Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

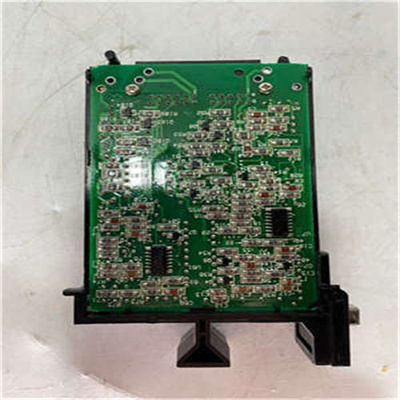

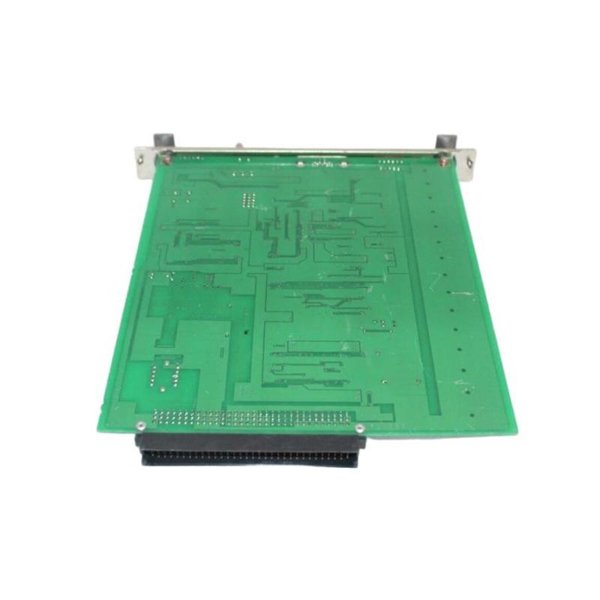

Yokogawa S9451DB Bus Module

Manufacturer:Yokogawa

Product Number:S9451DB

Product Type:Bus Module

Origin:Japan

Dimensions:25 x 254 x 203mm

Weight:0.3 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa S9451DB bus module is a high-reliability interface module designed for distributed control systems (DCS) and fieldbus networks. It provides seamless connectivity between field I/Os, sensors, and actuators with upper-level systems using standard protocols such as FOUNDATION Fieldbus, PROFIBUS, and Modbus, depending on configuration.

Its modular design, robust diagnostics, and high communication stability make it ideal for industries like process automation, chemical plants, power generation, water treatment, and smart manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Yokogawa S9451DB |

| Supported Protocols | FOUNDATION Fieldbus / PROFIBUS / Modbus |

| Power Supply | DC 24 V (20–28 VDC) |

| Power Consumption | Max. 4.5 W |

| Communication Speed | Fieldbus 31.25 kbps / PROFIBUS up to 12 Mbps |

| Interface | RS-485 / Fiber (depending on version) |

| Operating Temperature | -20 to +60 °C |

| Dimensions | 25 x 254 x 203 mm |

| Weight | 0.3 kg |

Product Applications

-

Chemical Automation

Provides precise control of reactors, pumps, and flow management, ensuring real-time process monitoring and safe closed-loop control.

-

Power and Energy

Ideal for power plants and renewable energy systems, offering high-speed data communication for boilers, turbines, and auxiliary systems.

-

Oil and Gas

Ensures reliable long-distance data transmission in refining plants, oilfields, and pipeline systems for pressure monitoring and actuator control.

-

Pharmaceutical and Biotech

Supports stringent GMP compliance by enabling precise monitoring of temperature, pressure, and flow in batch and continuous production environments.

-

Water Treatment and Environmental

Provides reliable communication for pumps, valves, and meters in wastewater treatment and industrial water systems, enabling efficient remote monitoring and automated adjustments.

-

Smart Manufacturing and Robotics

Functions as a high-speed bus interface in smart factories and automated production lines, ensuring real-time data exchange between sensors and controllers.

Product Advantages

Reliable Real-Time Communication

Industrial-grade design ensures stable communication in noisy environments.

Easy Diagnostics and Maintenance

Built-in self-test and logging features enable quick troubleshooting.

Modular Expansion

Hot-swappable design supports online expansion with minimal downtime.

Multi-Protocol Compatibility

Compatible with multiple industrial bus protocols for flexible integration.

Strong Anti-Interference

Enhanced EMC and surge suppression design for harsh environments.

Redundancy and Safety

Supports redundant power and communication channels for system continuity.

FAQ

Q: Which communication protocols does the S9451DB support?

A: FOUNDATION Fieldbus, PROFIBUS, and Modbus, depending on configuration.

Q: How to access diagnostic information?

A: Use the DCS interface or Yokogawa diagnostic tools to check logs and real-time data.

Q: How to troubleshoot packet loss?

A: Check wiring, power quality, and configuration parameters.

Q: Does it support hot-swapping?

A: Yes, but it is recommended during redundancy or maintenance windows.

Q: How to upgrade firmware?

A: Use the official upgrade tool and back up current configurations beforehand.

Q: Is remote management supported?

A: Yes, with remote diagnostics and firmware upgrades under proper security policies.

Q: How to handle high-interference environments?

A: Use shielded cables, proper grounding, or fiber-optic connections.

Q: How to implement redundancy?

A: Through dual power supplies, dual communication links, and redundant controllers.

Q: Which I/O modules are compatible?

A: Compatible with analog, digital, and temperature interface modules.

Q: How to diagnose intermittent communication issues?

A: Enable detailed logging and perform packet capture for root cause analysis.

Yokogawa S9451DB Bus Module

Manufacturer:Yokogawa

Product Number:S9451DB

Product Type:Bus Module

Origin:Japan

Dimensions:25 x 254 x 203mm

Weight:0.3 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa S9451DB bus module is a high-reliability interface module designed for distributed control systems (DCS) and fieldbus networks. It provides seamless connectivity between field I/Os, sensors, and actuators with upper-level systems using standard protocols such as FOUNDATION Fieldbus, PROFIBUS, and Modbus, depending on configuration.

Its modular design, robust diagnostics, and high communication stability make it ideal for industries like process automation, chemical plants, power generation, water treatment, and smart manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Yokogawa S9451DB |

| Supported Protocols | FOUNDATION Fieldbus / PROFIBUS / Modbus |

| Power Supply | DC 24 V (20–28 VDC) |

| Power Consumption | Max. 4.5 W |

| Communication Speed | Fieldbus 31.25 kbps / PROFIBUS up to 12 Mbps |

| Interface | RS-485 / Fiber (depending on version) |

| Operating Temperature | -20 to +60 °C |

| Dimensions | 25 x 254 x 203 mm |

| Weight | 0.3 kg |

Product Applications

-

Chemical Automation

Provides precise control of reactors, pumps, and flow management, ensuring real-time process monitoring and safe closed-loop control.

-

Power and Energy

Ideal for power plants and renewable energy systems, offering high-speed data communication for boilers, turbines, and auxiliary systems.

-

Oil and Gas

Ensures reliable long-distance data transmission in refining plants, oilfields, and pipeline systems for pressure monitoring and actuator control.

-

Pharmaceutical and Biotech

Supports stringent GMP compliance by enabling precise monitoring of temperature, pressure, and flow in batch and continuous production environments.

-

Water Treatment and Environmental

Provides reliable communication for pumps, valves, and meters in wastewater treatment and industrial water systems, enabling efficient remote monitoring and automated adjustments.

-

Smart Manufacturing and Robotics

Functions as a high-speed bus interface in smart factories and automated production lines, ensuring real-time data exchange between sensors and controllers.

Product Advantages

Reliable Real-Time Communication

Industrial-grade design ensures stable communication in noisy environments.

Easy Diagnostics and Maintenance

Built-in self-test and logging features enable quick troubleshooting.

Modular Expansion

Hot-swappable design supports online expansion with minimal downtime.

Multi-Protocol Compatibility

Compatible with multiple industrial bus protocols for flexible integration.

Strong Anti-Interference

Enhanced EMC and surge suppression design for harsh environments.

Redundancy and Safety

Supports redundant power and communication channels for system continuity.

FAQ

Q: Which communication protocols does the S9451DB support?

A: FOUNDATION Fieldbus, PROFIBUS, and Modbus, depending on configuration.

Q: How to access diagnostic information?

A: Use the DCS interface or Yokogawa diagnostic tools to check logs and real-time data.

Q: How to troubleshoot packet loss?

A: Check wiring, power quality, and configuration parameters.

Q: Does it support hot-swapping?

A: Yes, but it is recommended during redundancy or maintenance windows.

Q: How to upgrade firmware?

A: Use the official upgrade tool and back up current configurations beforehand.

Q: Is remote management supported?

A: Yes, with remote diagnostics and firmware upgrades under proper security policies.

Q: How to handle high-interference environments?

A: Use shielded cables, proper grounding, or fiber-optic connections.

Q: How to implement redundancy?

A: Through dual power supplies, dual communication links, and redundant controllers.

Q: Which I/O modules are compatible?

A: Compatible with analog, digital, and temperature interface modules.

Q: How to diagnose intermittent communication issues?

A: Enable detailed logging and perform packet capture for root cause analysis.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...