Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

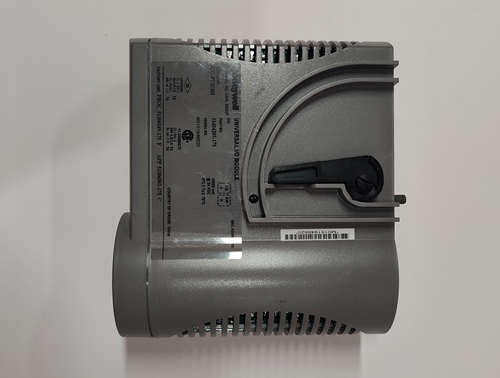

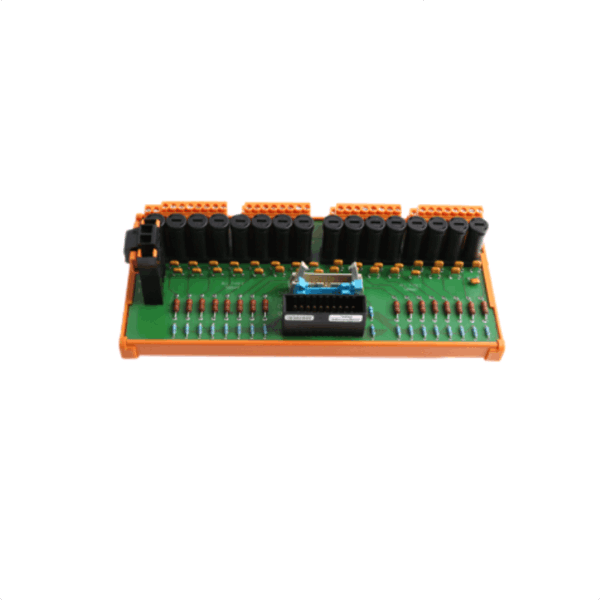

Honeywell FC-TSGASH-1624P Field Terminal Module Assemblies

Manufacturer:Honeywell

Product Number:FC-TSGASH-1624P

Condition:Field Terminal Module Assemblies

Origin:USA

Dimensions:261 × 194 × 52 mm

Weight:1.8 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-TSGASH-1624P is a high-performance Gas Sensor Analog Input Module designed for use within the Experion PKS and C300 control system architectures. This module offers reliable and accurate analog signal processing, specifically tailored for gas detection applications in industrial environments such as oil & gas, petrochemical, and power generation sectors. It accepts analog inputs from various field devices, conditions the signals, and communicates with the controller for real-time monitoring and safety responses. Engineered with Honeywell’s robust I/O technology, this module is DIN rail mountable and provides hot-swappable capabilities for maintenance efficiency.

Product Advantages

-

High-accuracy analog signal processing optimized for gas sensor input.

-

Robust noise immunity ensures reliable performance in electrically noisy industrial environments.

-

Hot-swappable design allows replacement without system shutdown, minimizing downtime.

-

Compliant with safety standards such as SIL2 (IEC61508), making it suitable for critical safety applications.

-

Compact footprint suitable for dense control cabinets.

-

Seamless integration into the Honeywell C300 or Experion system platforms.

-

Extended temperature operation range, allowing usage in harsh field conditions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | FC-TSGASH-1624P |

| Description | Gas Sensor Analog Input Module |

| Input Channels | 16 analog channels |

| Input Type | 4–20 mA loop-powered inputs (gas sensors) |

| Resolution | 16-bit |

| Isolation | Channel-to-bus and channel-to-channel |

| Signal Accuracy | ±0.05% full scale |

| Input Impedance | 250 Ohms |

| Power Supply | 24 VDC nominal |

| Power Consumption | < 6 W |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Communication Protocol | FTE (Fault Tolerant Ethernet) |

| Mounting | DIN rail |

| Hot Swap Capability | Yes |

| Dimensions | 261 × 194 × 52 mm |

| Weight | 1.8 kg |

| Certifications | CE, CSA, ATEX, SIL2 |

Product Applications

-

Oil & Gas Facilities – Real-time gas detection, safety shutdown input, process gas monitoring.

-

Chemical Processing Plants – Monitoring of hazardous gases, emissions tracking.

-

Power Generation – Combustion control, flue gas monitoring, emissions compliance.

-

Pharmaceutical Manufacturing – Cleanroom gas environment monitoring.

-

Industrial Safety Systems – Part of ESD (Emergency Shutdown) or F&G (Fire and Gas) systems.

Installation Instructions

-

Ensure the module is installed on a DIN rail within a certified Honeywell I/O chassis.

-

Connect each gas sensor’s 4–20 mA output to one of the 16 input channels using shielded twisted pair wiring.

-

Connect the module to the Honeywell C300 or equivalent controller using FTE (Fault Tolerant Ethernet).

-

Power the module using a regulated 24 VDC supply, ensuring correct polarity.

-

Configure the I/O channels using Honeywell Control Builder software.

-

If replacing, use hot-swap functionality without system shutdown.

-

Ensure grounding and shielding are consistent with Honeywell wiring standards to reduce noise.

-

Confirm channel diagnostics via the system interface after installation.

Frequently Asked Questions (FAQ)

Q1: What types of sensors are compatible with the FC-TSGASH-1624P?

A1: It supports analog gas sensors that output 4–20 mA signals, such as catalytic bead, infrared, and electrochemical gas sensors.

Q2: Can the module be replaced while the system is running?

A2: Yes, it features hot-swapping capabilities, allowing maintenance without interrupting operation.

Q3: Is it suitable for hazardous area installations?

A3: Yes, it carries ATEX certification and is often deployed in Zone 2 environments.

Q4: How many channels can be used simultaneously?

A4: All 16 analog channels can be used concurrently with full isolation.

Q5: Does the module support HART communication?

A5: No, the FC-TSGASH-1624P is designed for standard 4–20 mA analog input and does not process HART signals.

Q6: What is the typical response time of the analog input?

A6: The input update rate is typically less than 50 ms per channel, ensuring rapid response.

Q7: Can it be integrated with third-party systems?

A7: It is optimized for Honeywell Experion/C300 systems; integration with third-party systems may require protocol converters.

Q8: How is electrical isolation achieved?

A8: The module features both channel-to-channel and channel-to-bus isolation to prevent cross-talk and protect the system.

Q9: What happens in case of a sensor wiring fault?

A9: Built-in diagnostics detect open-loop or short-circuit conditions and alert the controller.

Q10: Is calibration of the module required?

A10: The module is factory-calibrated; however, periodic calibration of the connected sensors is recommended for accuracy.

Honeywell FC-TSGASH-1624P Field Terminal Module Assemblies

Manufacturer:Honeywell

Product Number:FC-TSGASH-1624P

Condition:Field Terminal Module Assemblies

Origin:USA

Dimensions:261 × 194 × 52 mm

Weight:1.8 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-TSGASH-1624P is a high-performance Gas Sensor Analog Input Module designed for use within the Experion PKS and C300 control system architectures. This module offers reliable and accurate analog signal processing, specifically tailored for gas detection applications in industrial environments such as oil & gas, petrochemical, and power generation sectors. It accepts analog inputs from various field devices, conditions the signals, and communicates with the controller for real-time monitoring and safety responses. Engineered with Honeywell’s robust I/O technology, this module is DIN rail mountable and provides hot-swappable capabilities for maintenance efficiency.

Product Advantages

-

High-accuracy analog signal processing optimized for gas sensor input.

-

Robust noise immunity ensures reliable performance in electrically noisy industrial environments.

-

Hot-swappable design allows replacement without system shutdown, minimizing downtime.

-

Compliant with safety standards such as SIL2 (IEC61508), making it suitable for critical safety applications.

-

Compact footprint suitable for dense control cabinets.

-

Seamless integration into the Honeywell C300 or Experion system platforms.

-

Extended temperature operation range, allowing usage in harsh field conditions.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | FC-TSGASH-1624P |

| Description | Gas Sensor Analog Input Module |

| Input Channels | 16 analog channels |

| Input Type | 4–20 mA loop-powered inputs (gas sensors) |

| Resolution | 16-bit |

| Isolation | Channel-to-bus and channel-to-channel |

| Signal Accuracy | ±0.05% full scale |

| Input Impedance | 250 Ohms |

| Power Supply | 24 VDC nominal |

| Power Consumption | < 6 W |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Communication Protocol | FTE (Fault Tolerant Ethernet) |

| Mounting | DIN rail |

| Hot Swap Capability | Yes |

| Dimensions | 261 × 194 × 52 mm |

| Weight | 1.8 kg |

| Certifications | CE, CSA, ATEX, SIL2 |

Product Applications

-

Oil & Gas Facilities – Real-time gas detection, safety shutdown input, process gas monitoring.

-

Chemical Processing Plants – Monitoring of hazardous gases, emissions tracking.

-

Power Generation – Combustion control, flue gas monitoring, emissions compliance.

-

Pharmaceutical Manufacturing – Cleanroom gas environment monitoring.

-

Industrial Safety Systems – Part of ESD (Emergency Shutdown) or F&G (Fire and Gas) systems.

Installation Instructions

-

Ensure the module is installed on a DIN rail within a certified Honeywell I/O chassis.

-

Connect each gas sensor’s 4–20 mA output to one of the 16 input channels using shielded twisted pair wiring.

-

Connect the module to the Honeywell C300 or equivalent controller using FTE (Fault Tolerant Ethernet).

-

Power the module using a regulated 24 VDC supply, ensuring correct polarity.

-

Configure the I/O channels using Honeywell Control Builder software.

-

If replacing, use hot-swap functionality without system shutdown.

-

Ensure grounding and shielding are consistent with Honeywell wiring standards to reduce noise.

-

Confirm channel diagnostics via the system interface after installation.

Frequently Asked Questions (FAQ)

Q1: What types of sensors are compatible with the FC-TSGASH-1624P?

A1: It supports analog gas sensors that output 4–20 mA signals, such as catalytic bead, infrared, and electrochemical gas sensors.

Q2: Can the module be replaced while the system is running?

A2: Yes, it features hot-swapping capabilities, allowing maintenance without interrupting operation.

Q3: Is it suitable for hazardous area installations?

A3: Yes, it carries ATEX certification and is often deployed in Zone 2 environments.

Q4: How many channels can be used simultaneously?

A4: All 16 analog channels can be used concurrently with full isolation.

Q5: Does the module support HART communication?

A5: No, the FC-TSGASH-1624P is designed for standard 4–20 mA analog input and does not process HART signals.

Q6: What is the typical response time of the analog input?

A6: The input update rate is typically less than 50 ms per channel, ensuring rapid response.

Q7: Can it be integrated with third-party systems?

A7: It is optimized for Honeywell Experion/C300 systems; integration with third-party systems may require protocol converters.

Q8: How is electrical isolation achieved?

A8: The module features both channel-to-channel and channel-to-bus isolation to prevent cross-talk and protect the system.

Q9: What happens in case of a sensor wiring fault?

A9: Built-in diagnostics detect open-loop or short-circuit conditions and alert the controller.

Q10: Is calibration of the module required?

A10: The module is factory-calibrated; however, periodic calibration of the connected sensors is recommended for accuracy.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...