Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

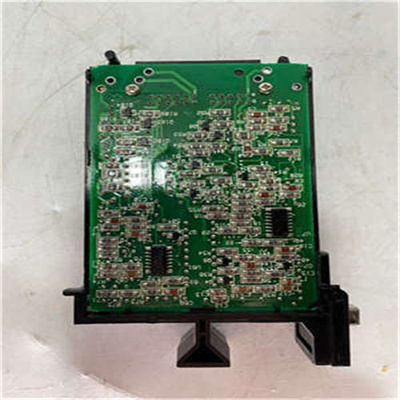

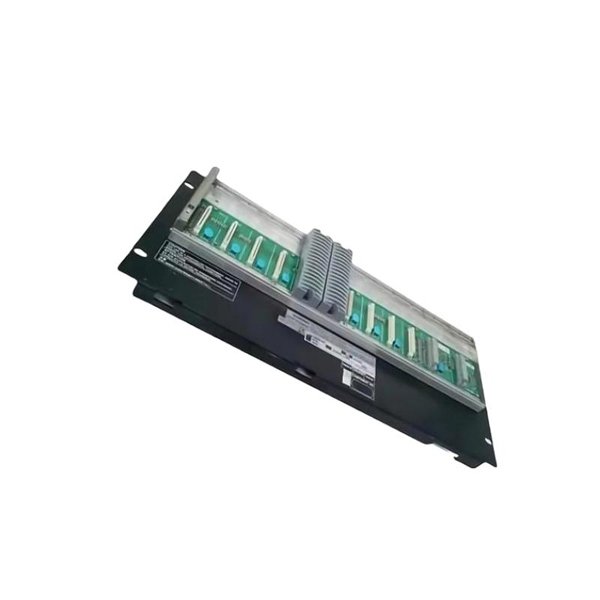

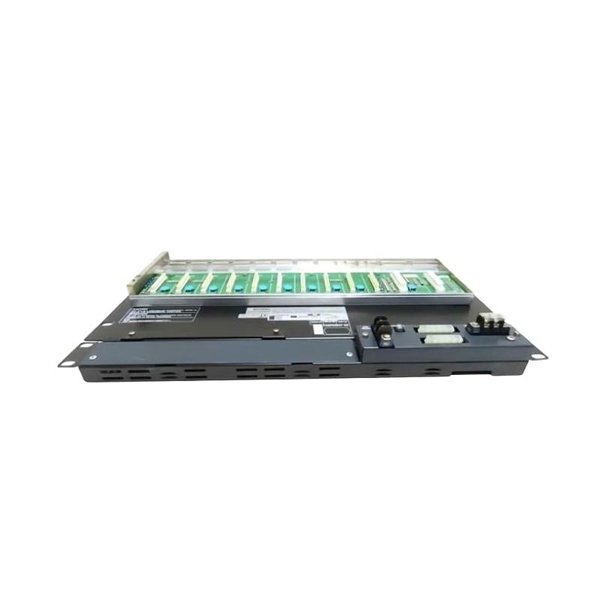

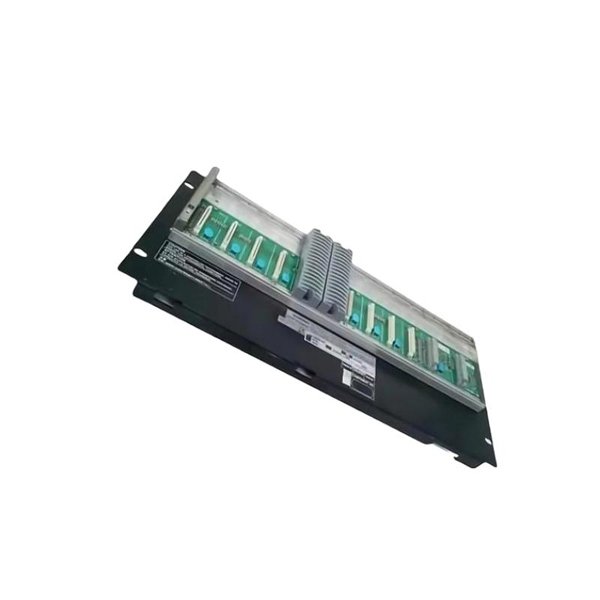

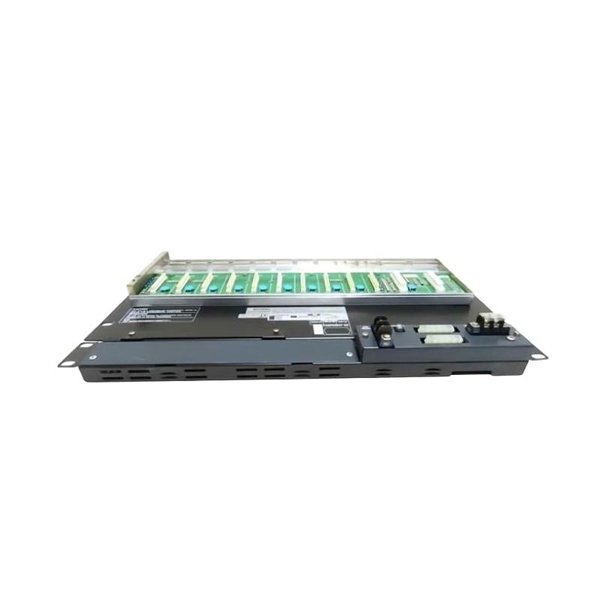

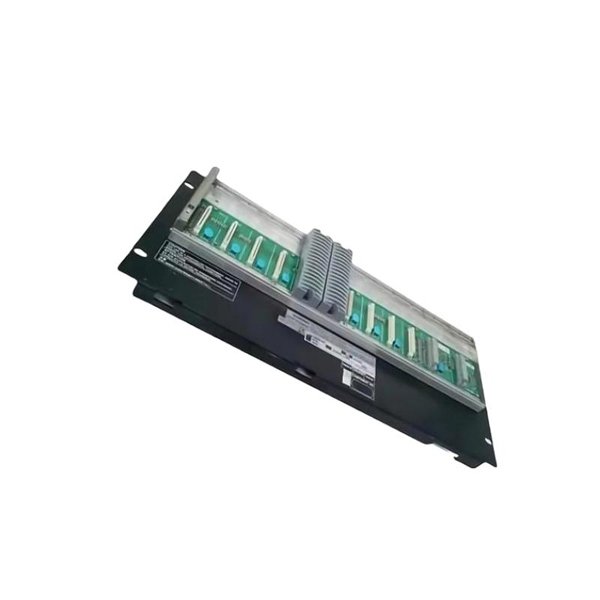

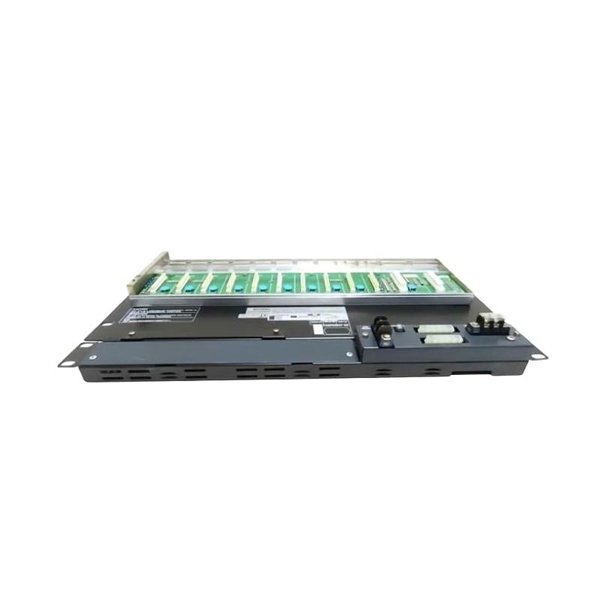

Yokogawa AFS20D Duplexed Field Control Unit

Manufacturer:Yokogawa

Product Number:AFS20D

Product Type:Duplexed Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFS20D Duplexed Field Control Unit is a highly reliable, high-performance processing unit designed as part of the CENTUM VP Distributed Control System (DCS) architecture. As a duplexed system, the AFS20D features dual redundant CPUs, ensuring uninterrupted control operations even in the event of a failure. It plays a crucial role in handling real-time process control, logic operations, and communication tasks with field instruments and I/O subsystems.

This Field Control Unit (FCU) is especially well-suited for mission-critical applications in oil and gas, petrochemicals, power generation, water treatment, pharmaceuticals, and other large-scale continuous process industries. Its robust design, modular configuration, and fail-safe redundancy provide unparalleled system availability and resilience.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AFS20D |

| System Platform | CENTUM VP |

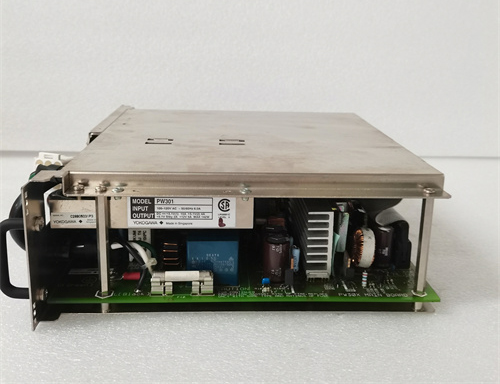

| Control Configuration | Duplexed (Redundant CPU and power supply) |

| Processor Type | Dual ARM-based CPUs (or equivalent) |

| Communication Ports | Vnet/IP, FIO (Fieldbus I/O), Gigabit Ethernet |

| Memory | Large-capacity RAM with battery backup |

| I/O Handling | Supports analog, digital, and safety I/O modules |

| Supported Protocols | Vnet/IP, Modbus, FOUNDATION Fieldbus, HART, Profibus |

| Diagnostic Features | Built-in system diagnostics, self-healing redundancy |

| Dimensions (H × W × D) | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Humidity | 5% to 95% RH (non-condensing) |

| Mounting Type | Rack or cabinet-mounted |

| Certifications | CE, ATEX, FM, CSA, TÜV (Safety System Compatible) |

Product Applications

The AFS20D Duplexed FCU is used in environments where downtime is unacceptable and process integrity is paramount. Its applications include:

-

Oil & Gas Refineries

Handles continuous process control, ESD systems, and remote I/O management across critical units.

-

Chemical and Petrochemical Plants

Manages complex chemical reactions, interlocks, and control loops with redundancy.

-

Power Generation Facilities

Supervises boiler control, turbine protection, and electrical load dispatching.

-

Water & Wastewater Treatment

Automates flow control, pump sequencing, chemical dosing, and tank level management.

-

Pharmaceutical Manufacturing

Supports validated batch processes with real-time control and secure data handling.

-

Steel & Cement Plants

Controls kilns, crushers, motors, and conveyor systems in heavy-duty environments.

Product Advantages

-

Redundant Architecture

The duplexed design ensures uninterrupted control operation even in the event of CPU, power, or communication failure.

-

Real-Time Deterministic Control

Handles time-critical applications with sub-millisecond responsiveness across complex control networks.

-

Robust Communication

Supports Yokogawa’s Vnet/IP and various open protocols for seamless field connectivity and system integration.

-

Scalable I/O Integration

Compatible with a broad range of analog, digital, safety, and third-party I/O modules.

-

Secure System Design

Includes advanced diagnostic, failover, and system integrity features to ensure safe operations.

-

Low Downtime Maintenance

Hot-swappable components and fault-tolerant software enable smooth servicing without shutdown.

-

Comprehensive Engineering Environment

Fully integrated with Yokogawa’s Engineering Workstation (ENG) and Human Interface Station (HIS) for easy configuration and monitoring.

Frequently Asked Questions (FAQ)

-

What does “duplexed” mean in the AFS20D model?

It means the unit includes dual redundant CPUs and power supplies to ensure continuous operation.

-

Which systems are compatible with the AFS20D?

It is designed for Yokogawa’s CENTUM VP platform and supports legacy integration with CENTUM CS 3000 systems.

-

Can this FCU handle both digital and analog signals?

Yes, it supports both through appropriate I/O modules (e.g., ADV series for digital, AAI for analog).

-

Is hot-swapping supported for modules?

Yes, many components within the FCU architecture are hot-swappable, allowing maintenance without downtime.

-

What communication protocols are supported?

Vnet/IP, Modbus, HART, FOUNDATION Fieldbus, and Profibus.

-

What is the memory configuration like?

It uses high-capacity RAM with battery backup for secure retention of critical data.

-

Is the AFS20D certified for hazardous environments?

Yes, it is certified by ATEX, FM, and CSA for use in hazardous and explosive zones.

-

Can it be used in safety instrumented systems?

Yes, it’s compatible with ProSafe-RS for SIS applications.

-

What is the typical response time?

It operates in real-time with deterministic cycle times of less than 10 ms.

-

Is remote engineering access supported?

Yes, engineering workstations can access the AFS20D remotely via secure protocols for monitoring and configuration.

Yokogawa AFS20D Duplexed Field Control Unit

Manufacturer:Yokogawa

Product Number:AFS20D

Product Type:Duplexed Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFS20D Duplexed Field Control Unit is a highly reliable, high-performance processing unit designed as part of the CENTUM VP Distributed Control System (DCS) architecture. As a duplexed system, the AFS20D features dual redundant CPUs, ensuring uninterrupted control operations even in the event of a failure. It plays a crucial role in handling real-time process control, logic operations, and communication tasks with field instruments and I/O subsystems.

This Field Control Unit (FCU) is especially well-suited for mission-critical applications in oil and gas, petrochemicals, power generation, water treatment, pharmaceuticals, and other large-scale continuous process industries. Its robust design, modular configuration, and fail-safe redundancy provide unparalleled system availability and resilience.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AFS20D |

| System Platform | CENTUM VP |

| Control Configuration | Duplexed (Redundant CPU and power supply) |

| Processor Type | Dual ARM-based CPUs (or equivalent) |

| Communication Ports | Vnet/IP, FIO (Fieldbus I/O), Gigabit Ethernet |

| Memory | Large-capacity RAM with battery backup |

| I/O Handling | Supports analog, digital, and safety I/O modules |

| Supported Protocols | Vnet/IP, Modbus, FOUNDATION Fieldbus, HART, Profibus |

| Diagnostic Features | Built-in system diagnostics, self-healing redundancy |

| Dimensions (H × W × D) | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Humidity | 5% to 95% RH (non-condensing) |

| Mounting Type | Rack or cabinet-mounted |

| Certifications | CE, ATEX, FM, CSA, TÜV (Safety System Compatible) |

Product Applications

The AFS20D Duplexed FCU is used in environments where downtime is unacceptable and process integrity is paramount. Its applications include:

-

Oil & Gas Refineries

Handles continuous process control, ESD systems, and remote I/O management across critical units.

-

Chemical and Petrochemical Plants

Manages complex chemical reactions, interlocks, and control loops with redundancy.

-

Power Generation Facilities

Supervises boiler control, turbine protection, and electrical load dispatching.

-

Water & Wastewater Treatment

Automates flow control, pump sequencing, chemical dosing, and tank level management.

-

Pharmaceutical Manufacturing

Supports validated batch processes with real-time control and secure data handling.

-

Steel & Cement Plants

Controls kilns, crushers, motors, and conveyor systems in heavy-duty environments.

Product Advantages

-

Redundant Architecture

The duplexed design ensures uninterrupted control operation even in the event of CPU, power, or communication failure.

-

Real-Time Deterministic Control

Handles time-critical applications with sub-millisecond responsiveness across complex control networks.

-

Robust Communication

Supports Yokogawa’s Vnet/IP and various open protocols for seamless field connectivity and system integration.

-

Scalable I/O Integration

Compatible with a broad range of analog, digital, safety, and third-party I/O modules.

-

Secure System Design

Includes advanced diagnostic, failover, and system integrity features to ensure safe operations.

-

Low Downtime Maintenance

Hot-swappable components and fault-tolerant software enable smooth servicing without shutdown.

-

Comprehensive Engineering Environment

Fully integrated with Yokogawa’s Engineering Workstation (ENG) and Human Interface Station (HIS) for easy configuration and monitoring.

Frequently Asked Questions (FAQ)

-

What does “duplexed” mean in the AFS20D model?

It means the unit includes dual redundant CPUs and power supplies to ensure continuous operation.

-

Which systems are compatible with the AFS20D?

It is designed for Yokogawa’s CENTUM VP platform and supports legacy integration with CENTUM CS 3000 systems.

-

Can this FCU handle both digital and analog signals?

Yes, it supports both through appropriate I/O modules (e.g., ADV series for digital, AAI for analog).

-

Is hot-swapping supported for modules?

Yes, many components within the FCU architecture are hot-swappable, allowing maintenance without downtime.

-

What communication protocols are supported?

Vnet/IP, Modbus, HART, FOUNDATION Fieldbus, and Profibus.

-

What is the memory configuration like?

It uses high-capacity RAM with battery backup for secure retention of critical data.

-

Is the AFS20D certified for hazardous environments?

Yes, it is certified by ATEX, FM, and CSA for use in hazardous and explosive zones.

-

Can it be used in safety instrumented systems?

Yes, it’s compatible with ProSafe-RS for SIS applications.

-

What is the typical response time?

It operates in real-time with deterministic cycle times of less than 10 ms.

-

Is remote engineering access supported?

Yes, engineering workstations can access the AFS20D remotely via secure protocols for monitoring and configuration.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...