Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

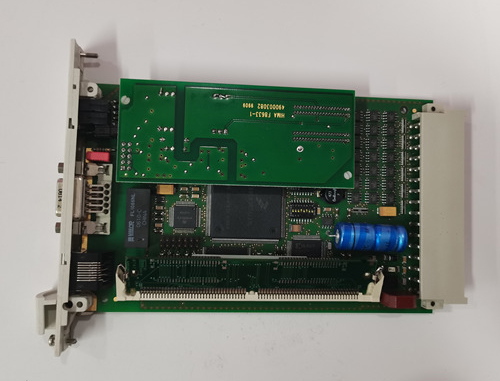

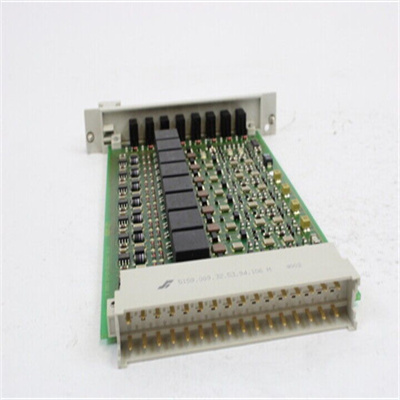

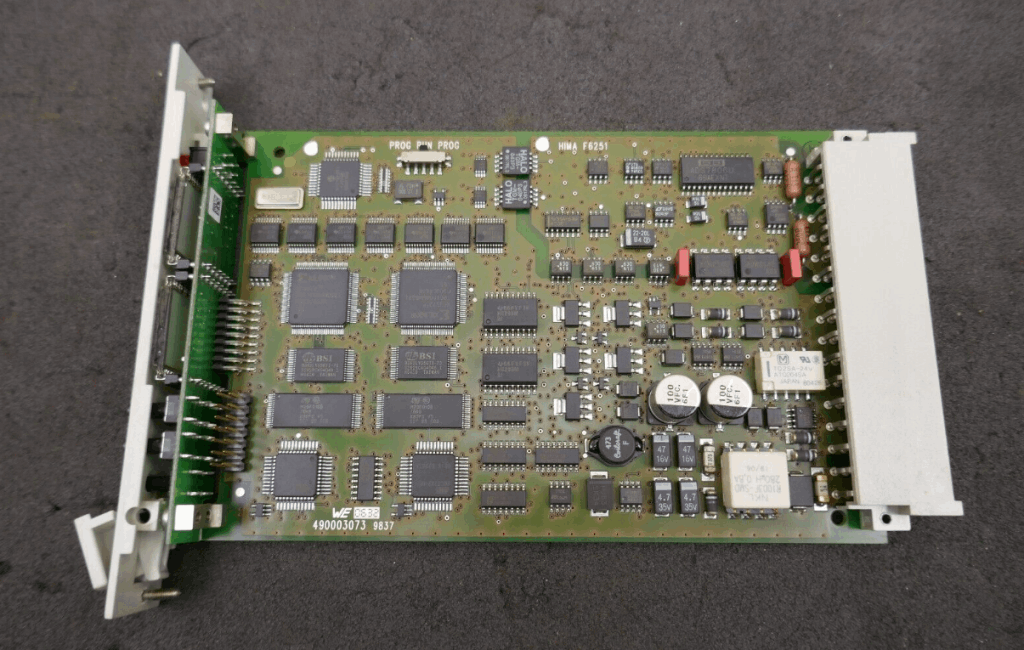

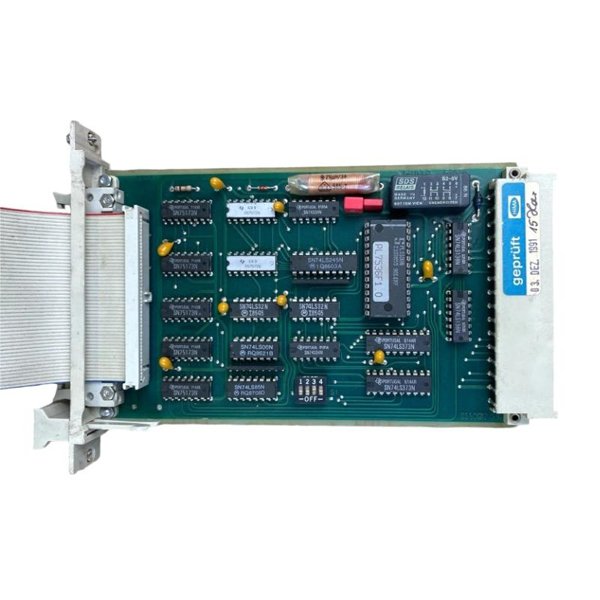

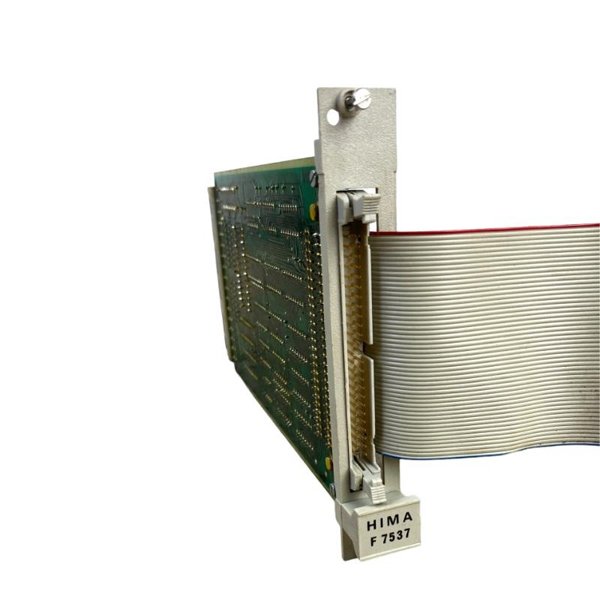

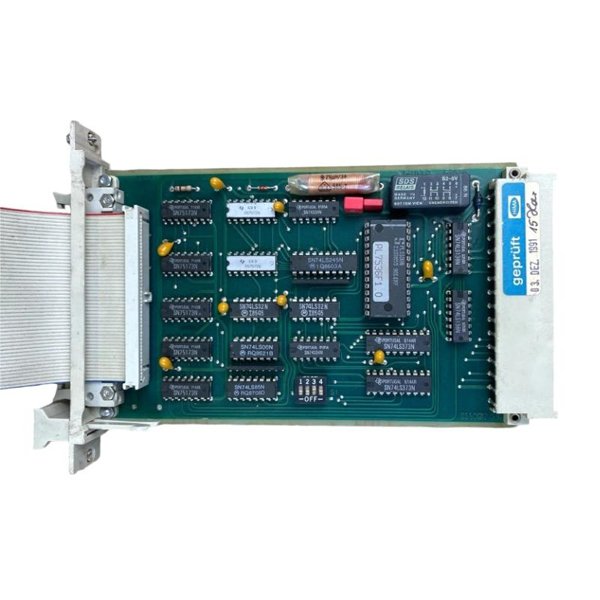

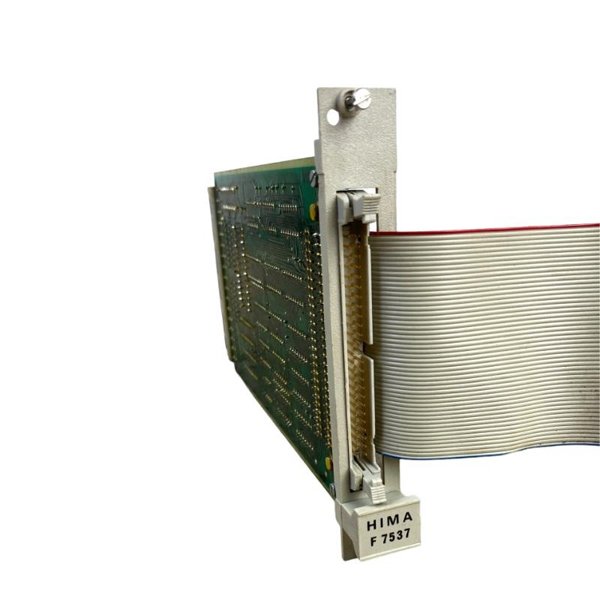

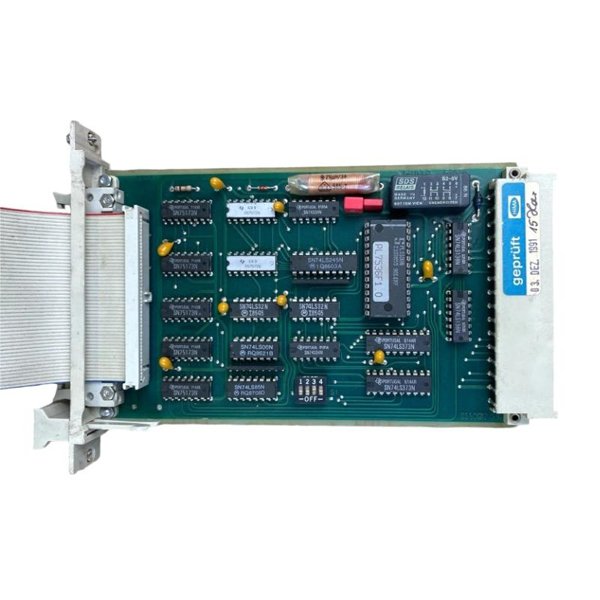

Hima F7537 Printed Circuit Board Module

Manufacturer:HIMA

Product Number:F7537

Product Type:Printed Circuit Board Module

Origin:Germany

Dimensions:180 × 30 × 250 mm

Weight:0.136 kg

Views:173

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F7537 Printed Circuit Board (PCB) Module is a reliable and high-performance component designed for integration within HIMA’s safety and automation systems. It is primarily used for handling specialized control, monitoring, and signal processing tasks in critical industrial environments. The module is built on a durable printed circuit board platform, offering high-density signal processing capabilities and advanced diagnostic features.

The F7537 ensures operational reliability in industries that require continuous availability and strict compliance with international safety standards. It is suitable for use in distributed control systems, emergency shutdown systems, and safety instrumented systems where fault tolerance and robust performance are essential.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | HIMA F7537 Printed Circuit Board Module |

| Function | Signal processing and control within HIMA automation systems |

| Input/Output Capacity | Up to 16 configurable I/O channels (digital or analog depending on setup) |

| Processing Capability | High-speed signal processing for real-time applications |

| Communication Interfaces | Supports HIMA proprietary bus, Modbus, and system backplane communication |

| Power Supply | 24 VDC (nominal) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

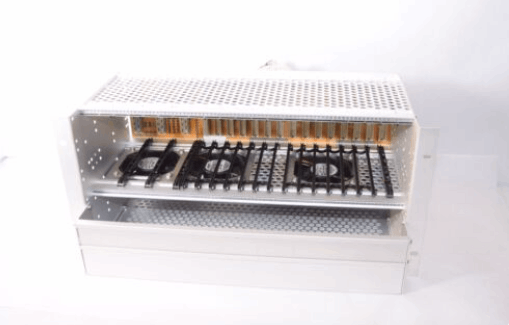

| Cooling Method | Natural convection or forced air (rack mounted) |

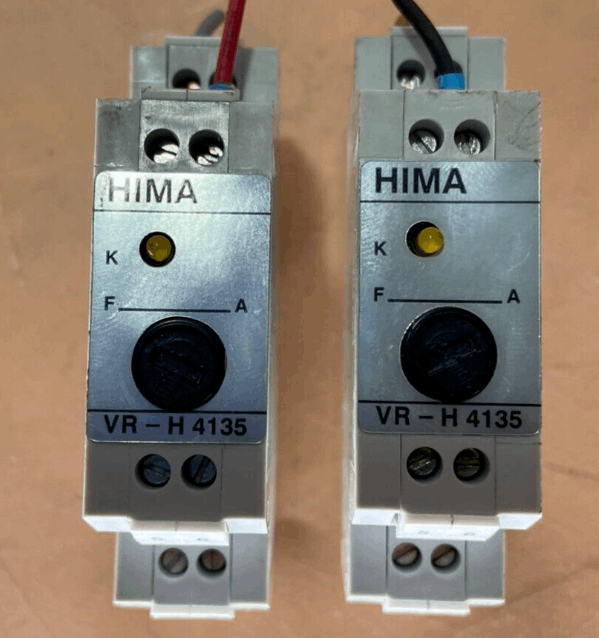

| Diagnostic Features | Built-in self-test, fault indication LEDs, error logging |

| Redundancy Support | Yes, compatible with redundant configurations |

| Mounting Type | Rack-mounted PCB module |

| Dimensions (H × W × D) | 180 × 30 × 250 mm |

| Weight | 0.136 kg |

Product Applications

The HIMA F7537 PCB Module is widely used in mission-critical industries requiring high levels of automation, monitoring, and safety. Typical applications include:

Oil & Gas Industry: Monitoring drilling operations, safety interlocks, and wellhead shutdown systems.

Chemical & Petrochemical Plants: Reactor safety management, emergency shutdown logic, and alarm handling.

Power Generation: Turbine monitoring, boiler protection, and auxiliary system safety.

Transportation Systems: Rail safety logic, industrial transport monitoring, and signaling control.

Manufacturing: Process automation, machine interlocks, and production line safety integration.

Renewable Energy: Wind and solar farm control panels, grid safety, and substation protection.

Product Advantages

High Reliability: Designed for continuous industrial use with robust PCB construction.

Advanced Diagnostics: Built-in self-testing and LED fault indication for fast troubleshooting.

Scalable Architecture: Easily integrated into larger HIMA safety and automation systems.

Flexibility: Configurable I/O channels for different application requirements.

Compatibility: Works seamlessly with other HIMA modules for complete automation solutions.

Safety Certified: Complies with international standards such as IEC 61508, making it suitable for SIL-rated safety systems.

Redundancy Ready: Supports redundant installations for maximum uptime and reliability.

FAQ

What type of I/O channels does the F7537 support?

The module supports configurable digital or analog channels depending on the system requirements.

Does the module include self-diagnostic functions?

Yes, it has integrated self-test features, LED indicators, and fault logging for quick fault detection.

Is redundancy supported by the F7537?

Yes, it is compatible with redundant system setups to ensure continuous operation during faults.

Which communication methods are supported?

The module communicates through HIMA’s proprietary system bus, Modbus, and standard backplane connections.

Can the F7537 be replaced while the system is running?

Yes, the module is hot-swappable, enabling replacement without requiring a full system shutdown.

How many I/O channels can the F7537 manage?

It can handle up to 16 configurable channels, depending on whether the application requires digital or analog inputs/outputs.

Is the module compatible with older HIMA rack systems?

Yes, it is backward compatible with selected legacy HIMA systems, ensuring flexible upgrades.

How does the F7537 manage channel faults?

Faulty channels are automatically isolated, ensuring that the rest of the system continues to operate without disruption.

Does the F7537 support SIL-rated applications?

Yes, the module is suitable for integration into SIL-rated safety instrumented systems (IEC 61508 compliant).

What cooling method is recommended for the F7537 in dense systems?

While natural convection is sufficient in most cases, forced rack-mounted cooling is recommended for high-density installations.

Hima F7537 Printed Circuit Board Module

Manufacturer:HIMA

Product Number:F7537

Product Type:Printed Circuit Board Module

Origin:Germany

Dimensions:180 × 30 × 250 mm

Weight:0.136 kg

Views:173

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F7537 Printed Circuit Board (PCB) Module is a reliable and high-performance component designed for integration within HIMA’s safety and automation systems. It is primarily used for handling specialized control, monitoring, and signal processing tasks in critical industrial environments. The module is built on a durable printed circuit board platform, offering high-density signal processing capabilities and advanced diagnostic features.

The F7537 ensures operational reliability in industries that require continuous availability and strict compliance with international safety standards. It is suitable for use in distributed control systems, emergency shutdown systems, and safety instrumented systems where fault tolerance and robust performance are essential.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | HIMA F7537 Printed Circuit Board Module |

| Function | Signal processing and control within HIMA automation systems |

| Input/Output Capacity | Up to 16 configurable I/O channels (digital or analog depending on setup) |

| Processing Capability | High-speed signal processing for real-time applications |

| Communication Interfaces | Supports HIMA proprietary bus, Modbus, and system backplane communication |

| Power Supply | 24 VDC (nominal) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Cooling Method | Natural convection or forced air (rack mounted) |

| Diagnostic Features | Built-in self-test, fault indication LEDs, error logging |

| Redundancy Support | Yes, compatible with redundant configurations |

| Mounting Type | Rack-mounted PCB module |

| Dimensions (H × W × D) | 180 × 30 × 250 mm |

| Weight | 0.136 kg |

Product Applications

The HIMA F7537 PCB Module is widely used in mission-critical industries requiring high levels of automation, monitoring, and safety. Typical applications include:

Oil & Gas Industry: Monitoring drilling operations, safety interlocks, and wellhead shutdown systems.

Chemical & Petrochemical Plants: Reactor safety management, emergency shutdown logic, and alarm handling.

Power Generation: Turbine monitoring, boiler protection, and auxiliary system safety.

Transportation Systems: Rail safety logic, industrial transport monitoring, and signaling control.

Manufacturing: Process automation, machine interlocks, and production line safety integration.

Renewable Energy: Wind and solar farm control panels, grid safety, and substation protection.

Product Advantages

High Reliability: Designed for continuous industrial use with robust PCB construction.

Advanced Diagnostics: Built-in self-testing and LED fault indication for fast troubleshooting.

Scalable Architecture: Easily integrated into larger HIMA safety and automation systems.

Flexibility: Configurable I/O channels for different application requirements.

Compatibility: Works seamlessly with other HIMA modules for complete automation solutions.

Safety Certified: Complies with international standards such as IEC 61508, making it suitable for SIL-rated safety systems.

Redundancy Ready: Supports redundant installations for maximum uptime and reliability.

FAQ

What type of I/O channels does the F7537 support?

The module supports configurable digital or analog channels depending on the system requirements.

Does the module include self-diagnostic functions?

Yes, it has integrated self-test features, LED indicators, and fault logging for quick fault detection.

Is redundancy supported by the F7537?

Yes, it is compatible with redundant system setups to ensure continuous operation during faults.

Which communication methods are supported?

The module communicates through HIMA’s proprietary system bus, Modbus, and standard backplane connections.

Can the F7537 be replaced while the system is running?

Yes, the module is hot-swappable, enabling replacement without requiring a full system shutdown.

How many I/O channels can the F7537 manage?

It can handle up to 16 configurable channels, depending on whether the application requires digital or analog inputs/outputs.

Is the module compatible with older HIMA rack systems?

Yes, it is backward compatible with selected legacy HIMA systems, ensuring flexible upgrades.

How does the F7537 manage channel faults?

Faulty channels are automatically isolated, ensuring that the rest of the system continues to operate without disruption.

Does the F7537 support SIL-rated applications?

Yes, the module is suitable for integration into SIL-rated safety instrumented systems (IEC 61508 compliant).

What cooling method is recommended for the F7537 in dense systems?

While natural convection is sufficient in most cases, forced rack-mounted cooling is recommended for high-density installations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...