Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

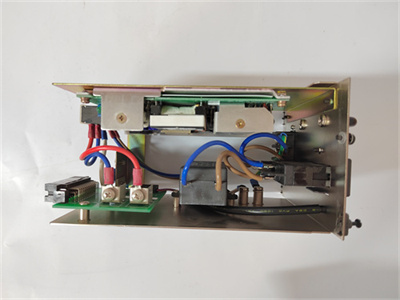

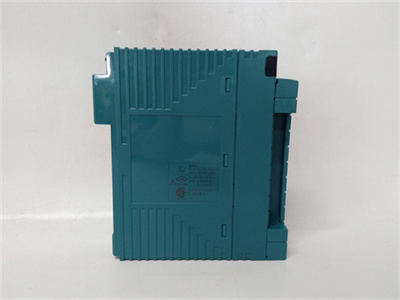

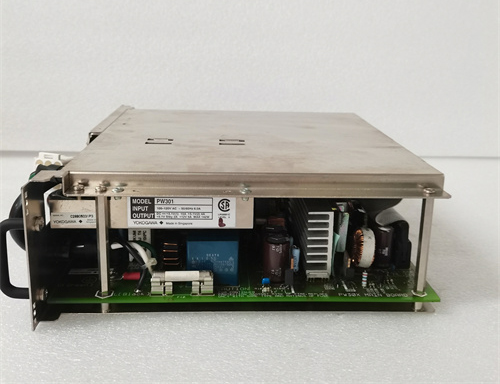

Yokogawa SSC60D Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC60D

Product Type:Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight:13 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC60D is a high-integrity Safety Control Unit designed to perform safety instrumented functions (SIFs) in compliance with IEC 61508/61511 SIL3 standards. As a part of Yokogawa’s ProSafe-RS safety instrumented system (SIS), the SSC60D plays a critical role in achieving safe and reliable plant operations in industries such as oil & gas, petrochemicals, and power generation.

The SSC60D is built for dual-redundant or simplex configurations, offering real-time diagnostics, safe-state actions, and robust fail-safe features. The unit handles safety I/O processing, logic execution, and communication with the Safety Engineering Station (SENG) via Vnet/IP, ensuring deterministic and secure data transmission.

Engineered with Yokogawa’s reputation for reliability, the SSC60D ensures compliance, flexibility, and lifecycle support, making it a cornerstone in high-performance safety system deployments.

Product Specifications

| Parameter | Description |

|---|---|

| Model | SSC60D |

| Manufacturer | Yokogawa Electric Corporation |

| Product Type | Safety Control Unit (SIL3) |

| System Compatibility | ProSafe-RS |

| Communication Interface | Vnet/IP |

| Processor Type | Dual-redundant CPU for safety control |

| Memory | 32 MB program memory; 64 MB internal log memory |

| Safety Compliance | IEC 61508 SIL3, IEC 61511 |

| Operating Voltage | 24 VDC nominal |

| Power Consumption | Approx. 10 W |

| Status Indicators | Multiple LEDs (Power, CPU Status, Communication, I/O Fault) |

| Self-Diagnostics | Yes (continuous internal checks and system diagnostics) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5–95% RH, non-condensing |

| Shock Resistance | Complies with IEC 60068 |

| Mounting | Baseplate-mounted within ProSafe-RS cabinet |

| Dimensions (W × H × D) | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Certifications | TÜV, ATEX, CE, CSA, UL, IECEx |

Product Applications

The Yokogawa SSC60D is utilized in safety-critical applications that require fail-safe operation and certified protection layers. These applications include:

-

Emergency Shutdown Systems (ESD)

Triggers plant-wide or section-specific shutdowns upon detection of unsafe conditions.

-

Burner Management Systems (BMS)

Ensures controlled start-up and safe shutdown of burners in combustion systems.

-

Fire and Gas Systems (F&G)

Monitors toxic gas levels, fire detection points, and initiates alarms or shutdowns.

-

High-Integrity Pressure Protection Systems (HIPPS)

Provides overpressure protection for pipelines and pressure vessels.

-

Turbine Protection Systems

Offers automated responses to overspeed, vibration, and lubrication system failures.

-

Critical Process Control in Hazardous Areas

Assures reliability and safety in ATEX/IECEx environments.

The SSC60D’s integration with DCS platforms like CENTUM VP enhances visibility and operational control from a unified engineering environment.

Product Advantages

-

Certified SIL3 Compliance

Assures end users of the highest levels of operational safety and system integrity.

-

Redundant Architecture

Built for high availability with CPU and communication redundancy options.

-

Secure and Deterministic Vnet/IP

Ensures safe communication between SIS components and engineering stations.

-

Powerful Diagnostic Functions

Provides detailed status, fault detection, and historical logs for preventive maintenance.

-

Compact, Modular Design

Allows flexible cabinet installation and scalable system design.

-

Integrated Engineering Environment

Compatible with Yokogawa’s SENG/ProSafe-RS engineering tools for seamless programming and simulation.

-

Fail-Safe Logic Execution

Executes safety logic reliably and transitions the plant to a safe state during abnormal events.

-

Long Lifecycle Support

Designed for 20+ years of lifecycle support under Yokogawa’s sustainable system policy.

-

Ruggedized Build

Suitable for harsh environmental conditions including high vibration and temperature variations.

-

Global Certifications

Ready for international deployments with ATEX, UL, CSA, CE, and IECEx approvals.

Frequently Asked Questions (FAQ)

-

What does the SSC60D module control?

It processes and executes safety logic for systems like ESD, F&G, BMS, and HIPPS.

-

Is the SSC60D certified for SIL3 use?

Yes, it is certified to IEC 61508 SIL3 and IEC 61511 functional safety standards.

-

Can the SSC60D be used in redundant configurations?

Absolutely. It supports dual-redundant CPUs and Vnet/IP networks.

-

Which communication protocol does it use?

It uses Yokogawa’s Vnet/IP, a high-speed and deterministic protocol.

-

Is it hot-swappable?

Modules can be replaced with minimal impact when properly configured in redundant systems.

-

What is its power requirement?

It operates on 24 VDC and typically consumes about 10 W of power.

-

How is safety logic programmed on the SSC60D?

Through Yokogawa’s Safety Engineering Station (SENG) using dedicated configuration tools.

-

What fault-tolerant features are built-in?

Includes self-diagnostics, watchdog timers, and fail-safe actions.

-

Can it be integrated with CENTUM VP?

Yes. ProSafe-RS with SSC60D is fully integrable with CENTUM VP for unified process and safety control.

-

What industries benefit most from this module?

Industries with stringent safety needs, such as oil & gas, chemical, energy, and pharmaceuticals.

Yokogawa SSC60D Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC60D

Product Type:Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight:13 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC60D is a high-integrity Safety Control Unit designed to perform safety instrumented functions (SIFs) in compliance with IEC 61508/61511 SIL3 standards. As a part of Yokogawa’s ProSafe-RS safety instrumented system (SIS), the SSC60D plays a critical role in achieving safe and reliable plant operations in industries such as oil & gas, petrochemicals, and power generation.

The SSC60D is built for dual-redundant or simplex configurations, offering real-time diagnostics, safe-state actions, and robust fail-safe features. The unit handles safety I/O processing, logic execution, and communication with the Safety Engineering Station (SENG) via Vnet/IP, ensuring deterministic and secure data transmission.

Engineered with Yokogawa’s reputation for reliability, the SSC60D ensures compliance, flexibility, and lifecycle support, making it a cornerstone in high-performance safety system deployments.

Product Specifications

| Parameter | Description |

|---|---|

| Model | SSC60D |

| Manufacturer | Yokogawa Electric Corporation |

| Product Type | Safety Control Unit (SIL3) |

| System Compatibility | ProSafe-RS |

| Communication Interface | Vnet/IP |

| Processor Type | Dual-redundant CPU for safety control |

| Memory | 32 MB program memory; 64 MB internal log memory |

| Safety Compliance | IEC 61508 SIL3, IEC 61511 |

| Operating Voltage | 24 VDC nominal |

| Power Consumption | Approx. 10 W |

| Status Indicators | Multiple LEDs (Power, CPU Status, Communication, I/O Fault) |

| Self-Diagnostics | Yes (continuous internal checks and system diagnostics) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5–95% RH, non-condensing |

| Shock Resistance | Complies with IEC 60068 |

| Mounting | Baseplate-mounted within ProSafe-RS cabinet |

| Dimensions (W × H × D) | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Certifications | TÜV, ATEX, CE, CSA, UL, IECEx |

Product Applications

The Yokogawa SSC60D is utilized in safety-critical applications that require fail-safe operation and certified protection layers. These applications include:

-

Emergency Shutdown Systems (ESD)

Triggers plant-wide or section-specific shutdowns upon detection of unsafe conditions.

-

Burner Management Systems (BMS)

Ensures controlled start-up and safe shutdown of burners in combustion systems.

-

Fire and Gas Systems (F&G)

Monitors toxic gas levels, fire detection points, and initiates alarms or shutdowns.

-

High-Integrity Pressure Protection Systems (HIPPS)

Provides overpressure protection for pipelines and pressure vessels.

-

Turbine Protection Systems

Offers automated responses to overspeed, vibration, and lubrication system failures.

-

Critical Process Control in Hazardous Areas

Assures reliability and safety in ATEX/IECEx environments.

The SSC60D’s integration with DCS platforms like CENTUM VP enhances visibility and operational control from a unified engineering environment.

Product Advantages

-

Certified SIL3 Compliance

Assures end users of the highest levels of operational safety and system integrity.

-

Redundant Architecture

Built for high availability with CPU and communication redundancy options.

-

Secure and Deterministic Vnet/IP

Ensures safe communication between SIS components and engineering stations.

-

Powerful Diagnostic Functions

Provides detailed status, fault detection, and historical logs for preventive maintenance.

-

Compact, Modular Design

Allows flexible cabinet installation and scalable system design.

-

Integrated Engineering Environment

Compatible with Yokogawa’s SENG/ProSafe-RS engineering tools for seamless programming and simulation.

-

Fail-Safe Logic Execution

Executes safety logic reliably and transitions the plant to a safe state during abnormal events.

-

Long Lifecycle Support

Designed for 20+ years of lifecycle support under Yokogawa’s sustainable system policy.

-

Ruggedized Build

Suitable for harsh environmental conditions including high vibration and temperature variations.

-

Global Certifications

Ready for international deployments with ATEX, UL, CSA, CE, and IECEx approvals.

Frequently Asked Questions (FAQ)

-

What does the SSC60D module control?

It processes and executes safety logic for systems like ESD, F&G, BMS, and HIPPS.

-

Is the SSC60D certified for SIL3 use?

Yes, it is certified to IEC 61508 SIL3 and IEC 61511 functional safety standards.

-

Can the SSC60D be used in redundant configurations?

Absolutely. It supports dual-redundant CPUs and Vnet/IP networks.

-

Which communication protocol does it use?

It uses Yokogawa’s Vnet/IP, a high-speed and deterministic protocol.

-

Is it hot-swappable?

Modules can be replaced with minimal impact when properly configured in redundant systems.

-

What is its power requirement?

It operates on 24 VDC and typically consumes about 10 W of power.

-

How is safety logic programmed on the SSC60D?

Through Yokogawa’s Safety Engineering Station (SENG) using dedicated configuration tools.

-

What fault-tolerant features are built-in?

Includes self-diagnostics, watchdog timers, and fail-safe actions.

-

Can it be integrated with CENTUM VP?

Yes. ProSafe-RS with SSC60D is fully integrable with CENTUM VP for unified process and safety control.

-

What industries benefit most from this module?

Industries with stringent safety needs, such as oil & gas, chemical, energy, and pharmaceuticals.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...