Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

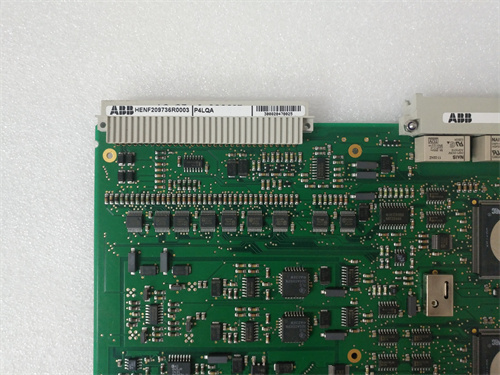

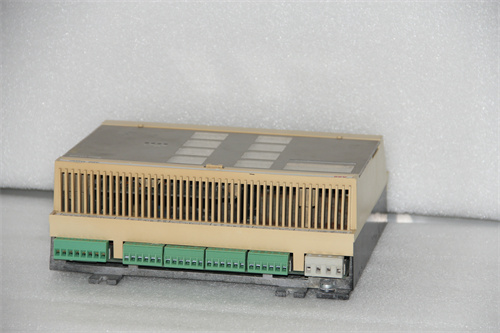

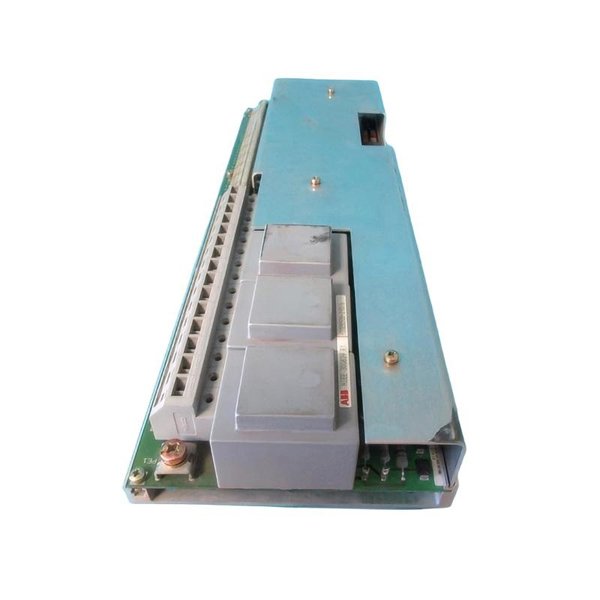

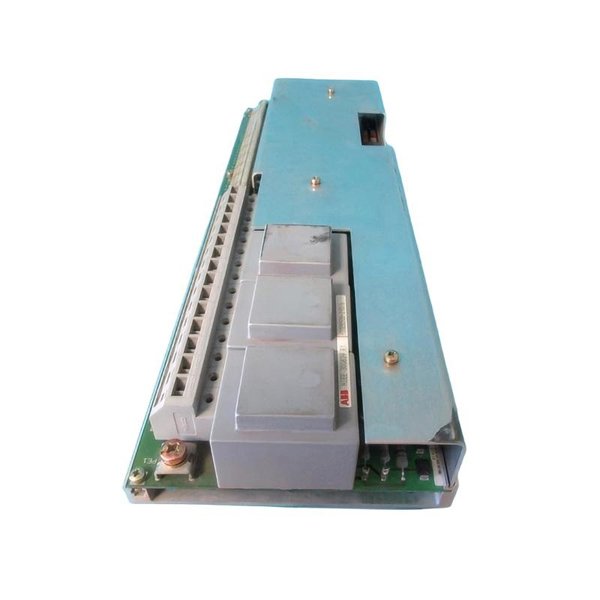

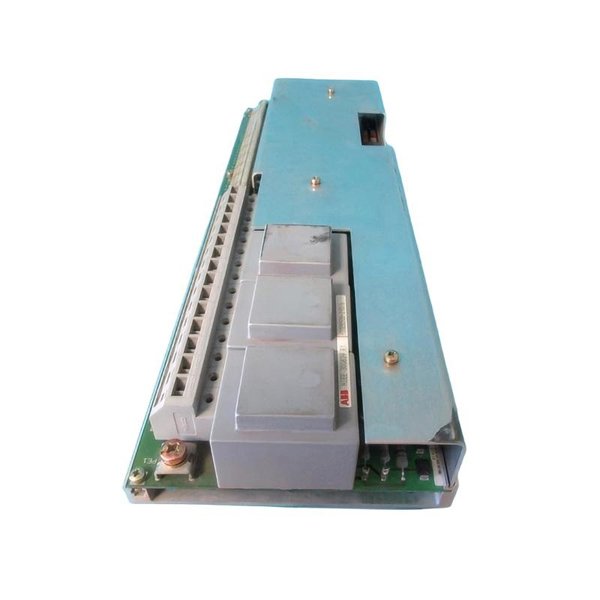

ABB UA C346 AE01 HIEE300831R0001 Control Module

Manufacturer:ABB

Product Number:UA C346 AE01 HIEE300831R0001

Product Type:Control Module

Origin:Sweden

Dimensions:180 × 160 × 40 mm

Weight:0.85 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB UA C346 AE01 (Part Number: HIEE300831R0001) is a high-performance control module designed for integration into ABB’s advanced process automation and power management systems. This module functions as a critical interface for logic control, analog/digital I/O processing, communication routing, and real-time diagnostic execution in distributed control environments.

Belonging to the ABB Symphony, Advant, or industrial controller families, the UA C346 AE01 is engineered for precision, reliability, and flexibility in high-demand industrial applications. It incorporates robust embedded processing capabilities, memory management, and multiple communication interfaces to support seamless operation in complex control infrastructures.

This module is particularly favored in industries requiring high availability, deterministic control logic, and rapid fault diagnostics—such as energy generation, metals, chemicals, and water treatment systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | UA C346 AE01 |

| Part Number | HIEE300831R0001 |

| Function | Control module for logic processing and I/O interfacing |

| Processor Type | 32-bit RISC industrial processor |

| Clock Speed | ~50 MHz |

| Memory (RAM) | 2 MB SRAM |

| Flash Memory | 4 MB EEPROM or Flash |

| Digital I/O Support | Yes (configurable per application) |

| Analog Signal Handling | Via separate modules through backplane communication |

| Communication Interfaces | RS-232 / RS-485 / CAN / Ethernet (via system) |

| Redundancy Support | Supported (hot-standby architecture enabled) |

| Protocol Support | Modbus, Profibus, TCP/IP, proprietary ABB bus |

| Diagnostic Features | Fault detection, watchdog timer, LED indicators |

| Power Supply | 24 VDC nominal (range 18–36 VDC) |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% – 95% non-condensing |

| Cooling Method | Passive convection |

| Mounting Type | Rack/backplane mounted |

| Dimensions (W × H × D) | 180 × 160 × 40 mm |

| Weight | 0.85 kg |

| Certifications | CE, RoHS, IEC 61131-2, UL compliant |

Applications

The ABB UA C346 AE01 is used across several critical industries where real-time, deterministic control logic and robust communication handling are vital. Key application areas include:

-

Thermal and Hydroelectric Power Plants: Controls auxiliary systems, valve logic, and turbine sequencing.

-

Industrial Automation (DCS/PLC systems): Executes process logic, manages signal conditioning, and supervises alarms.

-

Metallurgy and Rolling Mills: Synchronizes motor drives and monitors critical parameters in harsh environments.

-

Chemical Processing Plants: Manages batch control sequences, safety interlocks, and analog sensor loops.

-

Water & Wastewater Treatment: Controls flow, pH adjustment, and filtration sequencing.

-

Oil & Gas Terminals: Monitors pipeline pressures, leak detection, and SCADA integration.

Product Advantages

-

Integrated Real-Time Processing: Enables deterministic control logic execution without delay or interference.

-

Versatile Communication Compatibility: Interfaces with multiple protocols to adapt to varied automation networks.

-

Fault Tolerance and Redundancy: Supports redundant configuration for high-availability applications.

-

Advanced Diagnostics: Self-diagnosis and watchdog capabilities minimize downtime in critical systems.

-

Easy System Integration: Seamlessly interfaces with ABB Symphony and Advant systems via standardized backplanes.

-

Long-Term Software Support: Ensures sustainability through compatibility with ABB system tools and engineering suites.

-

Modular Expansion: Supports additional I/O, communication, and functional modules through backplane slots.

-

Industrial-Grade Durability: Operates reliably under high temperature, humidity, and EMC stress conditions.

-

Low Maintenance Footprint: Passive cooling and non-moving parts contribute to system longevity.

-

Custom Logic Support: Allows plant-specific ladder logic or function block configurations via ABB tools.

FAQs

-

Does the UA C346 AE01 support distributed I/O via fieldbus?

Yes, it supports distributed I/O using protocols such as Profibus and Modbus RTU over RS-485.

-

Can this module handle time-critical sequencing applications?

Absolutely. The module is built for deterministic response and supports scan cycle optimization.

-

What are the methods available for firmware upgrade on this unit?

Firmware can be updated via a serial port or internal backplane using ABB configuration tools.

-

Does it support hardware watchdog mechanisms?

Yes, it has an integrated hardware watchdog for fault recovery and fail-safe operation.

-

Can the module operate in a redundant control configuration?

Yes, it supports hot-standby redundancy with automatic switchover capabilities.

-

What is the I/O refresh rate or scan cycle time?

The scan cycle is typically under 5 ms, depending on application load and I/O count.

-

How does the module handle communication interruptions?

Communication errors are logged and trigger alarms. Logic can be configured for fail-safe action.

-

Are event logs and system diagnostics accessible remotely?

Yes, via ABB engineering tools or remote terminal interface using supported protocols.

-

Is the module programmable using standard IEC 61131-3 languages?

It supports ABB’s proprietary engineering environment, which aligns with IEC 61131 logic formats.

-

What isolation techniques are used for signal integrity?

Optical isolation and transformer-based separation are applied between control and field signal paths.

ABB UA C346 AE01 HIEE300831R0001 Control Module

Manufacturer:ABB

Product Number:UA C346 AE01 HIEE300831R0001

Product Type:Control Module

Origin:Sweden

Dimensions:180 × 160 × 40 mm

Weight:0.85 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB UA C346 AE01 (Part Number: HIEE300831R0001) is a high-performance control module designed for integration into ABB’s advanced process automation and power management systems. This module functions as a critical interface for logic control, analog/digital I/O processing, communication routing, and real-time diagnostic execution in distributed control environments.

Belonging to the ABB Symphony, Advant, or industrial controller families, the UA C346 AE01 is engineered for precision, reliability, and flexibility in high-demand industrial applications. It incorporates robust embedded processing capabilities, memory management, and multiple communication interfaces to support seamless operation in complex control infrastructures.

This module is particularly favored in industries requiring high availability, deterministic control logic, and rapid fault diagnostics—such as energy generation, metals, chemicals, and water treatment systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | UA C346 AE01 |

| Part Number | HIEE300831R0001 |

| Function | Control module for logic processing and I/O interfacing |

| Processor Type | 32-bit RISC industrial processor |

| Clock Speed | ~50 MHz |

| Memory (RAM) | 2 MB SRAM |

| Flash Memory | 4 MB EEPROM or Flash |

| Digital I/O Support | Yes (configurable per application) |

| Analog Signal Handling | Via separate modules through backplane communication |

| Communication Interfaces | RS-232 / RS-485 / CAN / Ethernet (via system) |

| Redundancy Support | Supported (hot-standby architecture enabled) |

| Protocol Support | Modbus, Profibus, TCP/IP, proprietary ABB bus |

| Diagnostic Features | Fault detection, watchdog timer, LED indicators |

| Power Supply | 24 VDC nominal (range 18–36 VDC) |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% – 95% non-condensing |

| Cooling Method | Passive convection |

| Mounting Type | Rack/backplane mounted |

| Dimensions (W × H × D) | 180 × 160 × 40 mm |

| Weight | 0.85 kg |

| Certifications | CE, RoHS, IEC 61131-2, UL compliant |

Applications

The ABB UA C346 AE01 is used across several critical industries where real-time, deterministic control logic and robust communication handling are vital. Key application areas include:

-

Thermal and Hydroelectric Power Plants: Controls auxiliary systems, valve logic, and turbine sequencing.

-

Industrial Automation (DCS/PLC systems): Executes process logic, manages signal conditioning, and supervises alarms.

-

Metallurgy and Rolling Mills: Synchronizes motor drives and monitors critical parameters in harsh environments.

-

Chemical Processing Plants: Manages batch control sequences, safety interlocks, and analog sensor loops.

-

Water & Wastewater Treatment: Controls flow, pH adjustment, and filtration sequencing.

-

Oil & Gas Terminals: Monitors pipeline pressures, leak detection, and SCADA integration.

Product Advantages

-

Integrated Real-Time Processing: Enables deterministic control logic execution without delay or interference.

-

Versatile Communication Compatibility: Interfaces with multiple protocols to adapt to varied automation networks.

-

Fault Tolerance and Redundancy: Supports redundant configuration for high-availability applications.

-

Advanced Diagnostics: Self-diagnosis and watchdog capabilities minimize downtime in critical systems.

-

Easy System Integration: Seamlessly interfaces with ABB Symphony and Advant systems via standardized backplanes.

-

Long-Term Software Support: Ensures sustainability through compatibility with ABB system tools and engineering suites.

-

Modular Expansion: Supports additional I/O, communication, and functional modules through backplane slots.

-

Industrial-Grade Durability: Operates reliably under high temperature, humidity, and EMC stress conditions.

-

Low Maintenance Footprint: Passive cooling and non-moving parts contribute to system longevity.

-

Custom Logic Support: Allows plant-specific ladder logic or function block configurations via ABB tools.

FAQs

-

Does the UA C346 AE01 support distributed I/O via fieldbus?

Yes, it supports distributed I/O using protocols such as Profibus and Modbus RTU over RS-485.

-

Can this module handle time-critical sequencing applications?

Absolutely. The module is built for deterministic response and supports scan cycle optimization.

-

What are the methods available for firmware upgrade on this unit?

Firmware can be updated via a serial port or internal backplane using ABB configuration tools.

-

Does it support hardware watchdog mechanisms?

Yes, it has an integrated hardware watchdog for fault recovery and fail-safe operation.

-

Can the module operate in a redundant control configuration?

Yes, it supports hot-standby redundancy with automatic switchover capabilities.

-

What is the I/O refresh rate or scan cycle time?

The scan cycle is typically under 5 ms, depending on application load and I/O count.

-

How does the module handle communication interruptions?

Communication errors are logged and trigger alarms. Logic can be configured for fail-safe action.

-

Are event logs and system diagnostics accessible remotely?

Yes, via ABB engineering tools or remote terminal interface using supported protocols.

-

Is the module programmable using standard IEC 61131-3 languages?

It supports ABB’s proprietary engineering environment, which aligns with IEC 61131 logic formats.

-

What isolation techniques are used for signal integrity?

Optical isolation and transformer-based separation are applied between control and field signal paths.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...