Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

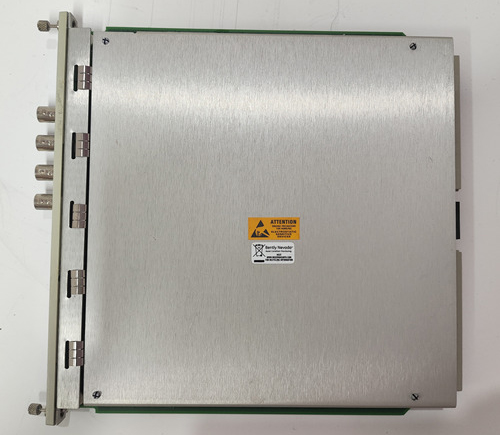

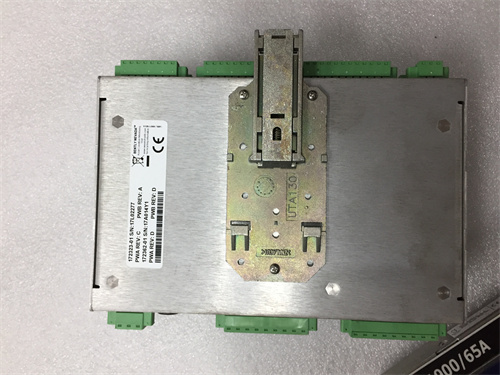

Bently Nevada 1900/65A-01-02-01-00-00 Universal Device Monitor

Manufacturer:Bently Nevada

Product Number:1900/65A-01-02-01-00-00

Product Type:Universal Device Monitor

Origin:USA

Dimensions:196.9 x 149.4 x 74.4mm

Weight:0.7kg

Views:91

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/65A-01-02-01-00-00 Universal Device Monitor (UDM) is a compact and reliable condition monitoring module designed for small to medium-sized rotating machinery. It delivers continuous monitoring of vibration, position, speed, and other critical parameters, providing early warning of equipment malfunctions to prevent costly downtime. The 1900/65A series is widely used in power generation, oil & gas, refining, and general industrial applications where dependable machine protection is essential.

Key Features

-

Continuous monitoring of critical machinery parameters

-

Flexible configuration for multiple measurement types

-

Compatible with Bently Nevada condition monitoring systems

-

Built-in alarm and relay functions for machinery protection

-

Compact and rugged design suitable for industrial environments

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 1900/65A-01-02-01-00-00 |

| Type | Universal Device Monitor |

| Channels | Up to 4 measurement channels |

| Supported Measurements | Vibration, position, speed, temperature |

| Power Supply | 24 V DC |

| Communication | Modbus RTU / Modbus TCP |

| Alarm Relays | 2 fully programmable |

| Operating Temperature | -20 °C to +65 °C |

| Dimensions | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.7 kg |

Industry Applications

-

Power generation (turbines, generators, motors)

-

Oil & gas (compressors, pumps, fans)

-

Petrochemical and refining industries

-

Mining and heavy machinery

-

Pulp & paper and manufacturing equipment

Advantages

-

Ensures continuous protection of critical assets

-

Reduces unexpected downtime and maintenance costs

-

Flexible configuration for diverse machinery setups

-

Proven reliability from Bently Nevada technology

-

Seamless integration with plant monitoring systems

Frequently Asked Questions (FAQ)

Q1: What is the function of the 1900/65A Universal Device Monitor?

It provides continuous monitoring and protection of small to medium rotating equipment.

Q2: How many channels does the 1900/65A-01-02-01-00-00 support?

It supports up to 4 measurement channels.

Q3: What measurements can it monitor?

It monitors vibration, position, speed, and temperature.

Q4: Does it include alarm relays?

Yes, it comes with 2 fully programmable alarm relays.

Q5: What communication protocols are available?

It supports Modbus RTU and Modbus TCP.

Q6: What is the typical power supply requirement?

It operates on 24 V DC.

Q7: Can this module integrate with a DCS or SCADA system?

Yes, it easily integrates via Modbus communication.

Q8: What is its operating temperature range?

It is designed to operate between -20 °C and +65 °C.

Q9: Where is the 1900/65A most commonly applied?

It is commonly used in power plants, oil & gas, and industrial manufacturing.

Q10: Is it compatible with other Bently Nevada systems?

Yes, it is designed for compatibility with Bently Nevada’s condition monitoring solutions.

Bently Nevada 1900/65A-01-02-01-00-00 Universal Device Monitor

Manufacturer:Bently Nevada

Product Number:1900/65A-01-02-01-00-00

Product Type:Universal Device Monitor

Origin:USA

Dimensions:196.9 x 149.4 x 74.4mm

Weight:0.7kg

Views:91

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/65A-01-02-01-00-00 Universal Device Monitor (UDM) is a compact and reliable condition monitoring module designed for small to medium-sized rotating machinery. It delivers continuous monitoring of vibration, position, speed, and other critical parameters, providing early warning of equipment malfunctions to prevent costly downtime. The 1900/65A series is widely used in power generation, oil & gas, refining, and general industrial applications where dependable machine protection is essential.

Key Features

-

Continuous monitoring of critical machinery parameters

-

Flexible configuration for multiple measurement types

-

Compatible with Bently Nevada condition monitoring systems

-

Built-in alarm and relay functions for machinery protection

-

Compact and rugged design suitable for industrial environments

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 1900/65A-01-02-01-00-00 |

| Type | Universal Device Monitor |

| Channels | Up to 4 measurement channels |

| Supported Measurements | Vibration, position, speed, temperature |

| Power Supply | 24 V DC |

| Communication | Modbus RTU / Modbus TCP |

| Alarm Relays | 2 fully programmable |

| Operating Temperature | -20 °C to +65 °C |

| Dimensions | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.7 kg |

Industry Applications

-

Power generation (turbines, generators, motors)

-

Oil & gas (compressors, pumps, fans)

-

Petrochemical and refining industries

-

Mining and heavy machinery

-

Pulp & paper and manufacturing equipment

Advantages

-

Ensures continuous protection of critical assets

-

Reduces unexpected downtime and maintenance costs

-

Flexible configuration for diverse machinery setups

-

Proven reliability from Bently Nevada technology

-

Seamless integration with plant monitoring systems

Frequently Asked Questions (FAQ)

Q1: What is the function of the 1900/65A Universal Device Monitor?

It provides continuous monitoring and protection of small to medium rotating equipment.

Q2: How many channels does the 1900/65A-01-02-01-00-00 support?

It supports up to 4 measurement channels.

Q3: What measurements can it monitor?

It monitors vibration, position, speed, and temperature.

Q4: Does it include alarm relays?

Yes, it comes with 2 fully programmable alarm relays.

Q5: What communication protocols are available?

It supports Modbus RTU and Modbus TCP.

Q6: What is the typical power supply requirement?

It operates on 24 V DC.

Q7: Can this module integrate with a DCS or SCADA system?

Yes, it easily integrates via Modbus communication.

Q8: What is its operating temperature range?

It is designed to operate between -20 °C and +65 °C.

Q9: Where is the 1900/65A most commonly applied?

It is commonly used in power plants, oil & gas, and industrial manufacturing.

Q10: Is it compatible with other Bently Nevada systems?

Yes, it is designed for compatibility with Bently Nevada’s condition monitoring solutions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...