Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

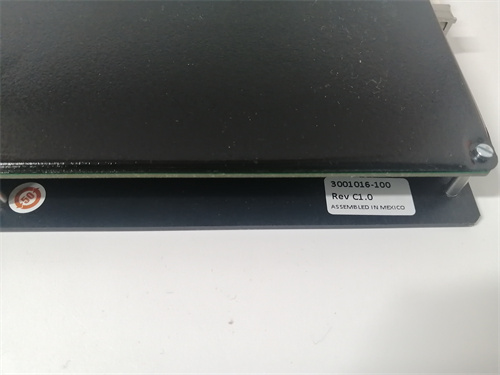

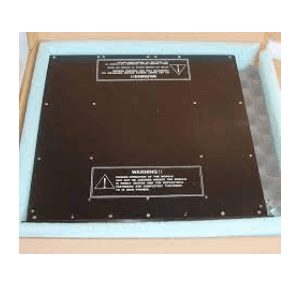

Triconex 3301 Digital Input Module

Module Number:TRICONEX 3301

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

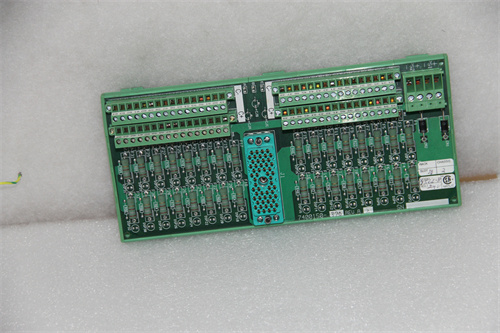

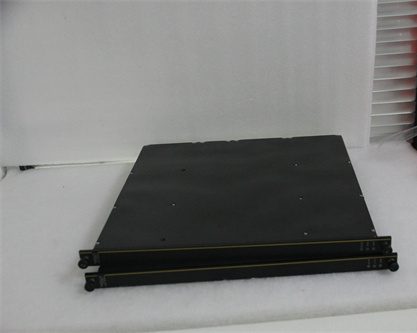

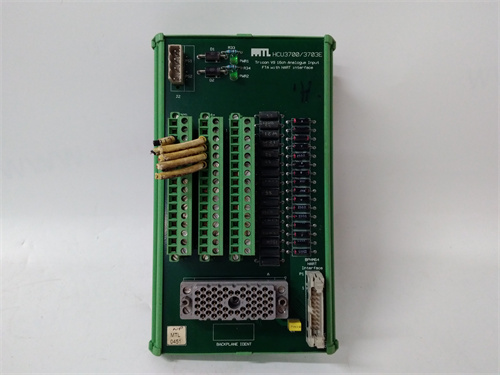

The TRICONEX 3301 module is an important input/output (I/O) module commonly used in Triconex systems to monitor and control signals and equipment in industrial processes. The following is a detailed analysis of the TRICONEX 3301 module:

Basic information

Manufacturer: Triconex

Product type: Input/Output module

Usage: Used for monitoring and controlling signals and equipment in various industrial processes, including monitoring parameters such as temperature, pressure, flow rate, as well as controlling operations such as starting and stopping motors, opening valves, etc.

Working environment: Suitable for normal temperature and pressure environments, with high reliability and stability to meet the stringent requirements of industrial environments.

Technical characteristics

Input/output channels:

The TRICONEX 3301 module typically has multiple input and output channels for reading external signals and sending control signals.

The input channel is used to monitor external signals, such as data output from sensors.

The output channel is used to send control signals to the actuator, such as controlling the start and stop of the motor or the opening and closing of the valve.

This module supports communication interfaces with the Triconex system for configuration, monitoring, and control.

It can also communicate with other control systems, PLC (Programmable Logic Controller), and SCADA (Monitoring and Data Acquisition) systems to achieve data exchange and system integration.

Redundant design:

TRICONEX systems typically adopt redundant designs, including redundant input/output modules, to ensure that the system can continue to operate in the event of a failure.

This design improves the reliability and security of the system.

Security:

The TRICONEX system focuses on safety, including safety input and output modules, used to execute safety logic to ensure the safety of process operations.

Programming and configuration:

Configuring and programming the TRICONEX 3301 module typically requires experienced engineers or technicians to ensure its proper installation, configuration, and programming to meet the specific application requirements.

Application field

The TRICONEX 3301 module is widely used in high reliability industrial applications, including but not limited to:

Oil and gas production

chemical industry

power

nuclear energy

pharmacy

These fields require extremely high reliability and safety of equipment, and the TRICONEX 3301 module plays an important role in these fields with its excellent performance and stability.

Summary

The TRICONEX 3301 module is a powerful and highly reliable input/output module that enables precise monitoring and control of industrial processes through connections with sensors, actuators, and other devices. At the same time, its redundant design and high security characteristics make the module have a wide range of application prospects in high reliability industrial applications.

Triconex 3301 Digital Input Module

Module Number:TRICONEX 3301

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The TRICONEX 3301 module is an important input/output (I/O) module commonly used in Triconex systems to monitor and control signals and equipment in industrial processes. The following is a detailed analysis of the TRICONEX 3301 module:

Basic information

Manufacturer: Triconex

Product type: Input/Output module

Usage: Used for monitoring and controlling signals and equipment in various industrial processes, including monitoring parameters such as temperature, pressure, flow rate, as well as controlling operations such as starting and stopping motors, opening valves, etc.

Working environment: Suitable for normal temperature and pressure environments, with high reliability and stability to meet the stringent requirements of industrial environments.

Technical characteristics

Input/output channels:

The TRICONEX 3301 module typically has multiple input and output channels for reading external signals and sending control signals.

The input channel is used to monitor external signals, such as data output from sensors.

The output channel is used to send control signals to the actuator, such as controlling the start and stop of the motor or the opening and closing of the valve.

This module supports communication interfaces with the Triconex system for configuration, monitoring, and control.

It can also communicate with other control systems, PLC (Programmable Logic Controller), and SCADA (Monitoring and Data Acquisition) systems to achieve data exchange and system integration.

Redundant design:

TRICONEX systems typically adopt redundant designs, including redundant input/output modules, to ensure that the system can continue to operate in the event of a failure.

This design improves the reliability and security of the system.

Security:

The TRICONEX system focuses on safety, including safety input and output modules, used to execute safety logic to ensure the safety of process operations.

Programming and configuration:

Configuring and programming the TRICONEX 3301 module typically requires experienced engineers or technicians to ensure its proper installation, configuration, and programming to meet the specific application requirements.

Application field

The TRICONEX 3301 module is widely used in high reliability industrial applications, including but not limited to:

Oil and gas production

chemical industry

power

nuclear energy

pharmacy

These fields require extremely high reliability and safety of equipment, and the TRICONEX 3301 module plays an important role in these fields with its excellent performance and stability.

Summary

The TRICONEX 3301 module is a powerful and highly reliable input/output module that enables precise monitoring and control of industrial processes through connections with sensors, actuators, and other devices. At the same time, its redundant design and high security characteristics make the module have a wide range of application prospects in high reliability industrial applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...