, and system protection features, making it suitable for both standalone and complex multi-unit control systems. It supports programmable logic, communications with remote systems, and real-time monitoring—making it a go-to choice for OEMs and industrial operators looking to modernize or streamline generator and turbine management.

Compact, rugged, and highly adaptable, the 9905-263 is designed to operate in harsh industrial environments while maintaining consistent performance. Whether it’s used in power generation, marine propulsion, oilfield operations, or industrial processing plants, this controller ensures efficient operation, stable power output, and simplified system integration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9905-263 |

| Product Type | Digital Control Module |

| Operating Voltage | 18–32 VDC |

| Power Consumption | <15 W |

| Processor Type | High-speed microprocessor |

| Control Functions | Speed control, load sharing, start/stop, protection |

| Input Signals | MPU, discrete I/Os, analog sensors |

| Output Signals | PWM, analog outputs, relay contacts |

| Communication Ports | RS-232 / RS-485 (Modbus), optional CANbus |

| Display | LED status indicators |

| Software Configuration | PC-based software interface (ToolKit or GAP) |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Humidity Tolerance | 95% RH non-condensing |

| Mounting Type | Panel mount |

| Enclosure Type | Metal, shielded, industrial |

| Dimensions (H × W × D) | 216 x 191 x 50 mm |

| Weight | 1.1 kg |

| Certifications | CE, UL, CSA (as applicable) |

Applications

Diesel and Gas Engine Control: Provides precise control for prime movers in generator sets, compressors, or pumps.

Steam and Gas Turbine Systems: Integrated control logic for speed, load, and safety functions.

Power Generation Systems: Used for automated control in standalone or parallel generator operation.

Marine and Offshore Applications: Controls propulsion engines and auxiliary generators on ships and rigs.

Industrial Automation: Provides automation logic for rotating machinery in refineries, paper mills, or mining sites.

Oil and Gas Fields: Operates engine-driven compressors or electric power systems in remote, demanding locations.

Advantages

All-in-One Digital Control: Combines governing, load sharing, start/stop logic, and monitoring in one module.

Flexible Configuration: Supports multiple I/O types and configurable parameters through software.

Robust Communication: Equipped with RS-232/RS-485 for Modbus communication; CANbus optional.

Precision Performance: Microprocessor-based control ensures stable, accurate speed and load regulation.

Wide Application Range: Suitable for turbines, engines, and gensets in industrial or marine environments.

Harsh Environment Ready: Operates in wide temperature and humidity ranges with a rugged enclosure.

Minimal Downtime: Designed for high reliability and long-term continuous operation.

Easy Integration: Compatible with legacy systems and modern digital architectures.

Reduced Footprint: Compact, panel-mounted unit reduces control cabinet space.

Global Compliance: Certified to international industrial safety and EMC standards.

Frequently Asked Questions (FAQ)

Q: What is the main use of the 9905-263 digital control module?

A: It is primarily used for controlling the speed, load, and operational logic of engines and turbines in industrial applications.

Q: Does it support remote communication?

A: Yes, it features RS-232/RS-485 serial communication and optionally CANbus for remote monitoring and control.

Q: What types of input signals can the unit process?

A: It accepts magnetic pickup (MPU), analog signals, and discrete input contacts.

Q: Can this module control generator loading and synchronization?

A: Yes, it supports load sharing and can integrate with synchronizers for multi-generator systems.

Q: What is the operating voltage range?

A: The unit operates on 18–32 VDC input, making it suitable for 24 VDC control panels.

Q: How is the unit programmed or configured?

A: Configuration is done via Woodward ToolKit or GAP software through a PC interface.

Q: Is the controller suitable for marine environments?

A: Yes, it is built with a robust enclosure and wide operating specs, making it suitable for offshore and marine use.

Q: What kind of outputs does it provide?

A: It provides PWM, analog outputs for actuators, and dry contact relays for status and alarms.

Q: Can this module operate in extreme temperatures?

A: Yes, it functions reliably from –40 °C to +70 °C.

Q: What are the dimensions and weight of the unit?

A: It measures 216 x 191 x 50 mm and weighs 1.1 kg.

Woodward 9905-263 Digital Control Module

Manufacturer:Woodward

Product Number:9905-263

Product Type:Digital Control Module

Origin:USA

Dimensions:216 x 191 x 50 mm

Weight:1.1 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-263 Digital Control Module is a high-performance, microprocessor-based control unit designed for precise and reliable control of prime movers such as diesel and gas engines or steam and gas turbines. Developed as part of Woodward’s renowned digital control product family, the 9905-263 is engineered for applications where flexible configuration, real-time control, and long-term reliability are essential.

The module integrates digital speed governing, load sharing, and system protection features, making it suitable for both standalone and complex multi-unit control systems. It supports programmable logic, communications with remote systems, and real-time monitoring—making it a go-to choice for OEMs and industrial operators looking to modernize or streamline generator and turbine management.

Compact, rugged, and highly adaptable, the 9905-263 is designed to operate in harsh industrial environments while maintaining consistent performance. Whether it’s used in power generation, marine propulsion, oilfield operations, or industrial processing plants, this controller ensures efficient operation, stable power output, and simplified system integration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9905-263 |

| Product Type | Digital Control Module |

| Operating Voltage | 18–32 VDC |

| Power Consumption | <15 W |

| Processor Type | High-speed microprocessor |

| Control Functions | Speed control, load sharing, start/stop, protection |

| Input Signals | MPU, discrete I/Os, analog sensors |

| Output Signals | PWM, analog outputs, relay contacts |

| Communication Ports | RS-232 / RS-485 (Modbus), optional CANbus |

| Display | LED status indicators |

| Software Configuration | PC-based software interface (ToolKit or GAP) |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Humidity Tolerance | 95% RH non-condensing |

| Mounting Type | Panel mount |

| Enclosure Type | Metal, shielded, industrial |

| Dimensions (H × W × D) | 216 x 191 x 50 mm |

| Weight | 1.1 kg |

| Certifications | CE, UL, CSA (as applicable) |

Applications

Diesel and Gas Engine Control: Provides precise control for prime movers in generator sets, compressors, or pumps.

Steam and Gas Turbine Systems: Integrated control logic for speed, load, and safety functions.

Power Generation Systems: Used for automated control in standalone or parallel generator operation.

Marine and Offshore Applications: Controls propulsion engines and auxiliary generators on ships and rigs.

Industrial Automation: Provides automation logic for rotating machinery in refineries, paper mills, or mining sites.

Oil and Gas Fields: Operates engine-driven compressors or electric power systems in remote, demanding locations.

Advantages

All-in-One Digital Control: Combines governing, load sharing, start/stop logic, and monitoring in one module.

Flexible Configuration: Supports multiple I/O types and configurable parameters through software.

Robust Communication: Equipped with RS-232/RS-485 for Modbus communication; CANbus optional.

Precision Performance: Microprocessor-based control ensures stable, accurate speed and load regulation.

Wide Application Range: Suitable for turbines, engines, and gensets in industrial or marine environments.

Harsh Environment Ready: Operates in wide temperature and humidity ranges with a rugged enclosure.

Minimal Downtime: Designed for high reliability and long-term continuous operation.

Easy Integration: Compatible with legacy systems and modern digital architectures.

Reduced Footprint: Compact, panel-mounted unit reduces control cabinet space.

Global Compliance: Certified to international industrial safety and EMC standards.

Frequently Asked Questions (FAQ)

Q: What is the main use of the 9905-263 digital control module?

A: It is primarily used for controlling the speed, load, and operational logic of engines and turbines in industrial applications.

Q: Does it support remote communication?

A: Yes, it features RS-232/RS-485 serial communication and optionally CANbus for remote monitoring and control.

Q: What types of input signals can the unit process?

A: It accepts magnetic pickup (MPU), analog signals, and discrete input contacts.

Q: Can this module control generator loading and synchronization?

A: Yes, it supports load sharing and can integrate with synchronizers for multi-generator systems.

Q: What is the operating voltage range?

A: The unit operates on 18–32 VDC input, making it suitable for 24 VDC control panels.

Q: How is the unit programmed or configured?

A: Configuration is done via Woodward ToolKit or GAP software through a PC interface.

Q: Is the controller suitable for marine environments?

A: Yes, it is built with a robust enclosure and wide operating specs, making it suitable for offshore and marine use.

Q: What kind of outputs does it provide?

A: It provides PWM, analog outputs for actuators, and dry contact relays for status and alarms.

Q: Can this module operate in extreme temperatures?

A: Yes, it functions reliably from –40 °C to +70 °C.

Q: What are the dimensions and weight of the unit?

A: It measures 216 x 191 x 50 mm and weighs 1.1 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...