Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

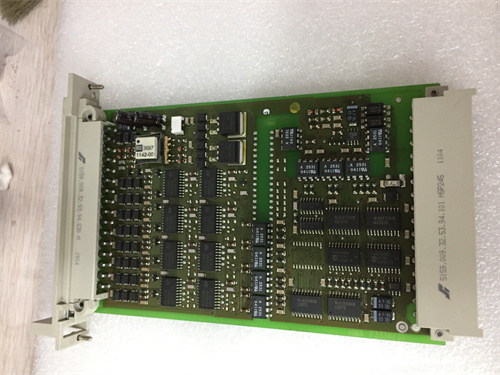

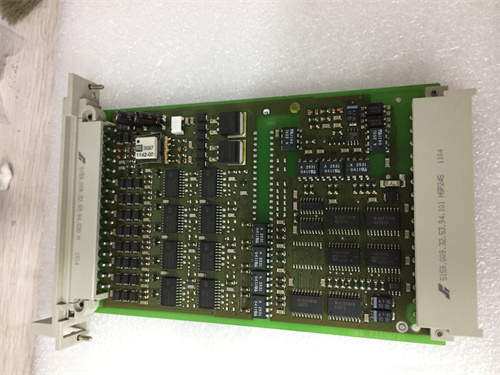

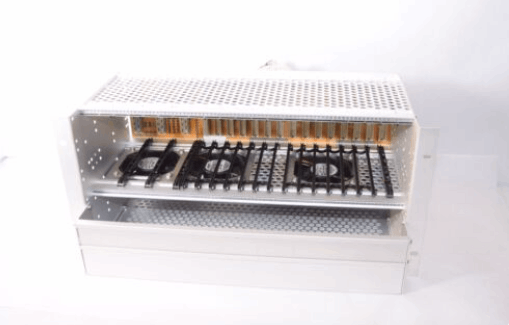

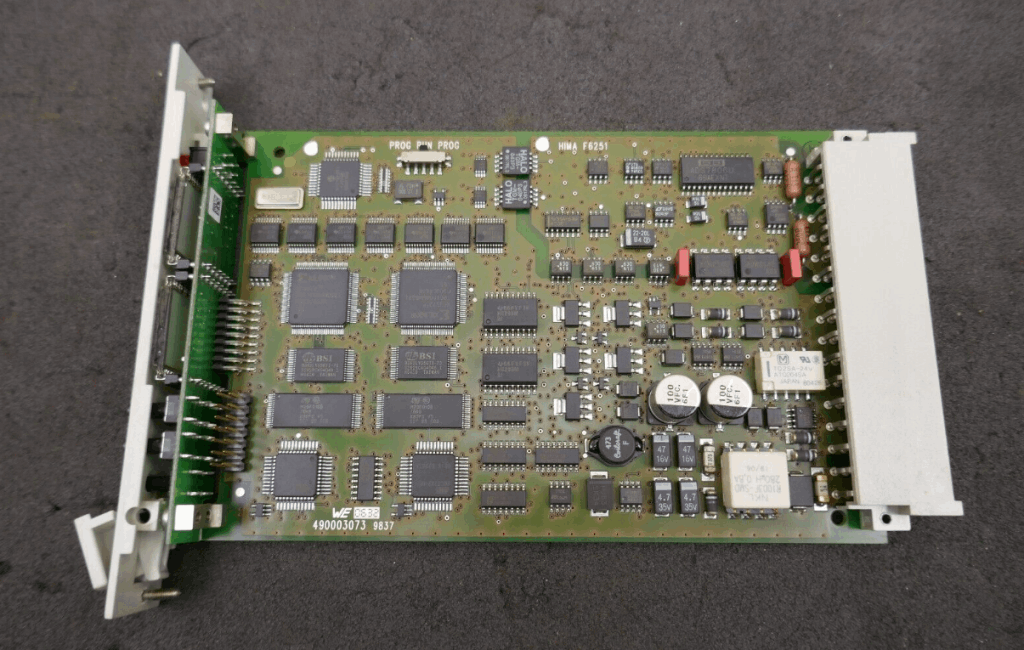

Hima H15Q-HS B5233-1 997105233 Central Rack System

Manufacturer:HIMA

Product Number:H15Q-HS B5233-1 997105233

Product Type:Central Rack System

Origin:Germany

Dimensions:248 x 222 mm

Weight:2.8 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

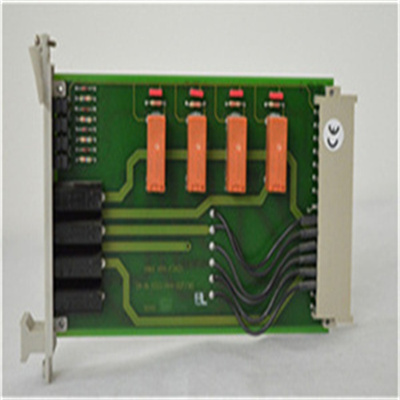

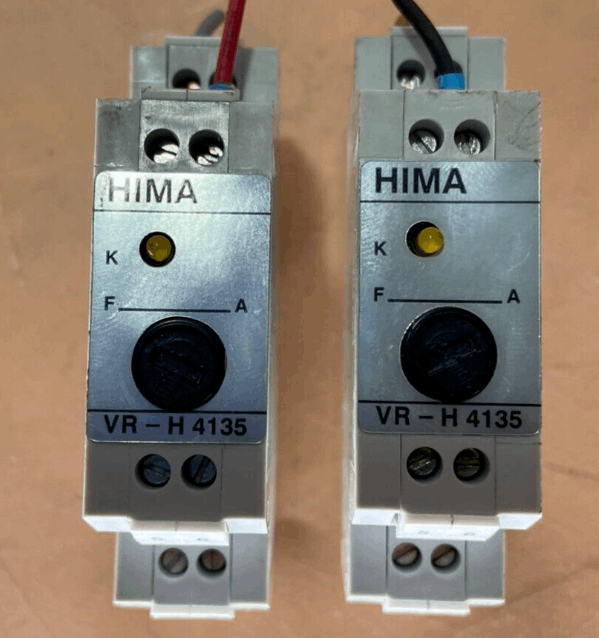

The HIMA H15Q-HS B5233-1 997105233 Central Rack System is a high-performance and safety-certified platform designed for HIMA’s H15Q-HS Safety Instrumented System (SIS). It provides centralized housing for processor modules, input/output modules, and communication gateways, serving as the backbone for safety-critical automation systems in industrial environments.

The central rack is engineered for maximum reliability and fault tolerance, supporting both redundant and simplex configurations. Its robust design ensures deterministic communication and power distribution to all connected modules, allowing continuous monitoring and control of industrial processes.

This rack system meets IEC 61508 SIL 3 and IEC 61511 standards, making it suitable for industries where high safety integrity and real-time processing are required, including oil & gas, petrochemical, power generation, and critical infrastructure sectors.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | HIMA H15Q-HS B5233-1 997105233 |

| Type | Central Rack System |

| Function | Centralized housing, power distribution, and communication hub for HIMA modules |

| Compatible Modules | Processor modules, digital/analog I/O modules, gateway modules |

| Power Supply | 24 VDC redundant input, system managed |

| Communication | Redundant backplane bus, supports deterministic module communication |

| Diagnostics | Power status, bus activity, module health monitoring via LEDs |

| Cooling | Passive and fan-assisted airflow with module ventilation |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -20 °C to +70 °C |

| Humidity | 10–95% RH, non-condensing |

| Safety Certification | IEC 61508 SIL 3, IEC 61511 |

| Mounting | 19-inch rack or panel-mounted installation |

| Dimensions | 248 x 222 mm |

| Weight | 2.8 kg |

Product Applications

The H15Q-HS B5233-1 997105233 Central Rack System is deployed in environments requiring highly reliable safety systems:

-

Oil & Gas – Integration of emergency shutdown systems, fire & gas detection, and pressure/flow interlocks.

-

Petrochemical Plants – Supports centralized control for chemical reactors, process vessels, and pipeline monitoring.

-

Power Generation – Houses modules for turbine, generator, and boiler safety logic.

-

Pipeline Systems – Centralizes modules controlling pressure, valve, and flow interlocks.

-

Industrial Automation – Provides deterministic execution for process safety and control.

-

Redundant Safety Systems – Enables duplex or triplex module arrangements for fault-tolerant operation.

Product Advantages

-

Centralized System Architecture – Consolidates all safety-critical modules into a single robust rack.

-

Redundancy Support – Enables redundant power and module configurations for uninterrupted safety operation.

-

Modular Design – Simplifies maintenance and replacement of individual modules without affecting overall system operation.

-

Comprehensive Diagnostics – Real-time monitoring of power, communication bus, and module health for proactive maintenance.

-

Safety Compliance – Certified to IEC 61508 SIL 3 and IEC 61511, suitable for mission-critical applications.

-

Flexible Installation – Compatible with standard 19-inch racks and optional panel mounting.

-

Industrial Durability – Resistant to vibration, temperature fluctuations, and electrical interference.

-

Scalable Expansion – Additional modules can be integrated to meet evolving system requirements.

FAQ

-

What is the primary function of the H15Q-HS B5233-1 997105233?

It provides centralized housing, power distribution, and communication for HIMA SIS modules.

-

Does the central rack support redundant systems?

Yes, it supports redundant power inputs and redundant module configurations.

-

How does the rack communicate with installed modules?

It uses a redundant backplane bus for deterministic module communication.

-

Is the system compatible with 19-inch racks?

Yes, it can be installed in standard 19-inch racks or optionally panel-mounted.

-

What type of power supply is required?

It requires 24 VDC redundant power input from industrial-grade power sources.

-

Are there diagnostic indicators on the rack?

Yes, it provides LEDs for power, bus activity, and module health monitoring.

-

Can the rack be used in SIL 3 applications?

Yes, it is certified according to IEC 61508 SIL 3 and IEC 61511 standards.

-

Does the rack support multiple module types simultaneously?

Yes, it can integrate processor, digital/analog I/O, and gateway modules together.

-

Is cooling required for the rack system?

Yes, it uses passive and fan-assisted airflow to maintain safe operating temperatures.

-

Can the system be expanded in the future?

Yes, additional modules can be added, and redundant configurations can be extended as required.

Hima H15Q-HS B5233-1 997105233 Central Rack System

Manufacturer:HIMA

Product Number:H15Q-HS B5233-1 997105233

Product Type:Central Rack System

Origin:Germany

Dimensions:248 x 222 mm

Weight:2.8 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA H15Q-HS B5233-1 997105233 Central Rack System is a high-performance and safety-certified platform designed for HIMA’s H15Q-HS Safety Instrumented System (SIS). It provides centralized housing for processor modules, input/output modules, and communication gateways, serving as the backbone for safety-critical automation systems in industrial environments.

The central rack is engineered for maximum reliability and fault tolerance, supporting both redundant and simplex configurations. Its robust design ensures deterministic communication and power distribution to all connected modules, allowing continuous monitoring and control of industrial processes.

This rack system meets IEC 61508 SIL 3 and IEC 61511 standards, making it suitable for industries where high safety integrity and real-time processing are required, including oil & gas, petrochemical, power generation, and critical infrastructure sectors.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | HIMA H15Q-HS B5233-1 997105233 |

| Type | Central Rack System |

| Function | Centralized housing, power distribution, and communication hub for HIMA modules |

| Compatible Modules | Processor modules, digital/analog I/O modules, gateway modules |

| Power Supply | 24 VDC redundant input, system managed |

| Communication | Redundant backplane bus, supports deterministic module communication |

| Diagnostics | Power status, bus activity, module health monitoring via LEDs |

| Cooling | Passive and fan-assisted airflow with module ventilation |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -20 °C to +70 °C |

| Humidity | 10–95% RH, non-condensing |

| Safety Certification | IEC 61508 SIL 3, IEC 61511 |

| Mounting | 19-inch rack or panel-mounted installation |

| Dimensions | 248 x 222 mm |

| Weight | 2.8 kg |

Product Applications

The H15Q-HS B5233-1 997105233 Central Rack System is deployed in environments requiring highly reliable safety systems:

-

Oil & Gas – Integration of emergency shutdown systems, fire & gas detection, and pressure/flow interlocks.

-

Petrochemical Plants – Supports centralized control for chemical reactors, process vessels, and pipeline monitoring.

-

Power Generation – Houses modules for turbine, generator, and boiler safety logic.

-

Pipeline Systems – Centralizes modules controlling pressure, valve, and flow interlocks.

-

Industrial Automation – Provides deterministic execution for process safety and control.

-

Redundant Safety Systems – Enables duplex or triplex module arrangements for fault-tolerant operation.

Product Advantages

-

Centralized System Architecture – Consolidates all safety-critical modules into a single robust rack.

-

Redundancy Support – Enables redundant power and module configurations for uninterrupted safety operation.

-

Modular Design – Simplifies maintenance and replacement of individual modules without affecting overall system operation.

-

Comprehensive Diagnostics – Real-time monitoring of power, communication bus, and module health for proactive maintenance.

-

Safety Compliance – Certified to IEC 61508 SIL 3 and IEC 61511, suitable for mission-critical applications.

-

Flexible Installation – Compatible with standard 19-inch racks and optional panel mounting.

-

Industrial Durability – Resistant to vibration, temperature fluctuations, and electrical interference.

-

Scalable Expansion – Additional modules can be integrated to meet evolving system requirements.

FAQ

-

What is the primary function of the H15Q-HS B5233-1 997105233?

It provides centralized housing, power distribution, and communication for HIMA SIS modules.

-

Does the central rack support redundant systems?

Yes, it supports redundant power inputs and redundant module configurations.

-

How does the rack communicate with installed modules?

It uses a redundant backplane bus for deterministic module communication.

-

Is the system compatible with 19-inch racks?

Yes, it can be installed in standard 19-inch racks or optionally panel-mounted.

-

What type of power supply is required?

It requires 24 VDC redundant power input from industrial-grade power sources.

-

Are there diagnostic indicators on the rack?

Yes, it provides LEDs for power, bus activity, and module health monitoring.

-

Can the rack be used in SIL 3 applications?

Yes, it is certified according to IEC 61508 SIL 3 and IEC 61511 standards.

-

Does the rack support multiple module types simultaneously?

Yes, it can integrate processor, digital/analog I/O, and gateway modules together.

-

Is cooling required for the rack system?

Yes, it uses passive and fan-assisted airflow to maintain safe operating temperatures.

-

Can the system be expanded in the future?

Yes, additional modules can be added, and redundant configurations can be extended as required.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...