Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

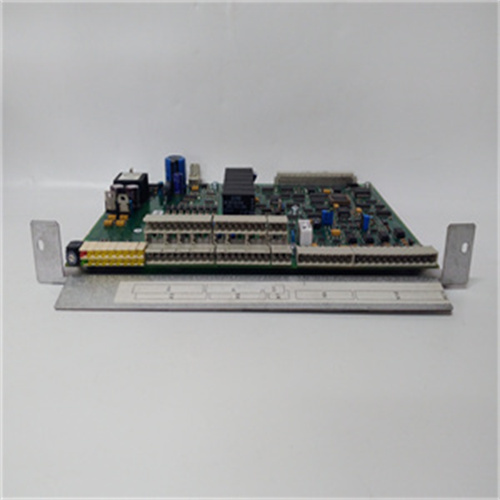

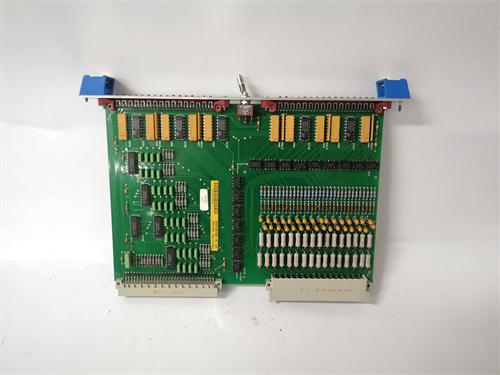

ABB DASD 147 3ASC25H280 Crane Motion Controller

Manufacturer:ABB

Product Number:DASD 147 3ASC25H280

Product Type:Crane Motion Controller

Origin:Sweden

Dimensions:1172 x 473 x 372 mm

Weight:107 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DASD 147 3ASC25H280 is a high-performance crane motion controller designed for precision control in industrial lifting and handling operations. As part of ABB’s sophisticated automation product line, this unit integrates robust hardware with advanced motion control algorithms, ensuring optimal performance for demanding crane applications. It supports seamless communication with various industrial protocols, offers real-time diagnostics, and guarantees operational reliability under tough environmental conditions.

Its modular architecture allows for easy integration into both new systems and retrofits, making it a flexible and future-proof solution for port cranes, gantry cranes, and overhead bridge cranes. With its excellent durability and dynamic control precision, the DASD 147 enhances operational safety, efficiency, and lifecycle longevity.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | DASD 147 Crane Motion Controller |

| Part Number | 3ASC25H280 |

| Manufacturer | ABB |

| Control Type | Motion controller for cranes |

| Communication Interfaces | PROFIBUS, Ethernet, CANopen (model dependent) |

| Power Supply | 24 VDC (nominal), range: 18–30 VDC |

| Input/Output Ports | Digital & analog I/O, configurable |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | DIN rail or panel mount |

| Enclosure Protection | IP20 (can be enclosed for IP65) |

| Dimensions (W × H × D) | 1172 x 473 x 372 mm |

| Weight | 107 kg |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

| Programming Interface | ABB programming environment (DriveWindow/AC500) |

| Functional Safety | Optional SIL2 / SIL3 integration |

Applications

The ABB DASD 147 motion controller is widely used in:

-

Port and Container Cranes – Precision handling of cargo in harbors and docks.

-

Overhead Bridge Cranes – Coordinated movement in manufacturing facilities.

-

Gantry Cranes – Heavy-duty material movement in warehouses and shipping yards.

-

Automated Warehouse Systems – Integration with stacker cranes and automated storage solutions.

-

Steel and Foundry Operations – For molten metal ladle handling and casting processes.

-

Marine and Shipbuilding Yards – Controlling winches, hoists, and shipyard cranes.

Product Advantages

-

High Precision Motion Control: Optimized for fast, smooth, and accurate crane movements.

-

Modular Integration: Can be integrated into both new and legacy crane systems.

-

Environmental Durability: Wide operating temperature range and shock resistance.

-

Real-Time Diagnostics: Built-in fault detection and system feedback improve safety and uptime.

-

Flexible Communication: Supports multiple industrial protocols for compatibility.

-

Safety Compliance: Meets international safety standards, supporting SIL2/SIL3 configurations.

-

Low Maintenance: Designed for long-term stability with minimal service requirements.

-

Advanced Programming Tools: Configurable through ABB’s industrial software suite.

-

Compact Design: Space-saving form factor for control panels or machinery enclosures.

Frequently Asked Questions (FAQ)

-

What is the primary function of the ABB DASD 147 3ASC25H280?

It serves as a motion controller specifically engineered for crane and hoisting applications.

-

Is this controller compatible with third-party PLCs?

Yes, it supports multiple protocols (e.g., PROFIBUS, CANopen), allowing integration with various PLC systems.

-

Can this unit operate in extreme temperatures?

Yes, it functions reliably in temperatures ranging from -25°C to +70°C.

-

Does the controller support remote diagnostics?

Yes, it supports real-time monitoring and diagnostics over industrial networks.

-

What is the lifespan of this controller?

With proper use, the DASD 147 offers a typical lifespan exceeding 10 years in industrial environments.

-

Can I mount this controller on a DIN rail?

Yes, it supports both DIN rail and panel mounting options.

-

Is this controller suitable for outdoor crane applications?

Yes, but it must be housed in an appropriate IP-rated enclosure if used outdoors.

-

What programming tools are supported?

ABB’s DriveWindow or AC500 programming environments are typically used for configuration.

-

Is there any built-in safety certification?

It can be configured to meet SIL2/SIL3 functional safety levels when used with certified components.

-

What is the recommended power supply for this controller?

A 24 VDC power supply within the range of 18–30 VDC is recommended.

ABB DASD 147 3ASC25H280 Crane Motion Controller

Manufacturer:ABB

Product Number:DASD 147 3ASC25H280

Product Type:Crane Motion Controller

Origin:Sweden

Dimensions:1172 x 473 x 372 mm

Weight:107 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DASD 147 3ASC25H280 is a high-performance crane motion controller designed for precision control in industrial lifting and handling operations. As part of ABB’s sophisticated automation product line, this unit integrates robust hardware with advanced motion control algorithms, ensuring optimal performance for demanding crane applications. It supports seamless communication with various industrial protocols, offers real-time diagnostics, and guarantees operational reliability under tough environmental conditions.

Its modular architecture allows for easy integration into both new systems and retrofits, making it a flexible and future-proof solution for port cranes, gantry cranes, and overhead bridge cranes. With its excellent durability and dynamic control precision, the DASD 147 enhances operational safety, efficiency, and lifecycle longevity.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | DASD 147 Crane Motion Controller |

| Part Number | 3ASC25H280 |

| Manufacturer | ABB |

| Control Type | Motion controller for cranes |

| Communication Interfaces | PROFIBUS, Ethernet, CANopen (model dependent) |

| Power Supply | 24 VDC (nominal), range: 18–30 VDC |

| Input/Output Ports | Digital & analog I/O, configurable |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | DIN rail or panel mount |

| Enclosure Protection | IP20 (can be enclosed for IP65) |

| Dimensions (W × H × D) | 1172 x 473 x 372 mm |

| Weight | 107 kg |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

| Programming Interface | ABB programming environment (DriveWindow/AC500) |

| Functional Safety | Optional SIL2 / SIL3 integration |

Applications

The ABB DASD 147 motion controller is widely used in:

-

Port and Container Cranes – Precision handling of cargo in harbors and docks.

-

Overhead Bridge Cranes – Coordinated movement in manufacturing facilities.

-

Gantry Cranes – Heavy-duty material movement in warehouses and shipping yards.

-

Automated Warehouse Systems – Integration with stacker cranes and automated storage solutions.

-

Steel and Foundry Operations – For molten metal ladle handling and casting processes.

-

Marine and Shipbuilding Yards – Controlling winches, hoists, and shipyard cranes.

Product Advantages

-

High Precision Motion Control: Optimized for fast, smooth, and accurate crane movements.

-

Modular Integration: Can be integrated into both new and legacy crane systems.

-

Environmental Durability: Wide operating temperature range and shock resistance.

-

Real-Time Diagnostics: Built-in fault detection and system feedback improve safety and uptime.

-

Flexible Communication: Supports multiple industrial protocols for compatibility.

-

Safety Compliance: Meets international safety standards, supporting SIL2/SIL3 configurations.

-

Low Maintenance: Designed for long-term stability with minimal service requirements.

-

Advanced Programming Tools: Configurable through ABB’s industrial software suite.

-

Compact Design: Space-saving form factor for control panels or machinery enclosures.

Frequently Asked Questions (FAQ)

-

What is the primary function of the ABB DASD 147 3ASC25H280?

It serves as a motion controller specifically engineered for crane and hoisting applications.

-

Is this controller compatible with third-party PLCs?

Yes, it supports multiple protocols (e.g., PROFIBUS, CANopen), allowing integration with various PLC systems.

-

Can this unit operate in extreme temperatures?

Yes, it functions reliably in temperatures ranging from -25°C to +70°C.

-

Does the controller support remote diagnostics?

Yes, it supports real-time monitoring and diagnostics over industrial networks.

-

What is the lifespan of this controller?

With proper use, the DASD 147 offers a typical lifespan exceeding 10 years in industrial environments.

-

Can I mount this controller on a DIN rail?

Yes, it supports both DIN rail and panel mounting options.

-

Is this controller suitable for outdoor crane applications?

Yes, but it must be housed in an appropriate IP-rated enclosure if used outdoors.

-

What programming tools are supported?

ABB’s DriveWindow or AC500 programming environments are typically used for configuration.

-

Is there any built-in safety certification?

It can be configured to meet SIL2/SIL3 functional safety levels when used with certified components.

-

What is the recommended power supply for this controller?

A 24 VDC power supply within the range of 18–30 VDC is recommended.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...