Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

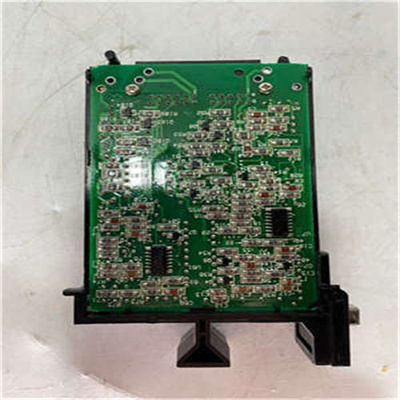

Yokogawa SSC60D-F2521 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC60D-F2521

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :13 kg

Views:10

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC60D-F2521 Duplexed Safety Control Unit is a highly reliable module designed for use in Yokogawa’s safety instrumented systems (SIS). It serves as a critical element in distributed control and safety platforms, enabling fault-tolerant control through duplexed (redundant) architecture.

This unit is engineered to meet stringent safety requirements, providing continuous process monitoring and ensuring safe plant shutdowns or protective actions when hazardous conditions are detected. With high-performance processors, dual redundancy, and integrated diagnostics, the SSC60D-F2521 ensures process integrity and minimizes the risk of system failures.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | SSC60D-F2521 Duplexed Safety Control Unit |

| Function | Safety Control and Shutdown Module |

| Architecture | Duplexed (redundant) configuration |

| Input/Output Support | Compatible with digital and analog I/O modules |

| Communication | Supports Vnet/IP and safety communication protocols |

| Power Supply | 24 V DC (typical) |

| Operating Temperature | 0 to 55 °C |

| Storage Temperature | -20 to 70 °C |

| Humidity | 10% to 90% RH (non-condensing) |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Mounting | Rack-based installation |

| Certification | IEC 61508 SIL3, TÜV certified |

| Diagnostics | Built-in self-diagnostic and fault detection |

Product Applications

-

Emergency Shutdown Systems (ESD): Safeguards processes by triggering safe plant shutdown in emergencies.

-

Fire and Gas Systems (F&G): Ensures rapid detection and response to hazardous conditions.

-

Critical Process Control: Used in oil, gas, chemical, and power industries where high availability and safety are mandatory.

-

Redundant Control Architectures: Provides uninterrupted operation even in case of single-point failures.

-

Safety Instrumented Systems (SIS): Integrates into overall plant safety solutions in compliance with SIL3 standards.

Product Advantages

-

Duplexed Architecture: Redundancy ensures uninterrupted operation and fail-safe transitions.

-

High Reliability: Meets global safety standards with SIL3 certification.

-

Advanced Diagnostics: Real-time health monitoring and self-checking improve fault detection.

-

Scalability: Can be integrated into small to large-scale safety systems.

-

Seamless Integration: Designed for compatibility with Yokogawa’s safety platforms and control networks.

-

Extended Lifecycle: Built for continuous operation in harsh industrial environments.

FAQ

Q1: What communication protocol does the SSC60D-F2521 support?

A1: It supports Vnet/IP safety communication protocol, ensuring secure and redundant network operations.

Q2: Can the SSC60D-F2521 operate independently without duplexing?

A2: While designed for duplexed operation, it can operate in simplex mode, but redundancy benefits will be lost.

Q3: What is the maximum safety integrity level supported?

A3: The SSC60D-F2521 is certified up to SIL3 under IEC 61508 standards.

Q4: Does the unit provide automatic switchover between processors?

A4: Yes, in case of a fault, automatic switchover occurs to maintain continuous operation.

Q5: How does the system perform fault diagnostics?

A5: It uses built-in self-diagnostics, cross-checks between redundant processors, and real-time error logging.

Q6: Can the SSC60D-F2521 be integrated with Yokogawa’s ProSafe-RS platform?

A6: Yes, it is fully compatible with ProSafe-RS safety systems for seamless integration.

Q7: How is communication integrity ensured in duplexed systems?

A7: Redundant communication paths and error-checking algorithms ensure message integrity.

Q8: Does the unit support hot-swappable installation?

A8: Yes, modules can be replaced without shutting down the entire system.

Q9: What type of redundancy is supported – active/active or active/standby?

A9: The unit typically operates in active/standby redundancy to ensure smooth failover.

Q10: How does it ensure synchronization between duplexed modules?

A10: Synchronization is maintained through high-speed backplane communication and continuous cross-checking.

Yokogawa SSC60D-F2521 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC60D-F2521

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :13 kg

Views:10

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC60D-F2521 Duplexed Safety Control Unit is a highly reliable module designed for use in Yokogawa’s safety instrumented systems (SIS). It serves as a critical element in distributed control and safety platforms, enabling fault-tolerant control through duplexed (redundant) architecture.

This unit is engineered to meet stringent safety requirements, providing continuous process monitoring and ensuring safe plant shutdowns or protective actions when hazardous conditions are detected. With high-performance processors, dual redundancy, and integrated diagnostics, the SSC60D-F2521 ensures process integrity and minimizes the risk of system failures.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | SSC60D-F2521 Duplexed Safety Control Unit |

| Function | Safety Control and Shutdown Module |

| Architecture | Duplexed (redundant) configuration |

| Input/Output Support | Compatible with digital and analog I/O modules |

| Communication | Supports Vnet/IP and safety communication protocols |

| Power Supply | 24 V DC (typical) |

| Operating Temperature | 0 to 55 °C |

| Storage Temperature | -20 to 70 °C |

| Humidity | 10% to 90% RH (non-condensing) |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Mounting | Rack-based installation |

| Certification | IEC 61508 SIL3, TÜV certified |

| Diagnostics | Built-in self-diagnostic and fault detection |

Product Applications

-

Emergency Shutdown Systems (ESD): Safeguards processes by triggering safe plant shutdown in emergencies.

-

Fire and Gas Systems (F&G): Ensures rapid detection and response to hazardous conditions.

-

Critical Process Control: Used in oil, gas, chemical, and power industries where high availability and safety are mandatory.

-

Redundant Control Architectures: Provides uninterrupted operation even in case of single-point failures.

-

Safety Instrumented Systems (SIS): Integrates into overall plant safety solutions in compliance with SIL3 standards.

Product Advantages

-

Duplexed Architecture: Redundancy ensures uninterrupted operation and fail-safe transitions.

-

High Reliability: Meets global safety standards with SIL3 certification.

-

Advanced Diagnostics: Real-time health monitoring and self-checking improve fault detection.

-

Scalability: Can be integrated into small to large-scale safety systems.

-

Seamless Integration: Designed for compatibility with Yokogawa’s safety platforms and control networks.

-

Extended Lifecycle: Built for continuous operation in harsh industrial environments.

FAQ

Q1: What communication protocol does the SSC60D-F2521 support?

A1: It supports Vnet/IP safety communication protocol, ensuring secure and redundant network operations.

Q2: Can the SSC60D-F2521 operate independently without duplexing?

A2: While designed for duplexed operation, it can operate in simplex mode, but redundancy benefits will be lost.

Q3: What is the maximum safety integrity level supported?

A3: The SSC60D-F2521 is certified up to SIL3 under IEC 61508 standards.

Q4: Does the unit provide automatic switchover between processors?

A4: Yes, in case of a fault, automatic switchover occurs to maintain continuous operation.

Q5: How does the system perform fault diagnostics?

A5: It uses built-in self-diagnostics, cross-checks between redundant processors, and real-time error logging.

Q6: Can the SSC60D-F2521 be integrated with Yokogawa’s ProSafe-RS platform?

A6: Yes, it is fully compatible with ProSafe-RS safety systems for seamless integration.

Q7: How is communication integrity ensured in duplexed systems?

A7: Redundant communication paths and error-checking algorithms ensure message integrity.

Q8: Does the unit support hot-swappable installation?

A8: Yes, modules can be replaced without shutting down the entire system.

Q9: What type of redundancy is supported – active/active or active/standby?

A9: The unit typically operates in active/standby redundancy to ensure smooth failover.

Q10: How does it ensure synchronization between duplexed modules?

A10: Synchronization is maintained through high-speed backplane communication and continuous cross-checking.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...