Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

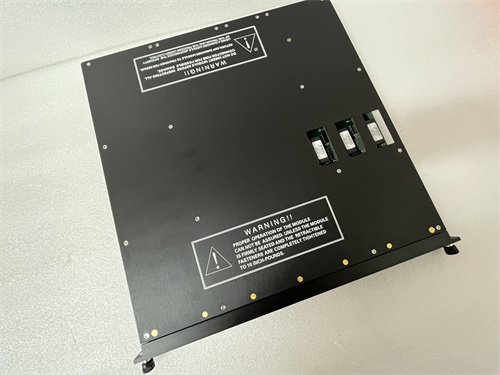

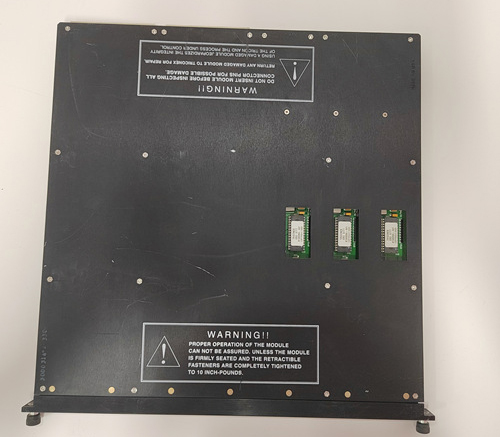

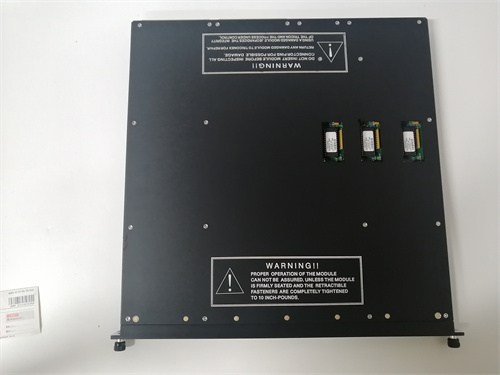

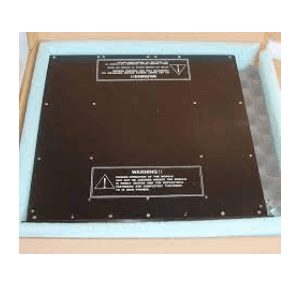

Triconex 4118 Compact 4-axis Controller

Module Number:TRICONEX 4118

Product status:Discontinued

Orignal Country:U.S.A/ FRANCE

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

TRICONEX 4118 is a product widely used in the field of industrial control, with a variety of excellent features and functions.

Firstly, TRICONEX 4118 is a compact 4-axis controller that is perfect for highly dynamic applications. It can control four brushless DC or stepper motors with a rated power of up to 150W per shaft. In addition, it also supports Hall sensors or incremental or SSI encoders to provide feedback on motor position, ensuring accurate motion control.

Secondly, TRICONEX 4118 has powerful programming and configuration capabilities. Users can configure and program modules based on specific needs using appropriate software tools. This enables it to adapt to various industrial automation applications and meet different control needs.

In addition, TRICONEX 4118 also supports multiple motion trajectory settings, allowing users to quickly and easily select through digital input bit configurations. This makes it more flexible and efficient in executing complex motion control tasks.

In terms of hardware specifications, TRICONEX 4118 features high-density input/output and dual independent power supply. It has 32 input points and 32 output points, with a maximum output current of 2A, a wide operating temperature range, and dimensions of 118mm x 20mm x 139mm.

In terms of application, TRICONEX 4118 plays an important role in the automation of material processing, assembly, and distribution operations. It supports a shift towards just in case manufacturing, meeting the interest of end users in using intelligent conveyor belts for product tracking. In addition, TRICONEX 4118 is widely used in conveyor design, including conveyor belts and drum designs, as well as tray conveyors.

Triconex 4118 Compact 4-axis Controller

Module Number:TRICONEX 4118

Product status:Discontinued

Orignal Country:U.S.A/ FRANCE

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

TRICONEX 4118 is a product widely used in the field of industrial control, with a variety of excellent features and functions.

Firstly, TRICONEX 4118 is a compact 4-axis controller that is perfect for highly dynamic applications. It can control four brushless DC or stepper motors with a rated power of up to 150W per shaft. In addition, it also supports Hall sensors or incremental or SSI encoders to provide feedback on motor position, ensuring accurate motion control.

Secondly, TRICONEX 4118 has powerful programming and configuration capabilities. Users can configure and program modules based on specific needs using appropriate software tools. This enables it to adapt to various industrial automation applications and meet different control needs.

In addition, TRICONEX 4118 also supports multiple motion trajectory settings, allowing users to quickly and easily select through digital input bit configurations. This makes it more flexible and efficient in executing complex motion control tasks.

In terms of hardware specifications, TRICONEX 4118 features high-density input/output and dual independent power supply. It has 32 input points and 32 output points, with a maximum output current of 2A, a wide operating temperature range, and dimensions of 118mm x 20mm x 139mm.

In terms of application, TRICONEX 4118 plays an important role in the automation of material processing, assembly, and distribution operations. It supports a shift towards just in case manufacturing, meeting the interest of end users in using intelligent conveyor belts for product tracking. In addition, TRICONEX 4118 is widely used in conveyor design, including conveyor belts and drum designs, as well as tray conveyors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...