Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

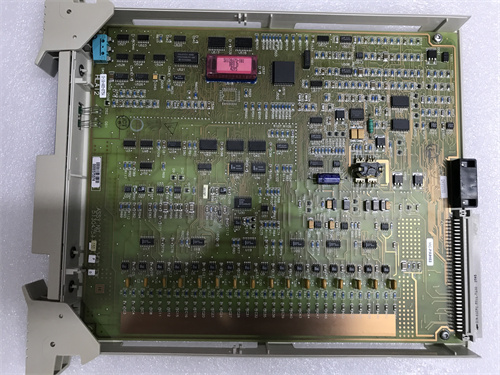

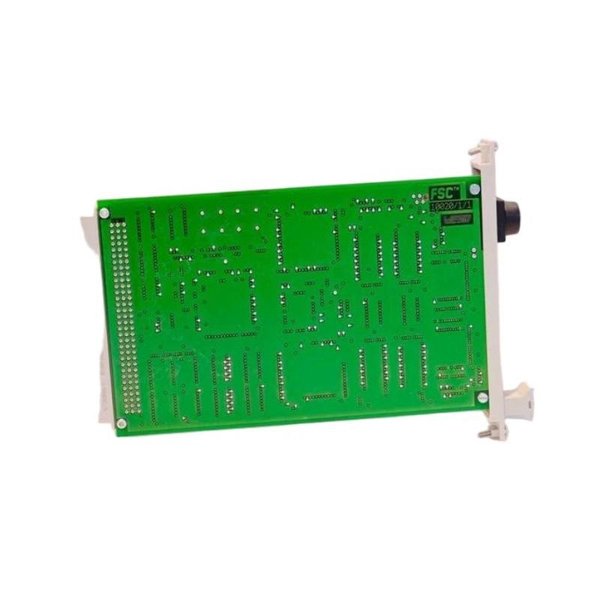

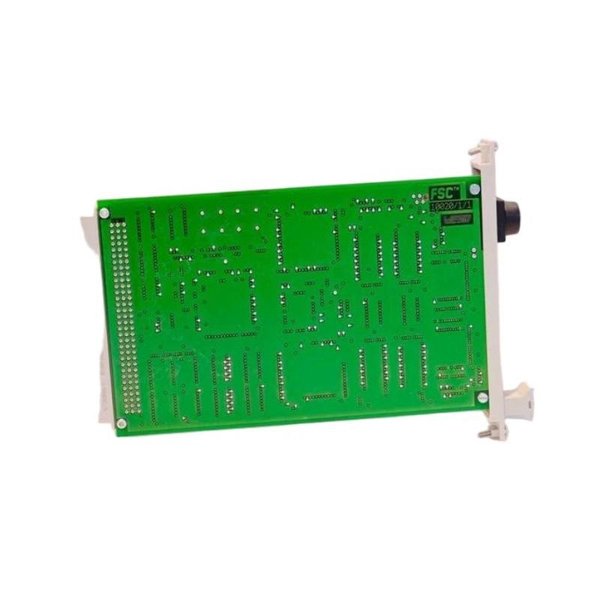

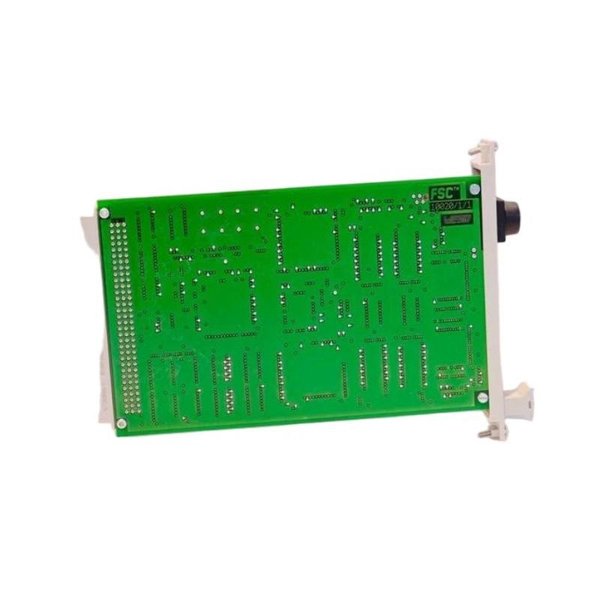

Honeywell FSC 10020/1/2 FSC CPU Module

Manufacturer:Honeywell

Product Number:FSC 10020/1/2

Condition:FSC CPU Module

Origin:USA

Dimensions:172 x 102 x 41 mm

Weight:0.5 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

As part of the TÜV-certified Safety Manager family, the FSC 10020/1/2 plays a crucial role in meeting IEC 61508 SIL3 safety standards. It forms a central processing component of the FSC system, offering robust diagnostic capabilities, redundancy, and real-time response under emergency conditions.

Product Features and Advantages

-

High Reliability: Redundant architecture for maximum uptime and safety compliance.

-

SIL3 Certified: Complies with IEC 61508 standards for functional safety.

-

Diagnostic Capabilities: Built-in self-testing, automatic fault detection, and isolation.

-

Modular Design: Easy to integrate with other FSC modules and scalable based on plant size.

-

Deterministic Response: Ensures rapid and predictable system reactions in emergencies.

-

Lifecycle Support: Backed by Honeywell’s global support infrastructure for long-term use.

-

Interoperability: Seamlessly integrates with Experion PKS and other DCS/SCADA systems.

-

Hot Swappable: Modules can be replaced without shutting down the system.

-

Event Logging: Secure event logging helps with root cause analysis and compliance reporting.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | FSC 10020/1/2 |

| System | Honeywell Safety Manager (FSC) |

| Function | Logic processing/controller module |

| Safety Certification | SIL3 (IEC 61508) |

| Processor Type | Redundant Safety CPU |

| Communication Interface | RS485, Ethernet, proprietary I/O bus |

| Operating Voltage | 24 VDC nominal |

| Power Consumption | 12 W per module |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% – 95% non-condensing |

| Enclosure Type | Plug-in module for backplane mounting |

| Dimensions | 172 x 102 x 41 mm |

| Weight | 0.5 kg |

| Redundancy Support | Yes (CPU, communication, power) |

| Compatible Systems | FSC racks, Safety Manager, Experion PKS |

| Installation Mounting | Backplane plug-in with locking mechanism |

Applications

The FSC 10020/1/2 module is widely deployed in industries where safety is paramount and fail-safe logic is required:

-

Oil & Gas: Emergency shutdown systems (ESD), fire and gas systems (F&G), and blowout preventer logic.

-

Refineries: Burner management systems (BMS), high-integrity pressure protection systems (HIPPS).

-

Power Generation: Boiler protection and turbine trip systems.

-

Chemical Processing: Toxic gas monitoring, interlock logic for hazardous operations.

-

Water & Wastewater: Critical treatment process logic under safety constraints.

-

Pharmaceutical: Bio-reactor control, hazardous area logic enforcement.

Installation Instructions

-

Power Down the FSC Rack before inserting or replacing the module unless hot-swapping is permitted and supported.

-

Insert the 10020/1/2 Module into the designated slot on the FSC backplane.

-

Secure the Locking Mechanism to ensure physical stability.

-

Connect Communication Cables for redundant Ethernet, RS485, or proprietary bus.

-

Configure the Module via FSC Engineering Tool, uploading the safety logic and validating using Honeywell diagnostic software.

-

Perform System Self-Test to ensure full recognition and functionality.

-

Commissioning: Conduct a full I/O validation and fail-safe test before operational deployment.

FAQs

Q1: What role does the FSC 10020/1/2 module play in a safety system?

A1: It functions as the logic solver, processing safety-critical signals and executing actions such as shutdowns or alarms when unsafe conditions arise.

Q2: Can the module be used in explosive environments?

A2: While the module itself isn’t certified for hazardous zones, it can control intrinsically safe field I/O via isolators and barriers.

Q3: Does it support redundant operation?

A3: Yes, it supports full CPU and communication redundancy, essential for high-availability applications.

Q4: What tools are required for programming the 10020/1/2 module?

A4: Honeywell’s Safety Builder and Safety Manager Configuration Tools are typically used for engineering and diagnostics.

Q5: Is the module compatible with older FSC racks?

A5: Generally, yes. However, firmware compatibility and rack generation should be verified.

Q6: What happens during a CPU failure?

A6: The redundant CPU automatically takes over without interrupting safety logic execution.

Q7: Can I update firmware remotely?

A7: Firmware updates should be done locally under maintenance windows to minimize risk, although remote update options exist in newer systems.

Q8: What certifications does the FSC 10020/1/2 carry?

A8: It is TÜV-certified for SIL3 safety compliance according to IEC 61508.

Q9: How long is the typical lifecycle of this module?

A9: With proper maintenance, the service life typically exceeds 5 years.

Q10: Is logging available for diagnostics?

A10: Yes, the module records detailed diagnostics, fault events, and test logs that are accessible via software tools.

Honeywell FSC 10020/1/2 FSC CPU Module

Manufacturer:Honeywell

Product Number:FSC 10020/1/2

Condition:FSC CPU Module

Origin:USA

Dimensions:172 x 102 x 41 mm

Weight:0.5 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

As part of the TÜV-certified Safety Manager family, the FSC 10020/1/2 plays a crucial role in meeting IEC 61508 SIL3 safety standards. It forms a central processing component of the FSC system, offering robust diagnostic capabilities, redundancy, and real-time response under emergency conditions.

Product Features and Advantages

-

High Reliability: Redundant architecture for maximum uptime and safety compliance.

-

SIL3 Certified: Complies with IEC 61508 standards for functional safety.

-

Diagnostic Capabilities: Built-in self-testing, automatic fault detection, and isolation.

-

Modular Design: Easy to integrate with other FSC modules and scalable based on plant size.

-

Deterministic Response: Ensures rapid and predictable system reactions in emergencies.

-

Lifecycle Support: Backed by Honeywell’s global support infrastructure for long-term use.

-

Interoperability: Seamlessly integrates with Experion PKS and other DCS/SCADA systems.

-

Hot Swappable: Modules can be replaced without shutting down the system.

-

Event Logging: Secure event logging helps with root cause analysis and compliance reporting.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | FSC 10020/1/2 |

| System | Honeywell Safety Manager (FSC) |

| Function | Logic processing/controller module |

| Safety Certification | SIL3 (IEC 61508) |

| Processor Type | Redundant Safety CPU |

| Communication Interface | RS485, Ethernet, proprietary I/O bus |

| Operating Voltage | 24 VDC nominal |

| Power Consumption | 12 W per module |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% – 95% non-condensing |

| Enclosure Type | Plug-in module for backplane mounting |

| Dimensions | 172 x 102 x 41 mm |

| Weight | 0.5 kg |

| Redundancy Support | Yes (CPU, communication, power) |

| Compatible Systems | FSC racks, Safety Manager, Experion PKS |

| Installation Mounting | Backplane plug-in with locking mechanism |

Applications

The FSC 10020/1/2 module is widely deployed in industries where safety is paramount and fail-safe logic is required:

-

Oil & Gas: Emergency shutdown systems (ESD), fire and gas systems (F&G), and blowout preventer logic.

-

Refineries: Burner management systems (BMS), high-integrity pressure protection systems (HIPPS).

-

Power Generation: Boiler protection and turbine trip systems.

-

Chemical Processing: Toxic gas monitoring, interlock logic for hazardous operations.

-

Water & Wastewater: Critical treatment process logic under safety constraints.

-

Pharmaceutical: Bio-reactor control, hazardous area logic enforcement.

Installation Instructions

-

Power Down the FSC Rack before inserting or replacing the module unless hot-swapping is permitted and supported.

-

Insert the 10020/1/2 Module into the designated slot on the FSC backplane.

-

Secure the Locking Mechanism to ensure physical stability.

-

Connect Communication Cables for redundant Ethernet, RS485, or proprietary bus.

-

Configure the Module via FSC Engineering Tool, uploading the safety logic and validating using Honeywell diagnostic software.

-

Perform System Self-Test to ensure full recognition and functionality.

-

Commissioning: Conduct a full I/O validation and fail-safe test before operational deployment.

FAQs

Q1: What role does the FSC 10020/1/2 module play in a safety system?

A1: It functions as the logic solver, processing safety-critical signals and executing actions such as shutdowns or alarms when unsafe conditions arise.

Q2: Can the module be used in explosive environments?

A2: While the module itself isn’t certified for hazardous zones, it can control intrinsically safe field I/O via isolators and barriers.

Q3: Does it support redundant operation?

A3: Yes, it supports full CPU and communication redundancy, essential for high-availability applications.

Q4: What tools are required for programming the 10020/1/2 module?

A4: Honeywell’s Safety Builder and Safety Manager Configuration Tools are typically used for engineering and diagnostics.

Q5: Is the module compatible with older FSC racks?

A5: Generally, yes. However, firmware compatibility and rack generation should be verified.

Q6: What happens during a CPU failure?

A6: The redundant CPU automatically takes over without interrupting safety logic execution.

Q7: Can I update firmware remotely?

A7: Firmware updates should be done locally under maintenance windows to minimize risk, although remote update options exist in newer systems.

Q8: What certifications does the FSC 10020/1/2 carry?

A8: It is TÜV-certified for SIL3 safety compliance according to IEC 61508.

Q9: How long is the typical lifecycle of this module?

A9: With proper maintenance, the service life typically exceeds 5 years.

Q10: Is logging available for diagnostics?

A10: Yes, the module records detailed diagnostics, fault events, and test logs that are accessible via software tools.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...