Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

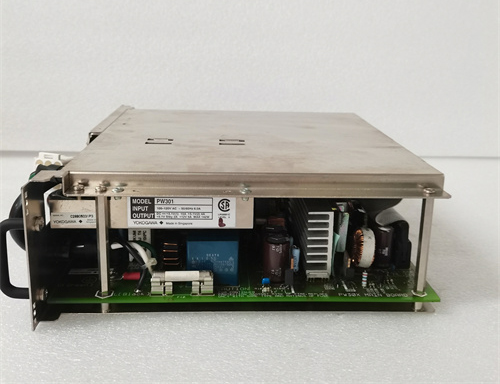

Yokogawa ALP111 Communication Module

Manufacturer:Yokogawa

Product Number:ALP111

Product Type:Communication Module

Origin:Japan

Dimensions:130 x 129.5 x 32.8 mm

Weight:0.3 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ALP111 Communication Module is a high-performance communication interface designed to connect control systems to remote I/O networks via PROFIBUS-DP. It acts as a key communication bridge in distributed control environments, enabling seamless and deterministic data transfer between Yokogawa’s CENTUM VP or CENTUM CS 3000 systems and field devices that support the PROFIBUS-DP protocol.

The ALP111 enhances automation flexibility by integrating third-party field instruments, valves, actuators, and sensors into the centralized control environment. It is especially valuable in large-scale plants requiring interoperability, reduced wiring complexity, real-time control, and efficient maintenance strategies. As part of Yokogawa’s Field Control Station (FCS) communication architecture, it ensures high availability, diagnostics visibility, and excellent performance in mission-critical industrial applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | ALP111 |

| Manufacturer | Yokogawa Electric Corporation |

| Communication Protocol | PROFIBUS-DP (DP-V0 / DP-V1 compliant) |

| Baud Rate | 9.6 kbps to 12 Mbps |

| Max Devices per Channel | Up to 32 (without repeater) |

| Number of Channels | 1 PROFIBUS-DP channel |

| Power Supply | Supplied via the control system rack (24 VDC nominal) |

| Interface Connector | D-sub 9-pin or terminal block (depending on system config) |

| Functionality | Master communication with DP slaves (field devices) |

| Redundancy Support | Yes (Hot standby module configuration supported) |

| Configuration Tool | Yokogawa PRM / Engineering Tool / FDT/DTM integration |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting | Rack-mounted in Field Control Station |

| Dimensions (H × W × D) | 130 x 129.5 x 32.8 mm |

| Weight | 0.3 kg |

| System Compatibility | CENTUM VP, CENTUM CS 3000 |

| Compliance Standards | IEC 61158-2, PROFIBUS standard |

Applications

The ALP111 is widely applied across various industries that rely on PROFIBUS-DP for field communication. Common applications include:

-

Oil & Gas

Integration of PROFIBUS-compatible valve positioners and flow meters into the central DCS for precise process control.

-

Chemical & Petrochemical

Interfacing multiple intelligent field devices in hazardous zones with full diagnostics and control access.

-

Power Generation

Communication with field I/O, sensors, and actuator networks for turbine and boiler management.

-

Pharmaceuticals

Enabling validated and traceable communications between DCS and manufacturing field equipment.

-

Food & Beverage

Ensures fast, consistent, and synchronized control across production lines with PROFIBUS-DP compatibility.

-

Water Treatment Plants

Offers seamless remote communication with distributed valve actuators and monitoring devices.

Key Advantages

-

Reliable PROFIBUS Master Functionality

As a PROFIBUS-DP master, the ALP111 effectively controls a network of intelligent field devices in real-time.

-

High Interoperability

Enables integration of third-party PROFIBUS-DP devices into Yokogawa systems, enhancing flexibility.

-

Diagnostics and Monitoring

Advanced diagnostic functions for quick fault detection and system status evaluation.

-

Redundancy Ready

Supports module redundancy to improve system availability in critical applications.

-

Space-Efficient Installation

Compact design fits into standard Yokogawa racks, reducing panel size and simplifying maintenance.

-

Seamless Engineering Tool Integration

Easily configured using Yokogawa engineering tools or device-specific DTM software.

Frequently Asked Questions (FAQ)

-

What is the purpose of the ALP111 module?

It facilitates communication between Yokogawa control systems and field devices using the PROFIBUS-DP protocol.

-

Can the ALP111 module control multiple PROFIBUS devices?

Yes, it can act as a master to control up to 32 devices directly per segment.

-

Is the ALP111 suitable for redundant configurations?

Yes, it supports hot standby redundancy to ensure uninterrupted communication.

-

Which systems are compatible with ALP111?

It is compatible with Yokogawa’s CENTUM VP and CENTUM CS 3000 control systems.

-

Does the module support diagnostics?

Yes, it provides diagnostics on PROFIBUS communication status and device-level health.

-

What is the communication speed supported?

It supports PROFIBUS speeds ranging from 9.6 kbps to 12 Mbps.

-

How is the module powered?

It receives power from the control system rack (typically 24 VDC).

-

Is the ALP111 compatible with non-Yokogawa field devices?

Yes, as long as they are PROFIBUS-DP compliant.

-

What configuration tools are required?

Yokogawa Engineering Tools or PRM software, with optional FDT/DTM integration.

-

Can it be mounted on a DIN rail?

No, it is designed for rack-mounting in a Yokogawa Field Control Station.

Yokogawa ALP111 Communication Module

Manufacturer:Yokogawa

Product Number:ALP111

Product Type:Communication Module

Origin:Japan

Dimensions:130 x 129.5 x 32.8 mm

Weight:0.3 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ALP111 Communication Module is a high-performance communication interface designed to connect control systems to remote I/O networks via PROFIBUS-DP. It acts as a key communication bridge in distributed control environments, enabling seamless and deterministic data transfer between Yokogawa’s CENTUM VP or CENTUM CS 3000 systems and field devices that support the PROFIBUS-DP protocol.

The ALP111 enhances automation flexibility by integrating third-party field instruments, valves, actuators, and sensors into the centralized control environment. It is especially valuable in large-scale plants requiring interoperability, reduced wiring complexity, real-time control, and efficient maintenance strategies. As part of Yokogawa’s Field Control Station (FCS) communication architecture, it ensures high availability, diagnostics visibility, and excellent performance in mission-critical industrial applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | ALP111 |

| Manufacturer | Yokogawa Electric Corporation |

| Communication Protocol | PROFIBUS-DP (DP-V0 / DP-V1 compliant) |

| Baud Rate | 9.6 kbps to 12 Mbps |

| Max Devices per Channel | Up to 32 (without repeater) |

| Number of Channels | 1 PROFIBUS-DP channel |

| Power Supply | Supplied via the control system rack (24 VDC nominal) |

| Interface Connector | D-sub 9-pin or terminal block (depending on system config) |

| Functionality | Master communication with DP slaves (field devices) |

| Redundancy Support | Yes (Hot standby module configuration supported) |

| Configuration Tool | Yokogawa PRM / Engineering Tool / FDT/DTM integration |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting | Rack-mounted in Field Control Station |

| Dimensions (H × W × D) | 130 x 129.5 x 32.8 mm |

| Weight | 0.3 kg |

| System Compatibility | CENTUM VP, CENTUM CS 3000 |

| Compliance Standards | IEC 61158-2, PROFIBUS standard |

Applications

The ALP111 is widely applied across various industries that rely on PROFIBUS-DP for field communication. Common applications include:

-

Oil & Gas

Integration of PROFIBUS-compatible valve positioners and flow meters into the central DCS for precise process control.

-

Chemical & Petrochemical

Interfacing multiple intelligent field devices in hazardous zones with full diagnostics and control access.

-

Power Generation

Communication with field I/O, sensors, and actuator networks for turbine and boiler management.

-

Pharmaceuticals

Enabling validated and traceable communications between DCS and manufacturing field equipment.

-

Food & Beverage

Ensures fast, consistent, and synchronized control across production lines with PROFIBUS-DP compatibility.

-

Water Treatment Plants

Offers seamless remote communication with distributed valve actuators and monitoring devices.

Key Advantages

-

Reliable PROFIBUS Master Functionality

As a PROFIBUS-DP master, the ALP111 effectively controls a network of intelligent field devices in real-time.

-

High Interoperability

Enables integration of third-party PROFIBUS-DP devices into Yokogawa systems, enhancing flexibility.

-

Diagnostics and Monitoring

Advanced diagnostic functions for quick fault detection and system status evaluation.

-

Redundancy Ready

Supports module redundancy to improve system availability in critical applications.

-

Space-Efficient Installation

Compact design fits into standard Yokogawa racks, reducing panel size and simplifying maintenance.

-

Seamless Engineering Tool Integration

Easily configured using Yokogawa engineering tools or device-specific DTM software.

Frequently Asked Questions (FAQ)

-

What is the purpose of the ALP111 module?

It facilitates communication between Yokogawa control systems and field devices using the PROFIBUS-DP protocol.

-

Can the ALP111 module control multiple PROFIBUS devices?

Yes, it can act as a master to control up to 32 devices directly per segment.

-

Is the ALP111 suitable for redundant configurations?

Yes, it supports hot standby redundancy to ensure uninterrupted communication.

-

Which systems are compatible with ALP111?

It is compatible with Yokogawa’s CENTUM VP and CENTUM CS 3000 control systems.

-

Does the module support diagnostics?

Yes, it provides diagnostics on PROFIBUS communication status and device-level health.

-

What is the communication speed supported?

It supports PROFIBUS speeds ranging from 9.6 kbps to 12 Mbps.

-

How is the module powered?

It receives power from the control system rack (typically 24 VDC).

-

Is the ALP111 compatible with non-Yokogawa field devices?

Yes, as long as they are PROFIBUS-DP compliant.

-

What configuration tools are required?

Yokogawa Engineering Tools or PRM software, with optional FDT/DTM integration.

-

Can it be mounted on a DIN rail?

No, it is designed for rack-mounting in a Yokogawa Field Control Station.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...