Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

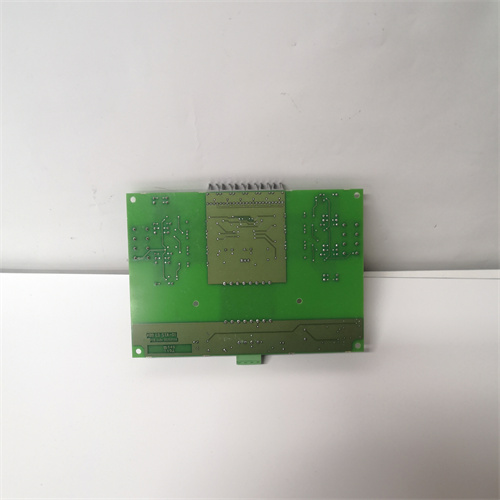

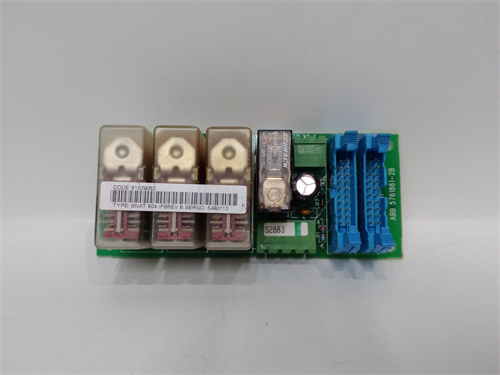

ABB SDCS-CON-3A 3ADT220120R0003 Control Board

Manufacturer:ABB

Product Number:SDCS-CON-3A 3ADT220120R0003

Product Type:Control Board

Origin:Sweden

Dimensions:250 x 200 x 20 mm

Weight:0.336 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB SDCS-CON-3A, part number 3ADT220120R0003, is a control board specifically designed for use in ABB DCS 500 and DCS 600 series DC drive systems. Acting as the central communication and control hub, this board is responsible for managing signal processing, system diagnostics, and interfacing between various internal and external modules within the drive system.

Engineered for industrial automation and motor control applications, the SDCS-CON-3A board is optimized for high reliability, stable performance, and precise control. Its rugged construction and long-term service life make it a critical component in maintaining high uptime and operational efficiency in demanding environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model | SDCS-CON-3A |

| Part Number | 3ADT220120R0003 |

| Manufacturer | ABB |

| Series | DCS 500 / DCS 600 |

| Product Type | Control Board |

| Function | Communication and control interface for DC drive systems |

| Voltage Supply | Supplied via DCS main unit |

| Processor | High-speed microcontroller for drive and I/O management |

| Interface Support | Analog, Digital, Serial communication (RS-232/RS-485) |

| Diagnostic LEDs | Yes, for status and fault indication |

| Firmware Upgradable | Yes |

| Compatible Drives | DCS500, DCS600 (selected models) |

| Mounting Type | Plug-in PCB for drive chassis |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -25°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions (H × W × D) | 250 x 200 x 20 mm |

| Weight | 0.336 kg |

| Certifications | CE, RoHS compliant |

| Protection | Conformal coating for industrial resistance |

Product Applications

The SDCS-CON-3A control board is widely used in industrial sectors where DC drive systems are prevalent. Its main applications include:

Steel and Metal Processing Plants

Used in rolling mills and hoisting systems for precise DC motor control.

Paper & Pulp Industry

Drives calenders, coaters, and winders with high torque requirements.

Mining Operations

Controls conveyors, crushers, and heavy-duty DC-driven equipment.

Marine and Offshore Equipment

For propulsion systems, winches, and cranes with DCS drive technology.

Automotive Manufacturing

Employed in paint lines, presses, and robotic arms requiring variable DC control.

Energy and Power

Used in wind tunnel testing setups and generator control in test rigs.

Product Advantages

High Compatibility

Fully compatible with ABB’s DCS500 and DCS600 series, ensuring reliable integration and upgrade flexibility.

Robust Communication

Supports analog and serial interfaces, enabling seamless interaction with PLCs, HMIs, and remote monitoring systems.

Enhanced Diagnostics

Onboard LEDs and built-in self-diagnostics help in quick fault detection and minimal troubleshooting time.

Compact Design

Space-saving form factor allows installation in tight control cabinets.

Industrial Durability

Conformal coating and high-tolerance components ensure long life in harsh industrial conditions.

Upgradeable Firmware

Supports firmware updates for extended functionality and compatibility with new features.

Stabilized Performance

Ensures reliable operation in long production cycles without performance drift.

Service-Friendly

Modular plug-in design makes replacement and servicing simple and efficient.

Frequently Asked Questions (FAQ)

1. What is the main purpose of the SDCS-CON-3A board?

It functions as the control and communication interface for ABB’s DCS 500/600 DC drive systems.

2. Is it compatible with the DCS800 series?

No, the SDCS-CON-3A is designed for the DCS 500 and DCS 600 series only.

3. Can the board be upgraded with new firmware?

Yes, firmware updates can be performed via a serial interface using ABB service tools.

4. Does this board come pre-configured?

No, configuration is done during commissioning through the drive’s user interface or software.

5. What happens if the board fails during operation?

The drive will signal a fault, and the system will either shut down or switch to a safe state.

6. Are diagnostic LEDs available?

Yes, the board features LEDs for visual status and fault indication.

7. Can I use this board in non-ABB drive systems?

No, it is proprietary to ABB DCS 500/600 drive systems and is not compatible with third-party drives.

8. Is it possible to replace the board without recalibrating the whole system?

In many cases, yes. If parameters are stored externally or on EEPROM, system recalibration may not be needed.

9. Does the board have protection against dust or corrosion?

Yes, it is coated with a protective layer to withstand industrial environmental conditions.

10. What kind of diagnostic features are built into the SDCS-CON-3A?

It has onboard status LEDs and supports fault logging via the drive’s monitoring system.

ABB SDCS-CON-3A 3ADT220120R0003 Control Board

Manufacturer:ABB

Product Number:SDCS-CON-3A 3ADT220120R0003

Product Type:Control Board

Origin:Sweden

Dimensions:250 x 200 x 20 mm

Weight:0.336 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB SDCS-CON-3A, part number 3ADT220120R0003, is a control board specifically designed for use in ABB DCS 500 and DCS 600 series DC drive systems. Acting as the central communication and control hub, this board is responsible for managing signal processing, system diagnostics, and interfacing between various internal and external modules within the drive system.

Engineered for industrial automation and motor control applications, the SDCS-CON-3A board is optimized for high reliability, stable performance, and precise control. Its rugged construction and long-term service life make it a critical component in maintaining high uptime and operational efficiency in demanding environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model | SDCS-CON-3A |

| Part Number | 3ADT220120R0003 |

| Manufacturer | ABB |

| Series | DCS 500 / DCS 600 |

| Product Type | Control Board |

| Function | Communication and control interface for DC drive systems |

| Voltage Supply | Supplied via DCS main unit |

| Processor | High-speed microcontroller for drive and I/O management |

| Interface Support | Analog, Digital, Serial communication (RS-232/RS-485) |

| Diagnostic LEDs | Yes, for status and fault indication |

| Firmware Upgradable | Yes |

| Compatible Drives | DCS500, DCS600 (selected models) |

| Mounting Type | Plug-in PCB for drive chassis |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -25°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions (H × W × D) | 250 x 200 x 20 mm |

| Weight | 0.336 kg |

| Certifications | CE, RoHS compliant |

| Protection | Conformal coating for industrial resistance |

Product Applications

The SDCS-CON-3A control board is widely used in industrial sectors where DC drive systems are prevalent. Its main applications include:

Steel and Metal Processing Plants

Used in rolling mills and hoisting systems for precise DC motor control.

Paper & Pulp Industry

Drives calenders, coaters, and winders with high torque requirements.

Mining Operations

Controls conveyors, crushers, and heavy-duty DC-driven equipment.

Marine and Offshore Equipment

For propulsion systems, winches, and cranes with DCS drive technology.

Automotive Manufacturing

Employed in paint lines, presses, and robotic arms requiring variable DC control.

Energy and Power

Used in wind tunnel testing setups and generator control in test rigs.

Product Advantages

High Compatibility

Fully compatible with ABB’s DCS500 and DCS600 series, ensuring reliable integration and upgrade flexibility.

Robust Communication

Supports analog and serial interfaces, enabling seamless interaction with PLCs, HMIs, and remote monitoring systems.

Enhanced Diagnostics

Onboard LEDs and built-in self-diagnostics help in quick fault detection and minimal troubleshooting time.

Compact Design

Space-saving form factor allows installation in tight control cabinets.

Industrial Durability

Conformal coating and high-tolerance components ensure long life in harsh industrial conditions.

Upgradeable Firmware

Supports firmware updates for extended functionality and compatibility with new features.

Stabilized Performance

Ensures reliable operation in long production cycles without performance drift.

Service-Friendly

Modular plug-in design makes replacement and servicing simple and efficient.

Frequently Asked Questions (FAQ)

1. What is the main purpose of the SDCS-CON-3A board?

It functions as the control and communication interface for ABB’s DCS 500/600 DC drive systems.

2. Is it compatible with the DCS800 series?

No, the SDCS-CON-3A is designed for the DCS 500 and DCS 600 series only.

3. Can the board be upgraded with new firmware?

Yes, firmware updates can be performed via a serial interface using ABB service tools.

4. Does this board come pre-configured?

No, configuration is done during commissioning through the drive’s user interface or software.

5. What happens if the board fails during operation?

The drive will signal a fault, and the system will either shut down or switch to a safe state.

6. Are diagnostic LEDs available?

Yes, the board features LEDs for visual status and fault indication.

7. Can I use this board in non-ABB drive systems?

No, it is proprietary to ABB DCS 500/600 drive systems and is not compatible with third-party drives.

8. Is it possible to replace the board without recalibrating the whole system?

In many cases, yes. If parameters are stored externally or on EEPROM, system recalibration may not be needed.

9. Does the board have protection against dust or corrosion?

Yes, it is coated with a protective layer to withstand industrial environmental conditions.

10. What kind of diagnostic features are built into the SDCS-CON-3A?

It has onboard status LEDs and supports fault logging via the drive’s monitoring system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...