Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

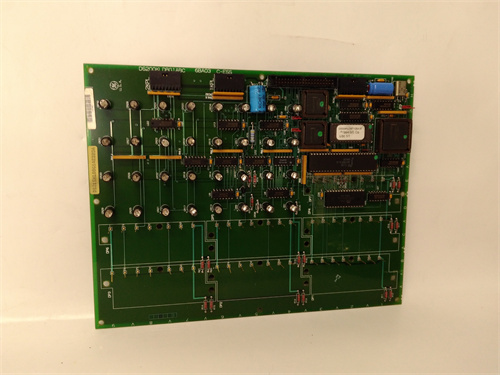

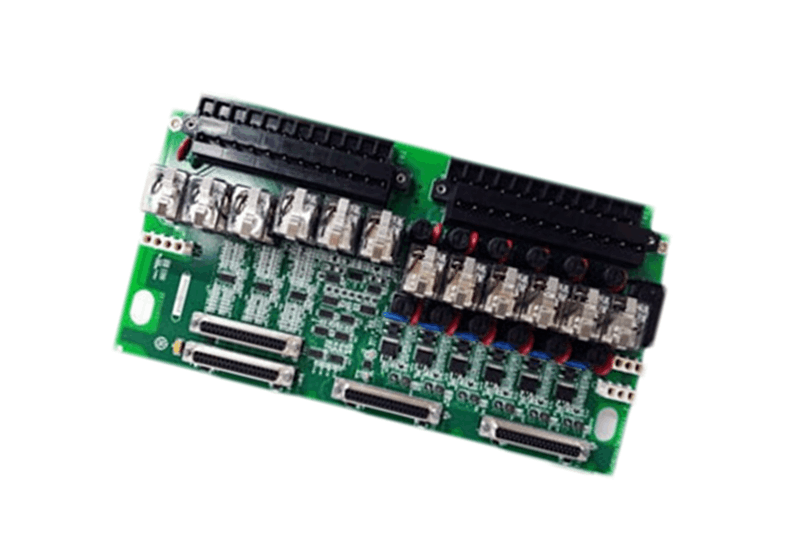

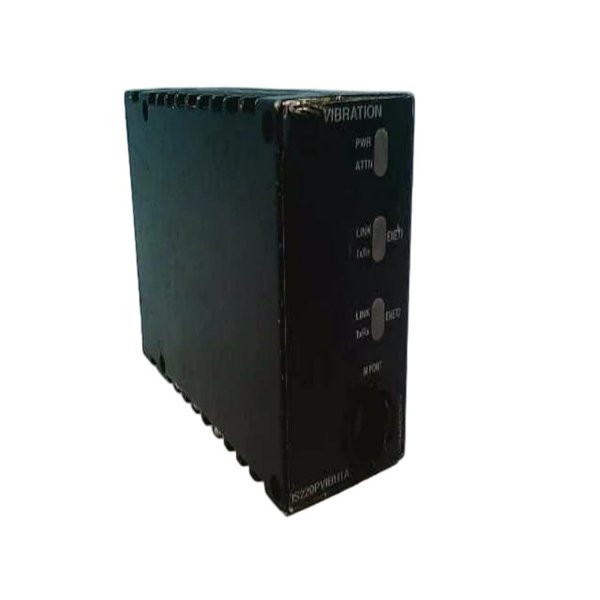

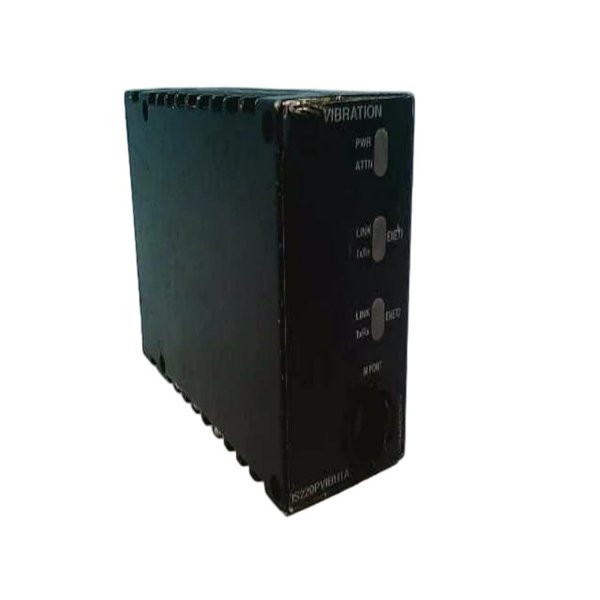

General Electric IS220PVIBH1AD Vibration Monitor

Manufacturer:GE

Product Number:IS220PVIBH1AD

Product Type:Vibration Monitor

Origin:USA

Dimensions:82.6 x 41.9 x 121mm

Weight:0.44kg

Views:131

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS220PVIBH1AD is a high-performance vibration monitoring device designed for use in industrial applications, particularly for condition monitoring of rotating machinery such as motors, turbines, and pumps. This device plays a crucial role in detecting and diagnosing potential faults in machinery before they lead to costly downtimes or catastrophic failures. The IS220PVIBH1AD integrates seamlessly with other GE control systems, providing a comprehensive solution for continuous machinery health monitoring.

The IS220PVIBH1AD features advanced vibration analysis capabilities, offering real-time measurements of vibration levels, displacement, and other important indicators of machinery health. It is an essential component in predictive maintenance programs aimed at reducing operational disruptions, extending the lifespan of machinery, and ensuring the safety of critical assets.

Product Specifications

| Feature | Specification |

|---|---|

| Model | IS220PVIBH1AD |

| Type | Vibration Monitoring Device |

| Dimensions | 82.6 x 41.9 x 121 mm |

| Weight | 0.44 kg |

| Input Type | Vibration signal input (dynamic displacement) |

| Output Type | Analog and digital outputs |

| Measurement Range | Wide vibration frequency range |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 24V DC |

| Mounting Type | Panel mounting |

| Compatibility | Works with GE’s Mark VIe and other GE systems |

| Signal Conditioning | Built-in signal conditioning and filtering |

| Vibration Parameters | Acceleration, velocity, displacement, phase angle |

Applications

The GE IS220PVIBH1AD Vibration Monitor is designed to monitor and protect critical rotating machinery in various industrial applications, including:

-

Turbine Monitoring: Used to monitor the vibration levels of turbines to prevent failure and optimize operational efficiency.

-

Motor and Pump Monitoring: Detects imbalances or misalignments in motors and pumps, reducing wear and avoiding unexpected breakdowns.

-

Compressor Health Monitoring: Helps to monitor compressors used in industries such as oil & gas, power generation, and chemical plants.

-

Rotating Equipment Condition Monitoring: Suitable for all rotating equipment where vibration is a key indicator of health and performance.

-

Predictive Maintenance: Essential in predictive maintenance programs, providing early detection of mechanical faults to minimize downtime and repair costs.

Product Advantages

-

High-Precision Vibration Measurement: The IS220PVIBH1AD provides precise and reliable vibration measurements, making it an ideal choice for condition-based monitoring of critical rotating machinery.

-

Integration with GE Systems: It integrates seamlessly with GE’s Mark VIe control systems and other GE monitoring platforms, enabling real-time data collection and analysis.

-

Durability: Designed for harsh industrial environments, the monitor is built to operate in extreme temperatures and tough conditions, ensuring long-term reliability.

-

Early Fault Detection: The device offers early detection of faults such as imbalance, misalignment, and bearing wear, helping to prevent catastrophic failures and reduce downtime.

-

Comprehensive Monitoring: It provides measurements of key vibration parameters such as acceleration, velocity, displacement, and phase angle, allowing for a comprehensive assessment of machinery health.

-

Signal Conditioning: The device includes built-in signal conditioning capabilities, offering filtered and processed data for more accurate and actionable insights.

-

Cost-Effective: By enabling predictive maintenance, the IS220PVIBH1AD reduces maintenance costs, increases operational efficiency, and extends the life of machinery.

-

Easy Installation: The monitor supports panel mounting, making it easy to install and integrate into existing setups without major changes to the system.

FAQ

1. How does the GE IS220PVIBH1AD monitor vibration?

The IS220PVIBH1AD monitors vibration using dynamic displacement sensors to measure the vibration levels of rotating machinery. It can detect key parameters such as acceleration, velocity, and displacement.

2. What types of outputs are supported by the IS220PVIBH1AD?

The monitor provides both analog and digital outputs, enabling it to be easily integrated with GE’s control systems and third-party monitoring platforms.

3. What machinery can the IS220PVIBH1AD be used to monitor?

The IS220PVIBH1AD is used for vibration monitoring of rotating equipment such as turbines, motors, compressors, and pumps, making it ideal for industries like oil and gas, power generation, and manufacturing.

4. How does the IS220PVIBH1AD contribute to predictive maintenance?

By providing real-time vibration measurements, the IS220PVIBH1AD helps identify early signs of mechanical faults like imbalance, misalignment, and bearing wear, which can be addressed before they cause unplanned downtime or failure.

5. Can the IS220PVIBH1AD be used in extreme environments?

Yes, the IS220PVIBH1AD operates within a temperature range of -40°C to +85°C, making it suitable for harsh industrial environments where vibration monitoring is critical.

6. Does the IS220PVIBH1AD require external signal conditioning?

No, the IS220PVIBH1AD includes built-in signal conditioning, which processes the vibration signals before sending them to the control system, ensuring accurate and reliable data.

7. What kind of power supply does the IS220PVIBH1AD require?

The IS220PVIBH1AD operates on a 24V DC power supply, making it compatible with most industrial power systems.

8. How is the IS220PVIBH1AD installed?

The IS220PVIBH1AD supports panel mounting, allowing for easy installation in control cabinets or other panel-based setups.

9. What vibration parameters can the IS220PVIBH1AD measure?

The IS220PVIBH1AD can measure key vibration parameters including acceleration, velocity, displacement, and phase angle, which are critical for machinery health monitoring.

10. Is the IS220PVIBH1AD compatible with other GE systems?

Yes, the IS220PVIBH1AD integrates seamlessly with GE’s Mark VIe control systems and other GE monitoring platforms, providing a unified solution for vibration and condition monitoring.

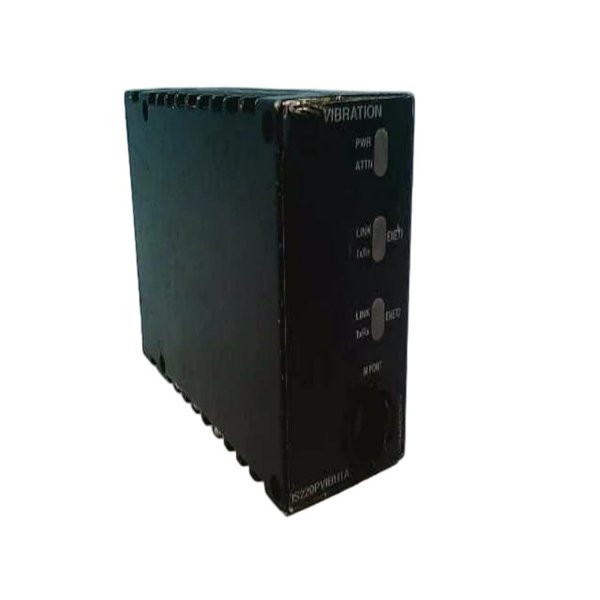

General Electric IS220PVIBH1AD Vibration Monitor

Manufacturer:GE

Product Number:IS220PVIBH1AD

Product Type:Vibration Monitor

Origin:USA

Dimensions:82.6 x 41.9 x 121mm

Weight:0.44kg

Views:131

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS220PVIBH1AD is a high-performance vibration monitoring device designed for use in industrial applications, particularly for condition monitoring of rotating machinery such as motors, turbines, and pumps. This device plays a crucial role in detecting and diagnosing potential faults in machinery before they lead to costly downtimes or catastrophic failures. The IS220PVIBH1AD integrates seamlessly with other GE control systems, providing a comprehensive solution for continuous machinery health monitoring.

The IS220PVIBH1AD features advanced vibration analysis capabilities, offering real-time measurements of vibration levels, displacement, and other important indicators of machinery health. It is an essential component in predictive maintenance programs aimed at reducing operational disruptions, extending the lifespan of machinery, and ensuring the safety of critical assets.

Product Specifications

| Feature | Specification |

|---|---|

| Model | IS220PVIBH1AD |

| Type | Vibration Monitoring Device |

| Dimensions | 82.6 x 41.9 x 121 mm |

| Weight | 0.44 kg |

| Input Type | Vibration signal input (dynamic displacement) |

| Output Type | Analog and digital outputs |

| Measurement Range | Wide vibration frequency range |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 24V DC |

| Mounting Type | Panel mounting |

| Compatibility | Works with GE’s Mark VIe and other GE systems |

| Signal Conditioning | Built-in signal conditioning and filtering |

| Vibration Parameters | Acceleration, velocity, displacement, phase angle |

Applications

The GE IS220PVIBH1AD Vibration Monitor is designed to monitor and protect critical rotating machinery in various industrial applications, including:

-

Turbine Monitoring: Used to monitor the vibration levels of turbines to prevent failure and optimize operational efficiency.

-

Motor and Pump Monitoring: Detects imbalances or misalignments in motors and pumps, reducing wear and avoiding unexpected breakdowns.

-

Compressor Health Monitoring: Helps to monitor compressors used in industries such as oil & gas, power generation, and chemical plants.

-

Rotating Equipment Condition Monitoring: Suitable for all rotating equipment where vibration is a key indicator of health and performance.

-

Predictive Maintenance: Essential in predictive maintenance programs, providing early detection of mechanical faults to minimize downtime and repair costs.

Product Advantages

-

High-Precision Vibration Measurement: The IS220PVIBH1AD provides precise and reliable vibration measurements, making it an ideal choice for condition-based monitoring of critical rotating machinery.

-

Integration with GE Systems: It integrates seamlessly with GE’s Mark VIe control systems and other GE monitoring platforms, enabling real-time data collection and analysis.

-

Durability: Designed for harsh industrial environments, the monitor is built to operate in extreme temperatures and tough conditions, ensuring long-term reliability.

-

Early Fault Detection: The device offers early detection of faults such as imbalance, misalignment, and bearing wear, helping to prevent catastrophic failures and reduce downtime.

-

Comprehensive Monitoring: It provides measurements of key vibration parameters such as acceleration, velocity, displacement, and phase angle, allowing for a comprehensive assessment of machinery health.

-

Signal Conditioning: The device includes built-in signal conditioning capabilities, offering filtered and processed data for more accurate and actionable insights.

-

Cost-Effective: By enabling predictive maintenance, the IS220PVIBH1AD reduces maintenance costs, increases operational efficiency, and extends the life of machinery.

-

Easy Installation: The monitor supports panel mounting, making it easy to install and integrate into existing setups without major changes to the system.

FAQ

1. How does the GE IS220PVIBH1AD monitor vibration?

The IS220PVIBH1AD monitors vibration using dynamic displacement sensors to measure the vibration levels of rotating machinery. It can detect key parameters such as acceleration, velocity, and displacement.

2. What types of outputs are supported by the IS220PVIBH1AD?

The monitor provides both analog and digital outputs, enabling it to be easily integrated with GE’s control systems and third-party monitoring platforms.

3. What machinery can the IS220PVIBH1AD be used to monitor?

The IS220PVIBH1AD is used for vibration monitoring of rotating equipment such as turbines, motors, compressors, and pumps, making it ideal for industries like oil and gas, power generation, and manufacturing.

4. How does the IS220PVIBH1AD contribute to predictive maintenance?

By providing real-time vibration measurements, the IS220PVIBH1AD helps identify early signs of mechanical faults like imbalance, misalignment, and bearing wear, which can be addressed before they cause unplanned downtime or failure.

5. Can the IS220PVIBH1AD be used in extreme environments?

Yes, the IS220PVIBH1AD operates within a temperature range of -40°C to +85°C, making it suitable for harsh industrial environments where vibration monitoring is critical.

6. Does the IS220PVIBH1AD require external signal conditioning?

No, the IS220PVIBH1AD includes built-in signal conditioning, which processes the vibration signals before sending them to the control system, ensuring accurate and reliable data.

7. What kind of power supply does the IS220PVIBH1AD require?

The IS220PVIBH1AD operates on a 24V DC power supply, making it compatible with most industrial power systems.

8. How is the IS220PVIBH1AD installed?

The IS220PVIBH1AD supports panel mounting, allowing for easy installation in control cabinets or other panel-based setups.

9. What vibration parameters can the IS220PVIBH1AD measure?

The IS220PVIBH1AD can measure key vibration parameters including acceleration, velocity, displacement, and phase angle, which are critical for machinery health monitoring.

10. Is the IS220PVIBH1AD compatible with other GE systems?

Yes, the IS220PVIBH1AD integrates seamlessly with GE’s Mark VIe control systems and other GE monitoring platforms, providing a unified solution for vibration and condition monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...