Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

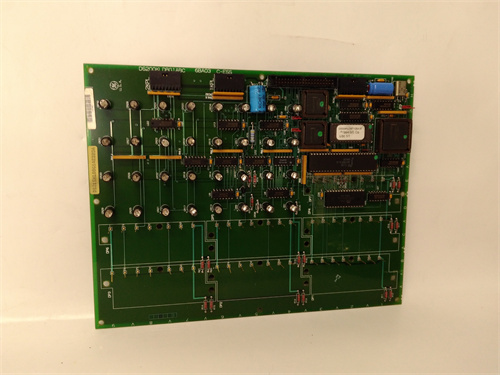

General Electric IC693PCM331 Programmable Coprocessor Module

Manufacturer:GE

Product Number:IC693PCM331

Product Type:Programmable Coprocessor Module

Origin:USA

Dimensions:140 x 140 x 35 mm

Weight:0.476 kg

Views:105

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693PCM331 Programmable Coprocessor Module is a powerful add-on processor designed for the GE Fanuc Series 90-30 PLC system, providing advanced computing capability for tasks that demand more than the main CPU’s resources.

It enables users to run custom applications, perform complex data processing, and communicate with external devices using multiple industrial protocols.

The module features an embedded 80386EX microprocessor and generous memory, allowing sophisticated control algorithms, data logging, and high-speed calculations without affecting the PLC’s primary scan time.

Its single-slot architecture makes it a space-efficient solution for plants and OEM equipment where high-performance control and data management are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IC693PCM331 |

| Module Type | Programmable Coprocessor Module |

| Compatible Platform | GE Fanuc Series 90-30 PLC |

| Processor | Intel 80386EX, 32-bit |

| User Program Memory | 1 MB SRAM, battery-backed |

| Flash Memory | 512 KB for user applications |

| Communication Ports | Two high-speed serial ports (RS-232/RS-485) |

| Supported Protocols | Modbus RTU, SNP, and custom serial communications |

| Programming Language | C, C++ or compatible high-level languages |

| Power Requirement | 5 VDC from PLC backplane |

| Operating Temperature | 0 °C to 60 °C |

| Storage Temperature | –20 °C to 70 °C |

| Mounting | Single-slot rack installation |

| Dimensions (W × H × D) | 140 x 140 x 35 mm |

| Weight | 0.476 kg |

Applications

-

Advanced Data Processing – Performs statistical analysis, complex math calculations, and large-scale data manipulation in real time.

-

Custom Protocol Conversion – Acts as a gateway between the PLC system and third-party devices by running custom communication protocols.

-

High-Speed Machine Control – Handles motion control or high-speed logic operations offloaded from the main CPU.

-

Data Logging & Storage – Captures and stores large volumes of process data for quality tracking and historical analysis.

-

Embedded OEM Solutions – Suitable for machine builders needing custom embedded logic within a standard PLC rack.

-

Process Optimization – Executes advanced algorithms for predictive maintenance or energy management.

Advantages

-

Offloaded Processing – Frees the main PLC CPU for critical logic tasks by executing compute-heavy functions on the coprocessor.

-

Flexible Programming – Supports high-level programming in C or C++, enabling creation of custom applications and algorithms.

-

Multi-Protocol Support – Dual serial ports with RS-232/RS-485 allow integration with diverse industrial networks and legacy equipment.

-

Expandable Memory – Ample SRAM and flash memory for large programs and data storage.

-

Seamless Integration – Fits directly into a Series 90-30 rack without additional power or wiring.

-

Industrial Durability – Built to operate reliably in environments with electrical noise and wide temperature fluctuations.

-

Real-Time Performance – Handles time-sensitive tasks with precise scheduling and deterministic response.

-

Maintenance Friendly – Battery-backed SRAM retains user programs during power loss, minimizing downtime.

FAQ

-

Which PLC platform is the IC693PCM331 compatible with?

It is designed specifically for the GE Fanuc Series 90-30 PLC system.

-

What programming languages can be used for the module?

It supports C and C++ or compatible high-level languages.

-

How much user program memory is available?

The module includes 1 MB of battery-backed SRAM and 512 KB of flash memory.

-

Which communication ports are provided?

Two high-speed serial ports supporting RS-232 and RS-485 interfaces.

-

Does it support Modbus RTU protocol?

Yes, Modbus RTU is natively supported.

-

Can custom serial protocols be implemented?

Yes, developers can write custom protocol handlers in C or C++.

-

What processor architecture does the module use?

It uses a 32-bit Intel 80386EX microprocessor.

-

Is external power required for operation?

No, it draws 5 VDC directly from the Series 90-30 backplane.

-

Can the coprocessor run independently of the main CPU?

Yes, it can execute tasks in parallel, communicating with the CPU as needed.

-

What is the operating temperature range?

The module operates between 0 °C and 60 °C.

General Electric IC693PCM331 Programmable Coprocessor Module

Manufacturer:GE

Product Number:IC693PCM331

Product Type:Programmable Coprocessor Module

Origin:USA

Dimensions:140 x 140 x 35 mm

Weight:0.476 kg

Views:105

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693PCM331 Programmable Coprocessor Module is a powerful add-on processor designed for the GE Fanuc Series 90-30 PLC system, providing advanced computing capability for tasks that demand more than the main CPU’s resources.

It enables users to run custom applications, perform complex data processing, and communicate with external devices using multiple industrial protocols.

The module features an embedded 80386EX microprocessor and generous memory, allowing sophisticated control algorithms, data logging, and high-speed calculations without affecting the PLC’s primary scan time.

Its single-slot architecture makes it a space-efficient solution for plants and OEM equipment where high-performance control and data management are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IC693PCM331 |

| Module Type | Programmable Coprocessor Module |

| Compatible Platform | GE Fanuc Series 90-30 PLC |

| Processor | Intel 80386EX, 32-bit |

| User Program Memory | 1 MB SRAM, battery-backed |

| Flash Memory | 512 KB for user applications |

| Communication Ports | Two high-speed serial ports (RS-232/RS-485) |

| Supported Protocols | Modbus RTU, SNP, and custom serial communications |

| Programming Language | C, C++ or compatible high-level languages |

| Power Requirement | 5 VDC from PLC backplane |

| Operating Temperature | 0 °C to 60 °C |

| Storage Temperature | –20 °C to 70 °C |

| Mounting | Single-slot rack installation |

| Dimensions (W × H × D) | 140 x 140 x 35 mm |

| Weight | 0.476 kg |

Applications

-

Advanced Data Processing – Performs statistical analysis, complex math calculations, and large-scale data manipulation in real time.

-

Custom Protocol Conversion – Acts as a gateway between the PLC system and third-party devices by running custom communication protocols.

-

High-Speed Machine Control – Handles motion control or high-speed logic operations offloaded from the main CPU.

-

Data Logging & Storage – Captures and stores large volumes of process data for quality tracking and historical analysis.

-

Embedded OEM Solutions – Suitable for machine builders needing custom embedded logic within a standard PLC rack.

-

Process Optimization – Executes advanced algorithms for predictive maintenance or energy management.

Advantages

-

Offloaded Processing – Frees the main PLC CPU for critical logic tasks by executing compute-heavy functions on the coprocessor.

-

Flexible Programming – Supports high-level programming in C or C++, enabling creation of custom applications and algorithms.

-

Multi-Protocol Support – Dual serial ports with RS-232/RS-485 allow integration with diverse industrial networks and legacy equipment.

-

Expandable Memory – Ample SRAM and flash memory for large programs and data storage.

-

Seamless Integration – Fits directly into a Series 90-30 rack without additional power or wiring.

-

Industrial Durability – Built to operate reliably in environments with electrical noise and wide temperature fluctuations.

-

Real-Time Performance – Handles time-sensitive tasks with precise scheduling and deterministic response.

-

Maintenance Friendly – Battery-backed SRAM retains user programs during power loss, minimizing downtime.

FAQ

-

Which PLC platform is the IC693PCM331 compatible with?

It is designed specifically for the GE Fanuc Series 90-30 PLC system.

-

What programming languages can be used for the module?

It supports C and C++ or compatible high-level languages.

-

How much user program memory is available?

The module includes 1 MB of battery-backed SRAM and 512 KB of flash memory.

-

Which communication ports are provided?

Two high-speed serial ports supporting RS-232 and RS-485 interfaces.

-

Does it support Modbus RTU protocol?

Yes, Modbus RTU is natively supported.

-

Can custom serial protocols be implemented?

Yes, developers can write custom protocol handlers in C or C++.

-

What processor architecture does the module use?

It uses a 32-bit Intel 80386EX microprocessor.

-

Is external power required for operation?

No, it draws 5 VDC directly from the Series 90-30 backplane.

-

Can the coprocessor run independently of the main CPU?

Yes, it can execute tasks in parallel, communicating with the CPU as needed.

-

What is the operating temperature range?

The module operates between 0 °C and 60 °C.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...