Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

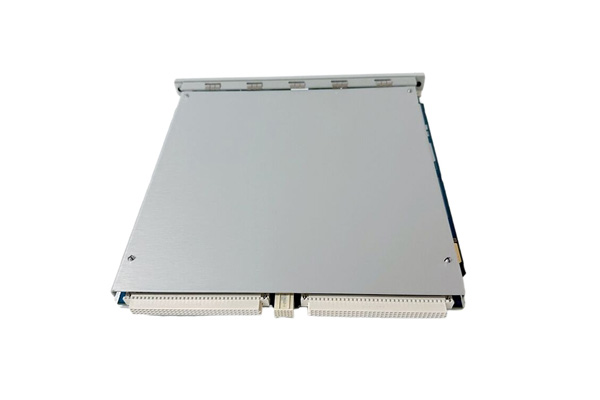

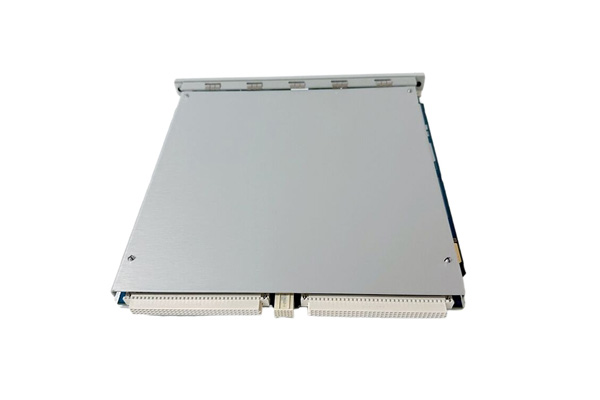

Bently Nevada 3500/22M 288055-01 Vibration Monitoring Module

Module Number:3500/22M 288055-01

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

Bently Nevada 3500/22M 288055-01 module is a vibration monitoring module developed by Bently Nevada Corporation, commonly used for vibration monitoring and health status monitoring of industrial machinery and equipment. The following is a detailed introduction about the module:

Module Overview

Product Name: Bently 3500/22M 288055-01

Type: Transient Data Interface Module (TDI)

Function: Combining the functionality of the 3500/20 Rack Interface Module (RIM) with the data collection capabilities of communication processors such as TDXnet, it is capable of continuously collecting steady-state and transient dynamic (waveform) data, and transmitting this data to the host software via Ethernet links.

Main functions and features

Real time monitoring and high-precision measurement

Capable of real-time monitoring of the vibration status of mechanical equipment, including parameters such as vibration velocity, acceleration, and displacement.

By using high-precision vibration sensors and advanced signal processing technology, the vibration signals of the equipment are accurately captured and analyzed and processed in detail.

Multiple vibration analysis functions

Provide various vibration analysis functions such as spectrum analysis, trend analysis, and fault diagnosis to help users fully understand the operating status and potential problems of the equipment.

Health status monitoring

By monitoring vibration data to evaluate the health status of mechanical equipment and detecting any signs of abnormal vibration or malfunction, it helps to promptly detect equipment failures and avoid production interruptions and losses.

Bently Nevada 3500/22M 288055-01 Vibration Monitoring Module

Module Number:3500/22M 288055-01

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

Bently Nevada 3500/22M 288055-01 module is a vibration monitoring module developed by Bently Nevada Corporation, commonly used for vibration monitoring and health status monitoring of industrial machinery and equipment. The following is a detailed introduction about the module:

Module Overview

Product Name: Bently 3500/22M 288055-01

Type: Transient Data Interface Module (TDI)

Function: Combining the functionality of the 3500/20 Rack Interface Module (RIM) with the data collection capabilities of communication processors such as TDXnet, it is capable of continuously collecting steady-state and transient dynamic (waveform) data, and transmitting this data to the host software via Ethernet links.

Main functions and features

Real time monitoring and high-precision measurement

Capable of real-time monitoring of the vibration status of mechanical equipment, including parameters such as vibration velocity, acceleration, and displacement.

By using high-precision vibration sensors and advanced signal processing technology, the vibration signals of the equipment are accurately captured and analyzed and processed in detail.

Multiple vibration analysis functions

Provide various vibration analysis functions such as spectrum analysis, trend analysis, and fault diagnosis to help users fully understand the operating status and potential problems of the equipment.

Health status monitoring

By monitoring vibration data to evaluate the health status of mechanical equipment and detecting any signs of abnormal vibration or malfunction, it helps to promptly detect equipment failures and avoid production interruptions and losses.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...