Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

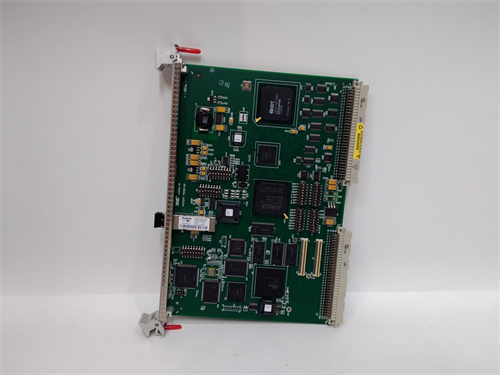

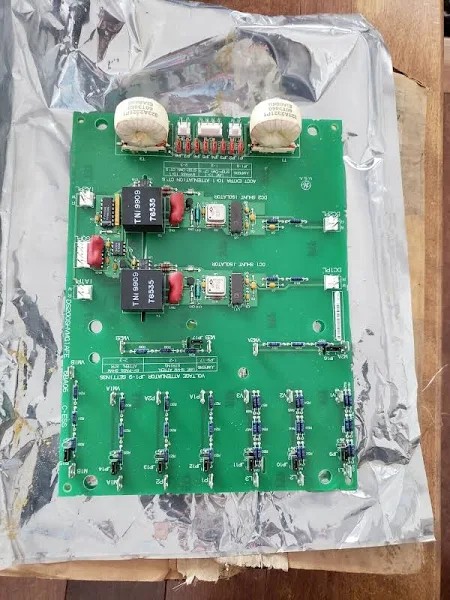

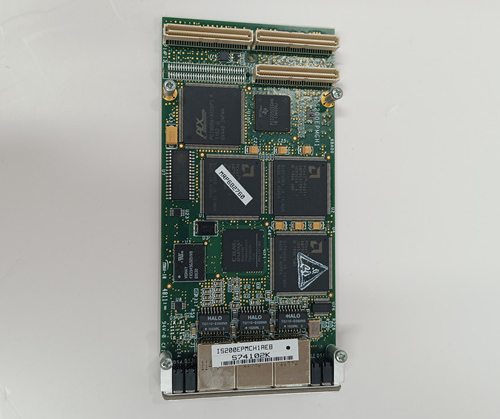

GE OC6000E Distributed Control System

Manufacturer:General Electric

Part Number:OC6000E

Product Type:Distributed Control System

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:241 x 194 x 152mm

Weight:6.2 lbs (2.8 kg)

Product Description

The GE OC 6000E Distributed Control System (DCS) is a comprehensive automation solution. It enhances operational efficiency, productivity, and reliability in industrial processes. By employing a distributed architecture with redundant components, the OC 6000E ensures continuous production. It also minimizes the impact of potential system failures.

Key Benefits of the OC 6000E

- Improved efficiency: Advanced control and optimization features optimize process performance and reduce energy consumption.

- Increased productivity: Streamlined operations and enhanced decision-making capabilities lead to higher production output.

- Enhanced reliability: Redundant system components and robust design minimize unplanned downtime and extend equipment life.

- Lower costs: Optimized operations, reduced maintenance, and increased uptime contribute to overall cost reduction.

Functions

The OC 6000E DCS offers various functionalities to support efficient plant operation:

Engineering Tools

Comprehensive software helps develop and manage control logic, graphics, databases, reports, and operator guides.

Operator Interface

User-friendly displays enable process monitoring, control, alarm management, and data visualization.

Data Management

Robust data logging capabilities record process data, alarms, and operator actions. This supports analysis and troubleshooting.

GE OC6000E Distributed Control System

Manufacturer:General Electric

Part Number:OC6000E

Product Type:Distributed Control System

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:241 x 194 x 152mm

Weight:6.2 lbs (2.8 kg)

Product Description

The GE OC 6000E Distributed Control System (DCS) is a comprehensive automation solution. It enhances operational efficiency, productivity, and reliability in industrial processes. By employing a distributed architecture with redundant components, the OC 6000E ensures continuous production. It also minimizes the impact of potential system failures.

Key Benefits of the OC 6000E

- Improved efficiency: Advanced control and optimization features optimize process performance and reduce energy consumption.

- Increased productivity: Streamlined operations and enhanced decision-making capabilities lead to higher production output.

- Enhanced reliability: Redundant system components and robust design minimize unplanned downtime and extend equipment life.

- Lower costs: Optimized operations, reduced maintenance, and increased uptime contribute to overall cost reduction.

Functions

The OC 6000E DCS offers various functionalities to support efficient plant operation:

Engineering Tools

Comprehensive software helps develop and manage control logic, graphics, databases, reports, and operator guides.

Operator Interface

User-friendly displays enable process monitoring, control, alarm management, and data visualization.

Data Management

Robust data logging capabilities record process data, alarms, and operator actions. This supports analysis and troubleshooting.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...