Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

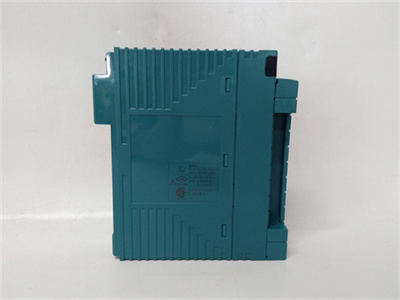

Yokogawa EB401 ER Bus Interface Master Module

Manufacturer:Yokogawa

Product Number:EB401

Product Type:ER Bus Interface Master Module

Origin:Japan

Dimensions:144.65 x 130 x 32.8 mm

Weight:0.3 kg

Views:82

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

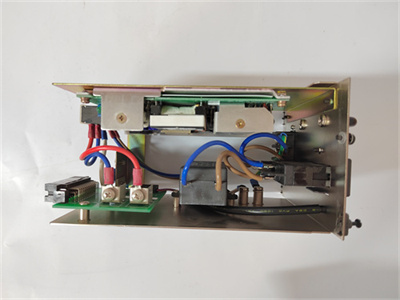

The Yokogawa EB401 ER Bus Interface Master Module is a key component within Yokogawa’s distributed control systems (DCS). It serves as the master interface for the ER Bus communication network, enabling high-speed, reliable data exchange between system controllers and remote I/O modules.

Designed for mission-critical industrial applications, EB401 supports redundancy, fault detection, and self-diagnostics to ensure uninterrupted communication. Its robust design makes it suitable for harsh environments, commonly seen in industries like oil & gas, power generation, and petrochemicals.

Product Specifications

| Parameter | Description |

|---|---|

| Model | EB401 |

| Function | ER Bus Interface Master Module |

| Communication Protocol | ER Bus |

| Data Transfer Mode | High-speed synchronous communication |

| Power Supply | 24 V DC (nominal) |

| Power Consumption | Approx. 6 W |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% to 95% RH (non-condensing) |

| Installation Method | Rack-mounted within System Rack |

| Compliance | CE, RoHS |

| Redundancy Support | Yes |

| Diagnostic Features | Self-diagnostic, Error Detection, LED Status |

| Dimensions (H × W × D) | 144.65 x 130 x 32.8 mm |

| Weight | 0.3 kg |

Applications

-

Distributed Control Systems (DCS): Ensures real-time communication between control units and remote I/O.

-

Process Automation: Provides high-speed, reliable data exchange for complex industrial processes.

-

Redundant Safety Systems: Maintains continuous operation in safety-critical environments.

-

Power Generation Plants: Optimizes control and monitoring for energy production facilities.

-

Oil & Gas Operations: Guarantees data reliability for upstream and downstream processes.

-

Petrochemical Industry: Handles communication in hazardous process conditions.

Product Advantages

-

High-Speed Communication: Supports synchronous data exchange with minimal latency.

-

Redundancy Design: Dual-channel ER bus ensures uninterrupted operation.

-

Compact and Modular: Saves panel space and simplifies installation.

-

Wide Environmental Tolerance: Functions in extreme temperature and humidity conditions.

-

Field Upgradeable: Firmware can be updated without removing the module.

-

Certified Safety: Complies with CE and RoHS industrial standards.

FAQ

1. How does the EB401 ensure communication reliability in redundant setups?

It uses dual ER bus channels for automatic failover if one path fails.

2. Can EB401 handle high-speed real-time data?

Yes, it supports high-speed synchronous communication for real-time process control.

3. How many slave devices can EB401 manage?

It supports multiple ER bus slaves; the exact number depends on the system design.

4. Does EB401 allow online module replacement?

Yes, it supports hot-swapping without system shutdown.

5. What diagnostic features are included?

It offers self-diagnostics, error detection, and LED status indicators for quick fault isolation.

6. Is EB401 compatible with Yokogawa CENTUM VP?

Yes, it is fully integrated with CENTUM VP and other Yokogawa DCS platforms.

7. Can the firmware be updated in the field?

Yes, the module supports online firmware updates through Yokogawa tools.

8. How does EB401 resist electromagnetic interference?

It is EMI-shielded and complies with IEC standards for EMC protection.

9. What is the recommended power supply tolerance?

24 V DC ±10% is required for optimal performance.

10. How does EB401 handle communication errors?

It uses error detection and correction protocols to ensure data integrity.

Yokogawa EB401 ER Bus Interface Master Module

Manufacturer:Yokogawa

Product Number:EB401

Product Type:ER Bus Interface Master Module

Origin:Japan

Dimensions:144.65 x 130 x 32.8 mm

Weight:0.3 kg

Views:82

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa EB401 ER Bus Interface Master Module is a key component within Yokogawa’s distributed control systems (DCS). It serves as the master interface for the ER Bus communication network, enabling high-speed, reliable data exchange between system controllers and remote I/O modules.

Designed for mission-critical industrial applications, EB401 supports redundancy, fault detection, and self-diagnostics to ensure uninterrupted communication. Its robust design makes it suitable for harsh environments, commonly seen in industries like oil & gas, power generation, and petrochemicals.

Product Specifications

| Parameter | Description |

|---|---|

| Model | EB401 |

| Function | ER Bus Interface Master Module |

| Communication Protocol | ER Bus |

| Data Transfer Mode | High-speed synchronous communication |

| Power Supply | 24 V DC (nominal) |

| Power Consumption | Approx. 6 W |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% to 95% RH (non-condensing) |

| Installation Method | Rack-mounted within System Rack |

| Compliance | CE, RoHS |

| Redundancy Support | Yes |

| Diagnostic Features | Self-diagnostic, Error Detection, LED Status |

| Dimensions (H × W × D) | 144.65 x 130 x 32.8 mm |

| Weight | 0.3 kg |

Applications

-

Distributed Control Systems (DCS): Ensures real-time communication between control units and remote I/O.

-

Process Automation: Provides high-speed, reliable data exchange for complex industrial processes.

-

Redundant Safety Systems: Maintains continuous operation in safety-critical environments.

-

Power Generation Plants: Optimizes control and monitoring for energy production facilities.

-

Oil & Gas Operations: Guarantees data reliability for upstream and downstream processes.

-

Petrochemical Industry: Handles communication in hazardous process conditions.

Product Advantages

-

High-Speed Communication: Supports synchronous data exchange with minimal latency.

-

Redundancy Design: Dual-channel ER bus ensures uninterrupted operation.

-

Compact and Modular: Saves panel space and simplifies installation.

-

Wide Environmental Tolerance: Functions in extreme temperature and humidity conditions.

-

Field Upgradeable: Firmware can be updated without removing the module.

-

Certified Safety: Complies with CE and RoHS industrial standards.

FAQ

1. How does the EB401 ensure communication reliability in redundant setups?

It uses dual ER bus channels for automatic failover if one path fails.

2. Can EB401 handle high-speed real-time data?

Yes, it supports high-speed synchronous communication for real-time process control.

3. How many slave devices can EB401 manage?

It supports multiple ER bus slaves; the exact number depends on the system design.

4. Does EB401 allow online module replacement?

Yes, it supports hot-swapping without system shutdown.

5. What diagnostic features are included?

It offers self-diagnostics, error detection, and LED status indicators for quick fault isolation.

6. Is EB401 compatible with Yokogawa CENTUM VP?

Yes, it is fully integrated with CENTUM VP and other Yokogawa DCS platforms.

7. Can the firmware be updated in the field?

Yes, the module supports online firmware updates through Yokogawa tools.

8. How does EB401 resist electromagnetic interference?

It is EMI-shielded and complies with IEC standards for EMC protection.

9. What is the recommended power supply tolerance?

24 V DC ±10% is required for optimal performance.

10. How does EB401 handle communication errors?

It uses error detection and correction protocols to ensure data integrity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...