Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

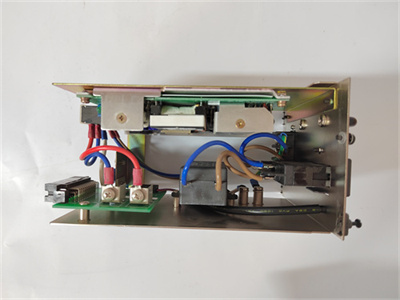

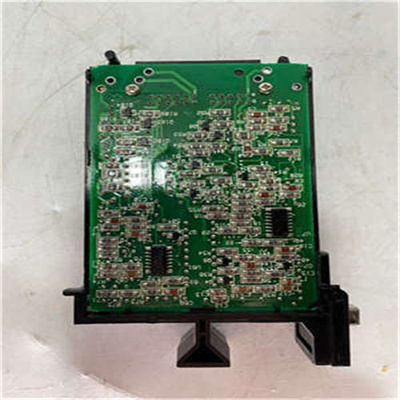

Yokogawa ABC11D-V2121 Dual-Redundant Bus Converter

Manufacturer:Yokogawa

Product Number:ABC11D-V2121

Product Type:Dual-Redundant Bus Converter

Origin:Japan

Dimensions:35 x 150 x 180 mm

Weight:1.5 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ABC11D-V2121 Dual-Redundant Bus Converter is an advanced industrial communication module designed for high-availability process automation systems. Its primary role is to provide seamless redundancy between two communication buses, ensuring continuous and error-free data transmission even if one channel fails. This capability is critical for industries that cannot tolerate downtime, such as petrochemical plants, refineries, power generation facilities, and large-scale manufacturing operations.

Built with robust industrial-grade components and a precise synchronization mechanism, the ABC11D-V2121 not only switches between channels automatically within milliseconds but also preserves data integrity during transitions. It integrates smoothly with Yokogawa’s CENTUM VP and other compatible control platforms, making it a versatile and reliable choice for mission-critical applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | ABC11D-V2121 |

| Function | Dual-Redundant Bus Converter |

| Supported Platforms | Yokogawa CENTUM VP, CS 3000, and compatible control systems |

| Redundancy Switching Time | < 10 ms |

| Communication Speed | Up to 10 Mbps |

| Operating Voltage | 24 V DC (nominal) |

| Power Consumption | 8 W (typical) |

| Diagnostics | Self-diagnostics, event logging, LED status indicators |

| Operating Temperature Range | -10°C to +60°C |

| Storage Temperature Range | -20°C to +70°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions (W × H × D) | 35 x 150 x 180 mm |

| Weight | 1.5 kg |

| Mounting | Standard rack or panel mount |

| Certification | CE, UL, CSA, IEC compliance |

Product Applications

The ABC11D-V2121 is widely applied in industrial automation scenarios that demand continuous operation and zero communication loss. Common application areas include:

-

Petrochemical and Refinery Plants – Maintaining uninterrupted communication between process control units.

-

Power Generation Facilities – Supporting redundant data links in turbine and substation control systems.

-

Pharmaceutical Manufacturing – Ensuring accurate batch control and process safety in regulated environments.

-

Water Treatment Plants – Providing reliable data exchange between distributed process controllers.

-

Pulp and Paper Industry – Guaranteeing stable automation control for high-speed production lines.

-

Oil & Gas Offshore Platforms – Withstanding vibration and harsh marine environments for critical safety systems.

Product Advantages

-

High-Speed Redundancy – Instant switchover to backup bus within milliseconds, minimizing downtime risk.

-

Data Integrity Assurance – Advanced buffering ensures no data loss or corruption during switching.

-

Hot-Swap Capability – Allows replacement without shutting down the system, reducing maintenance downtime.

-

Comprehensive Diagnostics – Real-time monitoring with visual indicators and detailed event logging.

-

Robust Environmental Resistance – Operates reliably in challenging industrial environments with wide temperature and humidity tolerance.

-

Broad Compatibility – Seamless integration with Yokogawa’s leading control systems and other compatible platforms.

FAQ

-

What is the primary function of the ABC11D-V2121?

It ensures uninterrupted data communication by managing automatic switchover between two redundant buses.

-

How fast can the module perform a redundancy switchover?

It can switch to the backup bus in less than 10 milliseconds.

-

Does it support hot-swap installation?

Yes, it can be replaced or installed without shutting down the entire system.

-

Which control systems are compatible with it?

It is compatible with Yokogawa CENTUM VP, CS 3000, and other supported platforms.

-

What communication speed can it achieve?

It supports high-speed data transmission up to 10 Mbps.

-

How does it maintain data consistency during channel switching?

The module uses synchronized buffering to ensure seamless data integrity.

-

What diagnostic features are available?

It includes self-diagnostics, LED indicators, and event logging for fault detection.

-

Can it be monitored remotely?

Yes, it supports remote monitoring via Yokogawa’s engineering tools.

-

Is it suitable for extreme industrial environments?

Yes, it is designed with industrial-grade components and wide environmental tolerance.

-

How does it ensure channel synchronization?

It continuously transmits identical data across both buses, verifying consistency in real time.

Yokogawa ABC11D-V2121 Dual-Redundant Bus Converter

Manufacturer:Yokogawa

Product Number:ABC11D-V2121

Product Type:Dual-Redundant Bus Converter

Origin:Japan

Dimensions:35 x 150 x 180 mm

Weight:1.5 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ABC11D-V2121 Dual-Redundant Bus Converter is an advanced industrial communication module designed for high-availability process automation systems. Its primary role is to provide seamless redundancy between two communication buses, ensuring continuous and error-free data transmission even if one channel fails. This capability is critical for industries that cannot tolerate downtime, such as petrochemical plants, refineries, power generation facilities, and large-scale manufacturing operations.

Built with robust industrial-grade components and a precise synchronization mechanism, the ABC11D-V2121 not only switches between channels automatically within milliseconds but also preserves data integrity during transitions. It integrates smoothly with Yokogawa’s CENTUM VP and other compatible control platforms, making it a versatile and reliable choice for mission-critical applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | ABC11D-V2121 |

| Function | Dual-Redundant Bus Converter |

| Supported Platforms | Yokogawa CENTUM VP, CS 3000, and compatible control systems |

| Redundancy Switching Time | < 10 ms |

| Communication Speed | Up to 10 Mbps |

| Operating Voltage | 24 V DC (nominal) |

| Power Consumption | 8 W (typical) |

| Diagnostics | Self-diagnostics, event logging, LED status indicators |

| Operating Temperature Range | -10°C to +60°C |

| Storage Temperature Range | -20°C to +70°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions (W × H × D) | 35 x 150 x 180 mm |

| Weight | 1.5 kg |

| Mounting | Standard rack or panel mount |

| Certification | CE, UL, CSA, IEC compliance |

Product Applications

The ABC11D-V2121 is widely applied in industrial automation scenarios that demand continuous operation and zero communication loss. Common application areas include:

-

Petrochemical and Refinery Plants – Maintaining uninterrupted communication between process control units.

-

Power Generation Facilities – Supporting redundant data links in turbine and substation control systems.

-

Pharmaceutical Manufacturing – Ensuring accurate batch control and process safety in regulated environments.

-

Water Treatment Plants – Providing reliable data exchange between distributed process controllers.

-

Pulp and Paper Industry – Guaranteeing stable automation control for high-speed production lines.

-

Oil & Gas Offshore Platforms – Withstanding vibration and harsh marine environments for critical safety systems.

Product Advantages

-

High-Speed Redundancy – Instant switchover to backup bus within milliseconds, minimizing downtime risk.

-

Data Integrity Assurance – Advanced buffering ensures no data loss or corruption during switching.

-

Hot-Swap Capability – Allows replacement without shutting down the system, reducing maintenance downtime.

-

Comprehensive Diagnostics – Real-time monitoring with visual indicators and detailed event logging.

-

Robust Environmental Resistance – Operates reliably in challenging industrial environments with wide temperature and humidity tolerance.

-

Broad Compatibility – Seamless integration with Yokogawa’s leading control systems and other compatible platforms.

FAQ

-

What is the primary function of the ABC11D-V2121?

It ensures uninterrupted data communication by managing automatic switchover between two redundant buses.

-

How fast can the module perform a redundancy switchover?

It can switch to the backup bus in less than 10 milliseconds.

-

Does it support hot-swap installation?

Yes, it can be replaced or installed without shutting down the entire system.

-

Which control systems are compatible with it?

It is compatible with Yokogawa CENTUM VP, CS 3000, and other supported platforms.

-

What communication speed can it achieve?

It supports high-speed data transmission up to 10 Mbps.

-

How does it maintain data consistency during channel switching?

The module uses synchronized buffering to ensure seamless data integrity.

-

What diagnostic features are available?

It includes self-diagnostics, LED indicators, and event logging for fault detection.

-

Can it be monitored remotely?

Yes, it supports remote monitoring via Yokogawa’s engineering tools.

-

Is it suitable for extreme industrial environments?

Yes, it is designed with industrial-grade components and wide environmental tolerance.

-

How does it ensure channel synchronization?

It continuously transmits identical data across both buses, verifying consistency in real time.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...