Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

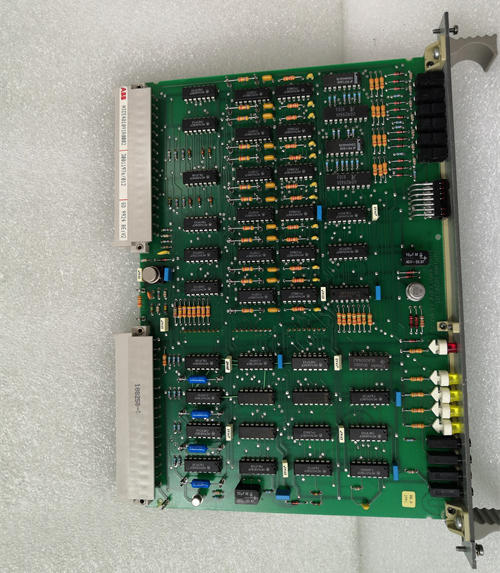

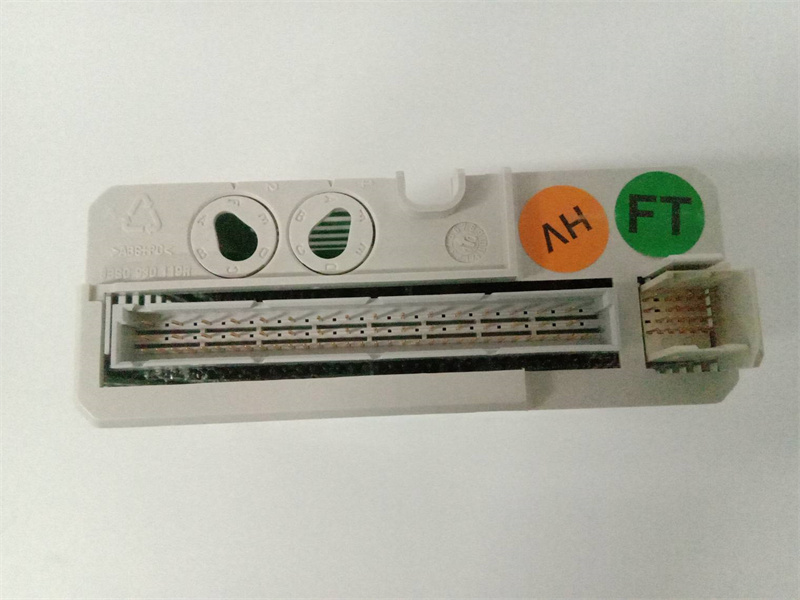

ABB DP820 3BSE013228R1 Pulse Input Module

Manufacturer:ABB

Product Number:DP820 3BSE013228R1

Condition:Pulse input module

Origin:Sweden

Dimensions:45 x 102 x 119mm

Weight:0.15 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DP820 3BSE013228R1 is a high-performance process controller designed for industrial automation and control systems. It is part of ABB’s 800xA system, offering advanced functionality for process optimization, data acquisition, and system integration. This device is widely used in industries requiring precise control, reliability, and scalability.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | DP820 3BSE013228R1 |

| Product Type | Process Controller |

| Input Voltage | 24V DC (typical) |

| Power Consumption | ≤ 15W |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions | 45 x 102 x 119mm |

| Weight | 0.15 kg |

| Communication Protocols | PROFIBUS, Modbus, Ethernet/IP |

| Memory Capacity | 512 MB Flash, 256 MB RAM |

| Certifications | CE, UL, IEC 61131-2 compliant |

| Mounting Type | DIN rail or panel mounting |

Applications

The ABB DP820 is suitable for a wide range of industrial applications, including:

-

Oil & Gas: Monitoring and controlling extraction, refining, and distribution processes.

-

Power Generation: Managing turbine control, grid stability, and energy distribution.

-

Chemical Processing: Ensuring precise reaction control and safety interlocks.

-

Water & Wastewater: Regulating filtration, pumping, and treatment systems.

-

Manufacturing: Automating production lines and quality control systems.

-

Pharmaceuticals: Maintaining strict environmental and process conditions.

Product Advantages

-

High Reliability: Built for harsh industrial environments with robust materials and design.

-

Scalability: Easily integrates into larger 800xA control systems for expanded functionality.

-

Fast Processing: Efficient real-time data handling for critical control tasks.

-

Flexible Connectivity: Supports multiple industrial communication protocols.

-

User-Friendly Configuration: Compatible with ABB’s engineering tools for easy setup.

-

Energy Efficient: Low power consumption reduces operational costs.

-

Long Lifespan: Designed for continuous operation with minimal maintenance.

Frequently Asked Questions (FAQ)

-

What industries commonly use the DP820 controller?

The DP820 is widely used in oil & gas, power plants, chemical processing, and water treatment.

-

Is the DP820 compatible with third-party PLC systems?

Yes, it supports standard protocols like Modbus and PROFIBUS for integration.

-

What is the operating temperature range?

It operates reliably between -20°C to +70°C.

-

Can the DP820 be mounted on a DIN rail?

Yes, it supports both DIN rail and panel mounting.

-

Does it require additional cooling in high-temperature environments?

No, its design ensures stable performance without extra cooling under specified conditions.

-

What software is used to configure the DP820?

ABB’s Control Builder or 800xA Engineering tools are typically used.

-

Is the memory expandable?

No, the internal memory is fixed (512 MB Flash / 256 MB RAM).

-

What certifications does the DP820 have?

It is CE, UL, and IEC 61131-2 certified.

-

How does the DP820 ensure cybersecurity?

It includes role-based access control and encrypted communications.

-

What is the expected lifespan of this controller?

With proper maintenance, it can operate for 10-15 years in industrial settings.

ABB DP820 3BSE013228R1 Pulse Input Module

Manufacturer:ABB

Product Number:DP820 3BSE013228R1

Condition:Pulse input module

Origin:Sweden

Dimensions:45 x 102 x 119mm

Weight:0.15 kg

Views:63

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DP820 3BSE013228R1 is a high-performance process controller designed for industrial automation and control systems. It is part of ABB’s 800xA system, offering advanced functionality for process optimization, data acquisition, and system integration. This device is widely used in industries requiring precise control, reliability, and scalability.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | DP820 3BSE013228R1 |

| Product Type | Process Controller |

| Input Voltage | 24V DC (typical) |

| Power Consumption | ≤ 15W |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions | 45 x 102 x 119mm |

| Weight | 0.15 kg |

| Communication Protocols | PROFIBUS, Modbus, Ethernet/IP |

| Memory Capacity | 512 MB Flash, 256 MB RAM |

| Certifications | CE, UL, IEC 61131-2 compliant |

| Mounting Type | DIN rail or panel mounting |

Applications

The ABB DP820 is suitable for a wide range of industrial applications, including:

-

Oil & Gas: Monitoring and controlling extraction, refining, and distribution processes.

-

Power Generation: Managing turbine control, grid stability, and energy distribution.

-

Chemical Processing: Ensuring precise reaction control and safety interlocks.

-

Water & Wastewater: Regulating filtration, pumping, and treatment systems.

-

Manufacturing: Automating production lines and quality control systems.

-

Pharmaceuticals: Maintaining strict environmental and process conditions.

Product Advantages

-

High Reliability: Built for harsh industrial environments with robust materials and design.

-

Scalability: Easily integrates into larger 800xA control systems for expanded functionality.

-

Fast Processing: Efficient real-time data handling for critical control tasks.

-

Flexible Connectivity: Supports multiple industrial communication protocols.

-

User-Friendly Configuration: Compatible with ABB’s engineering tools for easy setup.

-

Energy Efficient: Low power consumption reduces operational costs.

-

Long Lifespan: Designed for continuous operation with minimal maintenance.

Frequently Asked Questions (FAQ)

-

What industries commonly use the DP820 controller?

The DP820 is widely used in oil & gas, power plants, chemical processing, and water treatment.

-

Is the DP820 compatible with third-party PLC systems?

Yes, it supports standard protocols like Modbus and PROFIBUS for integration.

-

What is the operating temperature range?

It operates reliably between -20°C to +70°C.

-

Can the DP820 be mounted on a DIN rail?

Yes, it supports both DIN rail and panel mounting.

-

Does it require additional cooling in high-temperature environments?

No, its design ensures stable performance without extra cooling under specified conditions.

-

What software is used to configure the DP820?

ABB’s Control Builder or 800xA Engineering tools are typically used.

-

Is the memory expandable?

No, the internal memory is fixed (512 MB Flash / 256 MB RAM).

-

What certifications does the DP820 have?

It is CE, UL, and IEC 61131-2 certified.

-

How does the DP820 ensure cybersecurity?

It includes role-based access control and encrypted communications.

-

What is the expected lifespan of this controller?

With proper maintenance, it can operate for 10-15 years in industrial settings.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...