Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

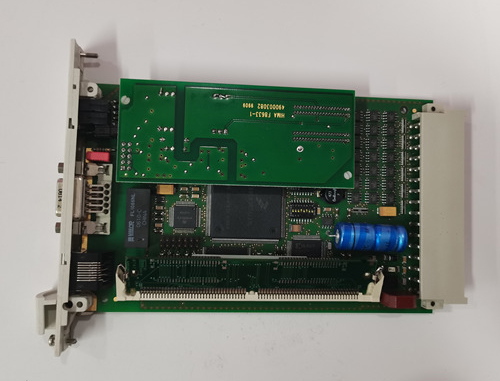

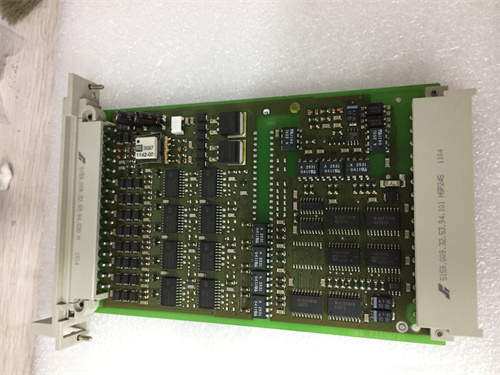

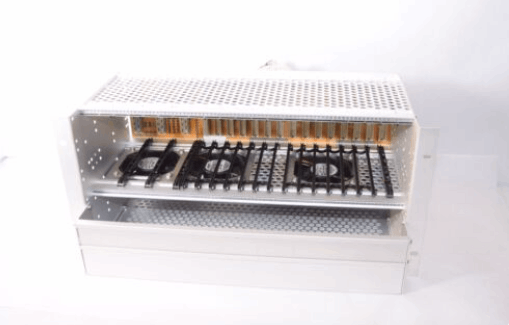

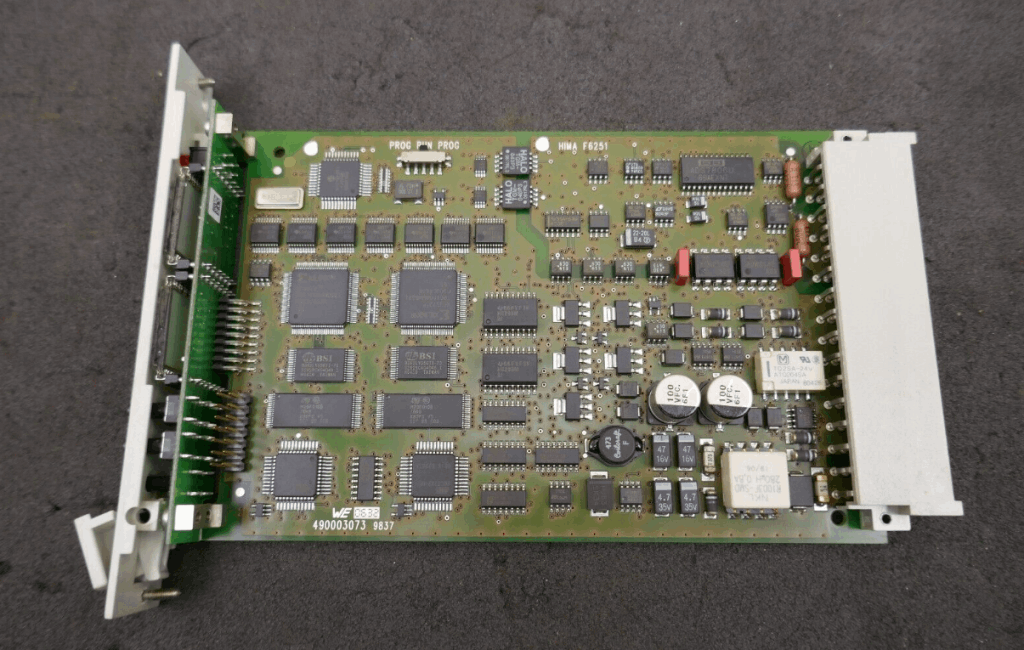

Hima F8650X 984865065 Central Module

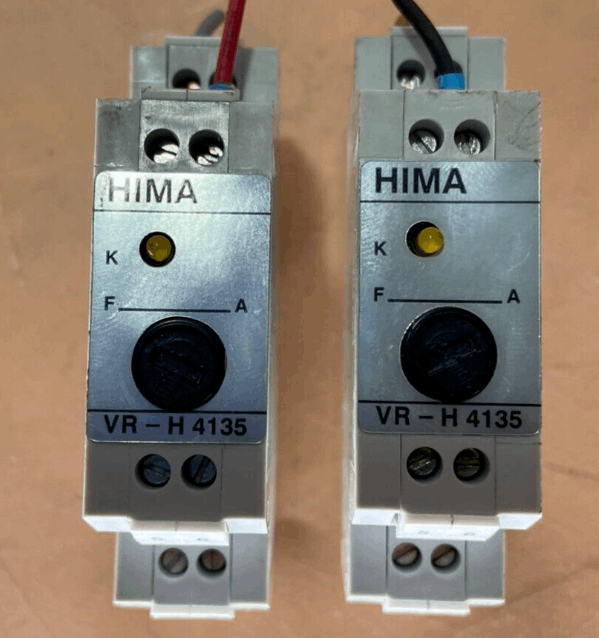

Manufacturer:HIMA

Product Number:F8650X 984865065

Product Type:Central Module

Origin:Germany

Dimensions:257 x 114 x 30 mm

Weight:1.5 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

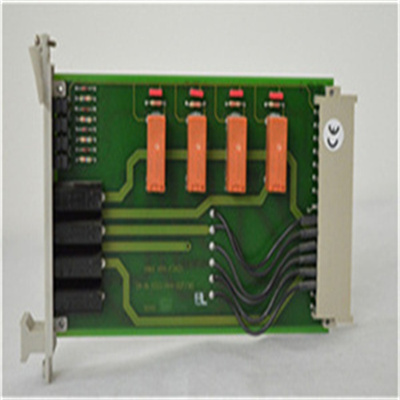

The HIMA F8650X Central Module (Part No. 984865065) is a high-availability, fail-safe processing unit specifically engineered for mission-critical safety applications in complex industrial environments. As an advanced evolution of the F8650E, the F8650X offers increased performance, enhanced diagnostics, and superior system integration for demanding applications in oil & gas, chemical plants, power generation, and rail systems.

Designed to operate in SIL 3-certified systems, the F8650X serves as the core control module in the HIMax safety system. It supports redundant and hot-swappable configurations, allowing system maintenance and upgrades without interrupting plant operations. Through its robust design and integrated fault tolerance, it guarantees system reliability, data integrity, and operational continuity in high-risk processes.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | F8650X Central Module |

| Part Number | 984865065 |

| System Compatibility | HIMax Safety System |

| Processor Architecture | Dual redundant 32-bit processors |

| Internal Memory | 128 MB RAM, 32 MB Flash memory |

| Diagnostics | Advanced internal self-checks, watchdogs, and error logging |

| Programming Software | SILworX |

| Communication Interfaces | Ethernet, RS485, RS232, HIMA system bus |

| Redundancy Support | Full support for CPU redundancy and hot-swap |

| Power Supply | 24 V DC (redundant supply input supported) |

| Operating Temperature Range | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Tolerance | 5% to 95%, non-condensing |

| Mounting Type | DIN rail mounting |

| Certifications | SIL 3 (IEC 61508), CE, TÜV, ATEX, EN 50156-2 |

| Dimensions (W x H x D) | 257 x 114 x 30 mm |

| Weight | 1.5 kg |

Product Applications

The HIMA F8650X is designed for complex applications requiring a high degree of fault tolerance and uninterrupted control. Its application areas span multiple industries where safety is non-negotiable:

-

Oil & Gas Production and Refining

Used in Emergency Shutdown Systems (ESD), Compressor Control, Burner Management, and Pipeline Monitoring.

-

Chemical and Petrochemical Processing

Ensures the integrity of exothermic reactions and pressure systems in SIL 3-rated environments.

-

Power Generation

Applied in turbine protection, boiler management, load shedding, and critical backup control circuits.

-

Railway Infrastructure

Trusted in interlocking systems, tunnel safety control, and train positioning management systems.

-

Pharmaceutical Industry

Guarantees the safety of sterile and hazardous production environments, supporting GxP compliance.

-

Water & Wastewater Facilities

Safeguards pumps, valves, and chemical dosing systems in municipal and industrial treatment plants.

Product Advantages

-

Advanced Redundancy

Full CPU redundancy allows seamless failover without any loss of functionality or system data.

-

Extended Diagnostics

Comprehensive internal health monitoring, diagnostic data logging, and predictive failure alerts.

-

Hot-Swap Capability

Modules can be replaced during live operations without interrupting the control process.

-

Certified Safety Integrity

Complies with international standards like IEC 61508 (SIL 3) and EN 50156-2, ensuring global acceptance.

-

Flexible Communication

Multiple standard interfaces make integration with SCADA, DCS, and third-party systems straightforward.

-

Robust Design for Harsh Environments

Resistant to vibration, temperature fluctuations, and electromagnetic interference (EMI), making it ideal for rugged field conditions.

-

Future-Proof Software Environment

Fully programmable using SILworX, with long-term lifecycle support and backward compatibility.

Frequently Asked Questions (FAQ)

-

What is the F8650X primarily used for?

It serves as the central CPU unit in HIMA HIMax safety systems, managing critical logic and system coordination.

-

Is it compatible with earlier HIMA systems?

The F8650X is backward compatible within HIMax environments and can be integrated into existing setups with minimal changes.

-

What safety certifications does the F8650X hold?

It is SIL 3 certified according to IEC 61508 and meets ATEX, CE, and TÜV requirements.

-

How is the F8650X programmed?

Programming is done using the SILworX development platform, tailored for safety logic development and verification.

-

Can the module be replaced without system shutdown?

Yes, it supports hot-swapping, enabling module replacement during full operation.

-

What are its redundancy features?

The CPU and power supplies can be fully redundant, ensuring zero downtime in the event of a failure.

-

What memory capacity does it offer?

It features 128 MB RAM and 32 MB Flash memory for logic and data storage.

-

Does the F8650X support remote diagnostics?

Yes, via Ethernet and HIMA communication protocols, remote diagnostics and monitoring are fully supported.

-

Is it suitable for explosive environments?

Yes, the unit is ATEX-certified and designed for use in Zone 2 hazardous locations.

-

What makes the F8650X different from the F8650E?

It offers higher performance, enhanced memory, improved diagnostics, and better support for modern protocols.

Hima F8650X 984865065 Central Module

Manufacturer:HIMA

Product Number:F8650X 984865065

Product Type:Central Module

Origin:Germany

Dimensions:257 x 114 x 30 mm

Weight:1.5 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F8650X Central Module (Part No. 984865065) is a high-availability, fail-safe processing unit specifically engineered for mission-critical safety applications in complex industrial environments. As an advanced evolution of the F8650E, the F8650X offers increased performance, enhanced diagnostics, and superior system integration for demanding applications in oil & gas, chemical plants, power generation, and rail systems.

Designed to operate in SIL 3-certified systems, the F8650X serves as the core control module in the HIMax safety system. It supports redundant and hot-swappable configurations, allowing system maintenance and upgrades without interrupting plant operations. Through its robust design and integrated fault tolerance, it guarantees system reliability, data integrity, and operational continuity in high-risk processes.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | F8650X Central Module |

| Part Number | 984865065 |

| System Compatibility | HIMax Safety System |

| Processor Architecture | Dual redundant 32-bit processors |

| Internal Memory | 128 MB RAM, 32 MB Flash memory |

| Diagnostics | Advanced internal self-checks, watchdogs, and error logging |

| Programming Software | SILworX |

| Communication Interfaces | Ethernet, RS485, RS232, HIMA system bus |

| Redundancy Support | Full support for CPU redundancy and hot-swap |

| Power Supply | 24 V DC (redundant supply input supported) |

| Operating Temperature Range | -20 °C to +60 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Tolerance | 5% to 95%, non-condensing |

| Mounting Type | DIN rail mounting |

| Certifications | SIL 3 (IEC 61508), CE, TÜV, ATEX, EN 50156-2 |

| Dimensions (W x H x D) | 257 x 114 x 30 mm |

| Weight | 1.5 kg |

Product Applications

The HIMA F8650X is designed for complex applications requiring a high degree of fault tolerance and uninterrupted control. Its application areas span multiple industries where safety is non-negotiable:

-

Oil & Gas Production and Refining

Used in Emergency Shutdown Systems (ESD), Compressor Control, Burner Management, and Pipeline Monitoring.

-

Chemical and Petrochemical Processing

Ensures the integrity of exothermic reactions and pressure systems in SIL 3-rated environments.

-

Power Generation

Applied in turbine protection, boiler management, load shedding, and critical backup control circuits.

-

Railway Infrastructure

Trusted in interlocking systems, tunnel safety control, and train positioning management systems.

-

Pharmaceutical Industry

Guarantees the safety of sterile and hazardous production environments, supporting GxP compliance.

-

Water & Wastewater Facilities

Safeguards pumps, valves, and chemical dosing systems in municipal and industrial treatment plants.

Product Advantages

-

Advanced Redundancy

Full CPU redundancy allows seamless failover without any loss of functionality or system data.

-

Extended Diagnostics

Comprehensive internal health monitoring, diagnostic data logging, and predictive failure alerts.

-

Hot-Swap Capability

Modules can be replaced during live operations without interrupting the control process.

-

Certified Safety Integrity

Complies with international standards like IEC 61508 (SIL 3) and EN 50156-2, ensuring global acceptance.

-

Flexible Communication

Multiple standard interfaces make integration with SCADA, DCS, and third-party systems straightforward.

-

Robust Design for Harsh Environments

Resistant to vibration, temperature fluctuations, and electromagnetic interference (EMI), making it ideal for rugged field conditions.

-

Future-Proof Software Environment

Fully programmable using SILworX, with long-term lifecycle support and backward compatibility.

Frequently Asked Questions (FAQ)

-

What is the F8650X primarily used for?

It serves as the central CPU unit in HIMA HIMax safety systems, managing critical logic and system coordination.

-

Is it compatible with earlier HIMA systems?

The F8650X is backward compatible within HIMax environments and can be integrated into existing setups with minimal changes.

-

What safety certifications does the F8650X hold?

It is SIL 3 certified according to IEC 61508 and meets ATEX, CE, and TÜV requirements.

-

How is the F8650X programmed?

Programming is done using the SILworX development platform, tailored for safety logic development and verification.

-

Can the module be replaced without system shutdown?

Yes, it supports hot-swapping, enabling module replacement during full operation.

-

What are its redundancy features?

The CPU and power supplies can be fully redundant, ensuring zero downtime in the event of a failure.

-

What memory capacity does it offer?

It features 128 MB RAM and 32 MB Flash memory for logic and data storage.

-

Does the F8650X support remote diagnostics?

Yes, via Ethernet and HIMA communication protocols, remote diagnostics and monitoring are fully supported.

-

Is it suitable for explosive environments?

Yes, the unit is ATEX-certified and designed for use in Zone 2 hazardous locations.

-

What makes the F8650X different from the F8650E?

It offers higher performance, enhanced memory, improved diagnostics, and better support for modern protocols.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...