Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

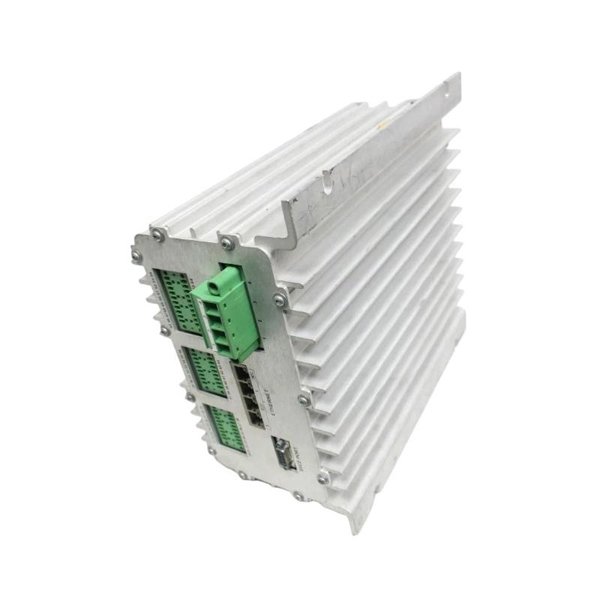

Woodward 8200-182 Turbine Driver

Manufacturer:Woodward

Product Number:8200-182

Product Type:Turbine Driver

Origin:USA

Dimensions:200 x 150 x 75 mm

Weight:0.8 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8200-182 Turbine Driver is a precision-engineered analog control module designed to provide stable and responsive positioning control for turbine valves in industrial power generation and mechanical drive applications. Serving as a fundamental component in Woodward’s turbine control systems, the 8200-182 delivers reliable hydraulic or electro-hydraulic actuator management for steam, gas, and hydro turbines.

This driver module converts control signals into precise valve positioning, ensuring optimal turbine performance, efficiency, and safety. It is engineered to meet the demands of harsh industrial environments, offering robust construction and consistent control characteristics across varying operating conditions.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 8200-182 |

| Type | Analog Turbine Driver Module |

| Control Method | Position control for valve actuation |

| Input Signal | 4-20 mA current input |

| Output Type | Hydraulic or electro-hydraulic actuator driver output |

| Operating Voltage | 24 VDC nominal, 18-32 VDC range |

| Control Range | Full stroke positioning with proportional control |

| Response Time | Typically less than 50 milliseconds |

| Operating Temperature | -20°C to +70°C |

| Mounting | Panel or chassis mounting |

| Dimensions (W x H x D) | 200 x 150 x 75 mm |

| Weight | 0.8 kg |

| Environmental Protection | IP20 (standard, with optional enclosure available) |

| Diagnostic Features | Position feedback monitoring, fault detection |

| Compliance Certifications | CE, UL, and other industrial standards |

Product Applications

-

Steam Turbine Control Systems

-

Gas Turbine Valve Actuation

-

Hydraulic Control of Mechanical Drives

-

Power Generation Plants

-

Oil and Gas Compressor Turbines

-

Industrial Process Turbine Controls

-

Cogeneration and Combined Cycle Systems

Product Advantages

-

Precise Position Control

Provides accurate valve positioning to optimize turbine efficiency and responsiveness.

-

Robust Industrial Design

Built for demanding environments with wide temperature tolerance and vibration resistance.

-

Fast Response Time

Ensures swift actuator movement for responsive turbine operation.

-

Compatibility

Works seamlessly with Woodward’s range of hydraulic and electro-hydraulic actuators.

-

Easy Installation and Integration

Compact design and standard mounting options simplify system integration.

-

Diagnostic Capabilities

Built-in position feedback and fault detection enable proactive maintenance.

-

Reliable Analog Control

Proven analog technology for consistent, repeatable control in critical applications.

FAQ

-

What input signals does the 8200-182 accept for position control?

It accepts a 4-20 mA current input signal representing the desired valve position.

-

Can the 8200-182 drive both hydraulic and electro-hydraulic actuators?

Yes, it is designed to interface with both actuator types for valve positioning.

-

What is the typical response time of this turbine driver?

The module responds within approximately 50 milliseconds.

-

Is the module suitable for use in harsh industrial environments?

Yes, it operates reliably across a temperature range of -20°C to +70°C and withstands vibration.

-

What are the mounting options for this driver module?

It supports panel and chassis mounting for flexible installation.

-

Does the 8200-182 provide position feedback for diagnostics?

Yes, it includes position feedback monitoring to aid in system diagnostics.

-

What is the power supply requirement for this module?

It requires a nominal 24 VDC supply within an 18-32 VDC operating range.

-

Does this driver support proportional valve control?

Yes, it provides proportional control of valve position across the full stroke.

-

Are there any certifications supporting the industrial use of this module?

The 8200-182 complies with CE, UL, and other relevant industrial certifications.

-

Can this module be integrated into existing Woodward turbine control systems?

Yes, it is designed to work seamlessly within Woodward’s turbine control architectures.

Woodward 8200-182 Turbine Driver

Manufacturer:Woodward

Product Number:8200-182

Product Type:Turbine Driver

Origin:USA

Dimensions:200 x 150 x 75 mm

Weight:0.8 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8200-182 Turbine Driver is a precision-engineered analog control module designed to provide stable and responsive positioning control for turbine valves in industrial power generation and mechanical drive applications. Serving as a fundamental component in Woodward’s turbine control systems, the 8200-182 delivers reliable hydraulic or electro-hydraulic actuator management for steam, gas, and hydro turbines.

This driver module converts control signals into precise valve positioning, ensuring optimal turbine performance, efficiency, and safety. It is engineered to meet the demands of harsh industrial environments, offering robust construction and consistent control characteristics across varying operating conditions.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 8200-182 |

| Type | Analog Turbine Driver Module |

| Control Method | Position control for valve actuation |

| Input Signal | 4-20 mA current input |

| Output Type | Hydraulic or electro-hydraulic actuator driver output |

| Operating Voltage | 24 VDC nominal, 18-32 VDC range |

| Control Range | Full stroke positioning with proportional control |

| Response Time | Typically less than 50 milliseconds |

| Operating Temperature | -20°C to +70°C |

| Mounting | Panel or chassis mounting |

| Dimensions (W x H x D) | 200 x 150 x 75 mm |

| Weight | 0.8 kg |

| Environmental Protection | IP20 (standard, with optional enclosure available) |

| Diagnostic Features | Position feedback monitoring, fault detection |

| Compliance Certifications | CE, UL, and other industrial standards |

Product Applications

-

Steam Turbine Control Systems

-

Gas Turbine Valve Actuation

-

Hydraulic Control of Mechanical Drives

-

Power Generation Plants

-

Oil and Gas Compressor Turbines

-

Industrial Process Turbine Controls

-

Cogeneration and Combined Cycle Systems

Product Advantages

-

Precise Position Control

Provides accurate valve positioning to optimize turbine efficiency and responsiveness.

-

Robust Industrial Design

Built for demanding environments with wide temperature tolerance and vibration resistance.

-

Fast Response Time

Ensures swift actuator movement for responsive turbine operation.

-

Compatibility

Works seamlessly with Woodward’s range of hydraulic and electro-hydraulic actuators.

-

Easy Installation and Integration

Compact design and standard mounting options simplify system integration.

-

Diagnostic Capabilities

Built-in position feedback and fault detection enable proactive maintenance.

-

Reliable Analog Control

Proven analog technology for consistent, repeatable control in critical applications.

FAQ

-

What input signals does the 8200-182 accept for position control?

It accepts a 4-20 mA current input signal representing the desired valve position.

-

Can the 8200-182 drive both hydraulic and electro-hydraulic actuators?

Yes, it is designed to interface with both actuator types for valve positioning.

-

What is the typical response time of this turbine driver?

The module responds within approximately 50 milliseconds.

-

Is the module suitable for use in harsh industrial environments?

Yes, it operates reliably across a temperature range of -20°C to +70°C and withstands vibration.

-

What are the mounting options for this driver module?

It supports panel and chassis mounting for flexible installation.

-

Does the 8200-182 provide position feedback for diagnostics?

Yes, it includes position feedback monitoring to aid in system diagnostics.

-

What is the power supply requirement for this module?

It requires a nominal 24 VDC supply within an 18-32 VDC operating range.

-

Does this driver support proportional valve control?

Yes, it provides proportional control of valve position across the full stroke.

-

Are there any certifications supporting the industrial use of this module?

The 8200-182 complies with CE, UL, and other relevant industrial certifications.

-

Can this module be integrated into existing Woodward turbine control systems?

Yes, it is designed to work seamlessly within Woodward’s turbine control architectures.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...