Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

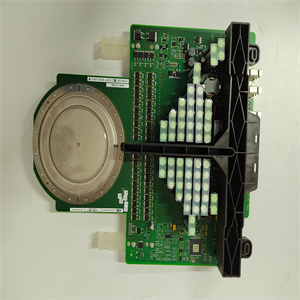

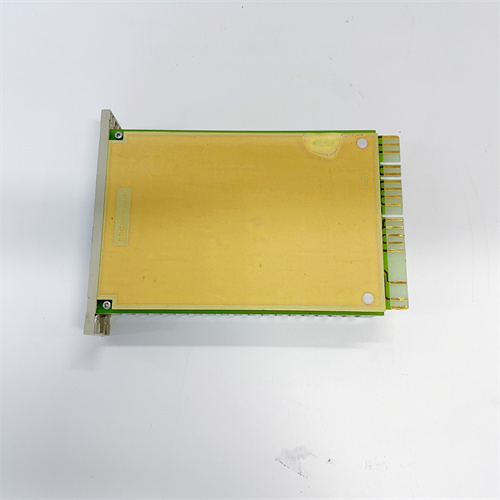

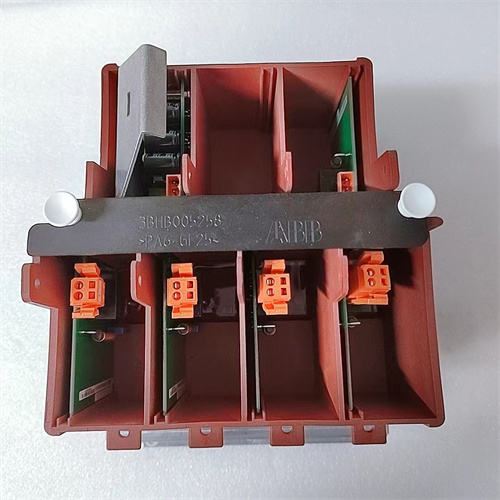

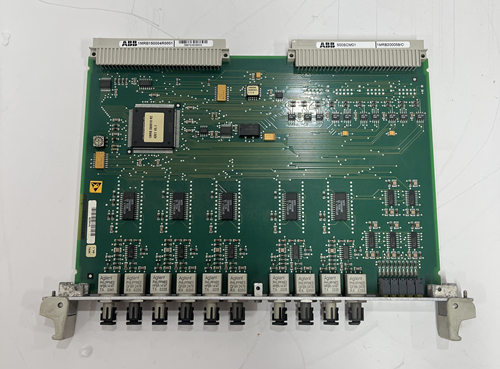

ABB REM610B11HCHR Motor Protection Relay

Manufacturer:ABB

Product Number:REM610B11HCHR

Product Type:Motor Protection Relay

Origin:Sweden (SE)

Dimensions:177 × 177 × 149.3 mm

Weight:3.5 kg

Views:114

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

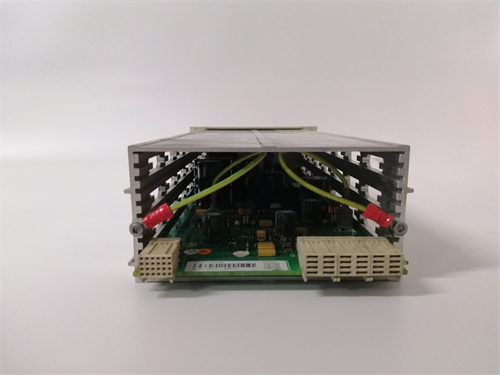

The ABB REM610B11HCHR is a robust and efficient motor protection relay engineered for the protection of asynchronous (induction) motors used in industrial and utility power systems. As part of ABB’s Relion® REM610 series, this specific variant combines the reliability of hardware-based protection with advanced logic capabilities and integration support for supervisory control systems.

Optimized for low and medium-voltage motor applications, the REM610B11HCHR delivers comprehensive protection features such as thermal overload, locked rotor, phase failure, and unbalance detection. Its built-in communication capabilities and event recording functions make it a smart and efficient solution for high-performance motor protection in critical applications.

Product Specifications

| Parameter | Value |

|---|---|

| Model | REM610B11HCHR |

| Relay Type | Motor Protection Relay |

| Supported Motors | Low/Medium voltage asynchronous motors |

| Rated Frequency | 50/60 Hz |

| Rated Current Input | 1 A / 5 A (selectable CT inputs) |

| Current Measurement Range | 0.2 × In to 40 × In |

| Voltage Input | Optional (for undervoltage, overvoltage) |

| Thermal Overload Protection | True RMS-based, IEC/ANSI curves |

| Locked Rotor Protection | Configurable during start and running states |

| Phase Unbalance Protection | Yes, based on negative-sequence current |

| Stator Earth Fault Protection | Yes |

| Phase Reversal Detection | Yes |

| Trip Outputs | 4 binary outputs (user-programmable) |

| Binary Inputs | 6 configurable digital inputs |

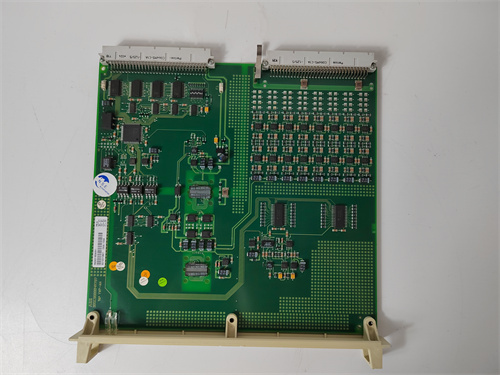

| User Interface | LCD display, 6 LED indicators, keypad |

| Communication Protocols | Modbus RTU, IEC 60870-5-103, optional IEC 61850 |

| Event Recording | 1000+ events, time-stamped |

| Disturbance Recorder | Integrated, 32 samples/cycle |

| Self-supervision | Continuous internal diagnostics |

| Mounting Type | Panel / Flush mount |

| Configuration Software | PCM600 |

| Ingress Protection | IP54 (front), IP20 (rear) |

| Operating Temperature Range | –25°C to +55°C |

| Storage Temperature | –40°C to +70°C |

| Standards Compliance | IEC 60255, CE, RoHS, UL certified |

| Dimensions (H × W × D) | 177 × 177 × 149.3 mm |

| Weight | 3.5 kg |

Product Applications

The REM610B11HCHR motor protection relay is ideal for a wide variety of sectors that rely heavily on electric motors. It is particularly suitable for:

Water treatment and pumping stations

Chemical and petrochemical plants

Power generation and auxiliary systems

Mining and materials handling

Pulp, paper, and packaging industries

HVAC and ventilation systems in large facilities

Food and beverage manufacturing

Oil and gas production fields

Product Advantages

Complete Motor Protection

Offers broad protection coverage: thermal overload, short-circuit, phase loss, unbalance, blocked rotor, and earth fault.

Advanced Communication Capabilities

Supports Modbus and IEC 60870-5-103, with optional IEC 61850, enabling full integration with DCS and SCADA systems.

Built-in Diagnostics and Logging

Advanced event and fault recorders assist with root cause analysis and system maintenance planning.

Flexible Configuration

Protection and logic settings can be customized via PCM600 software or via the intuitive front panel HMI.

Enhanced Safety and Control

With programmable trip logic and dedicated protection stages, it allows precise fault isolation and minimizes system disruption.

User-friendly Interface

Equipped with a clear display and intuitive keypad navigation, allowing for easy access to status, settings, and diagnostics.

Industrial-Grade Reliability

Engineered to withstand industrial environments with robust EMC immunity and mechanical durability.

Compact Yet Powerful

Its compact size simplifies retrofitting in existing panels while maintaining full functionality.

FAQ

Can REM610B11HCHR provide thermal overload protection using both IEC and ANSI curves?

Yes, it allows selection between IEC and ANSI overload curves, tailored for motor protection under various load profiles.

Does the relay detect and trip on locked rotor conditions during start and running?

Absolutely. It offers separate locked rotor detection for startup and for stalled conditions during motor operation.

Is phase unbalance measured using negative-sequence components?

Yes, it uses negative-sequence current calculations to detect unbalance and asymmetry.

How are time delays configured for protection elements?

Time delays can be configured individually for each protection stage through PCM600 or directly via the local HMI.

Can the REM610B11HCHR interface with SCADA systems?

Yes, using Modbus RTU, IEC 60870-5-103, or optional IEC 61850, it integrates seamlessly with SCADA platforms.

Does the REM610B11HCHR support start supervision logic?

Yes, it monitors start duration and frequency, ensuring the motor does not exceed thermal limits.

How does REM610B11HCHR differentiate between inrush current and short circuits?

It uses time-current curve discrimination and optional inrush blocking logic to avoid nuisance tripping.

Can the user configure protection logic using Boolean equations?

Yes, internal logic can be programmed using the graphical logic editor in PCM600 software.

What is the sampling rate for the internal disturbance recorder?

The disturbance recorder samples at 32 samples per cycle, offering detailed waveform capture.

Can the relay operate in environments with high electromagnetic interference?

Yes, it meets rigorous IEC standards for EMC immunity and is designed for high-interference industrial areas.

ABB REM610B11HCHR Motor Protection Relay

Manufacturer:ABB

Product Number:REM610B11HCHR

Product Type:Motor Protection Relay

Origin:Sweden (SE)

Dimensions:177 × 177 × 149.3 mm

Weight:3.5 kg

Views:114

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB REM610B11HCHR is a robust and efficient motor protection relay engineered for the protection of asynchronous (induction) motors used in industrial and utility power systems. As part of ABB’s Relion® REM610 series, this specific variant combines the reliability of hardware-based protection with advanced logic capabilities and integration support for supervisory control systems.

Optimized for low and medium-voltage motor applications, the REM610B11HCHR delivers comprehensive protection features such as thermal overload, locked rotor, phase failure, and unbalance detection. Its built-in communication capabilities and event recording functions make it a smart and efficient solution for high-performance motor protection in critical applications.

Product Specifications

| Parameter | Value |

|---|---|

| Model | REM610B11HCHR |

| Relay Type | Motor Protection Relay |

| Supported Motors | Low/Medium voltage asynchronous motors |

| Rated Frequency | 50/60 Hz |

| Rated Current Input | 1 A / 5 A (selectable CT inputs) |

| Current Measurement Range | 0.2 × In to 40 × In |

| Voltage Input | Optional (for undervoltage, overvoltage) |

| Thermal Overload Protection | True RMS-based, IEC/ANSI curves |

| Locked Rotor Protection | Configurable during start and running states |

| Phase Unbalance Protection | Yes, based on negative-sequence current |

| Stator Earth Fault Protection | Yes |

| Phase Reversal Detection | Yes |

| Trip Outputs | 4 binary outputs (user-programmable) |

| Binary Inputs | 6 configurable digital inputs |

| User Interface | LCD display, 6 LED indicators, keypad |

| Communication Protocols | Modbus RTU, IEC 60870-5-103, optional IEC 61850 |

| Event Recording | 1000+ events, time-stamped |

| Disturbance Recorder | Integrated, 32 samples/cycle |

| Self-supervision | Continuous internal diagnostics |

| Mounting Type | Panel / Flush mount |

| Configuration Software | PCM600 |

| Ingress Protection | IP54 (front), IP20 (rear) |

| Operating Temperature Range | –25°C to +55°C |

| Storage Temperature | –40°C to +70°C |

| Standards Compliance | IEC 60255, CE, RoHS, UL certified |

| Dimensions (H × W × D) | 177 × 177 × 149.3 mm |

| Weight | 3.5 kg |

Product Applications

The REM610B11HCHR motor protection relay is ideal for a wide variety of sectors that rely heavily on electric motors. It is particularly suitable for:

Water treatment and pumping stations

Chemical and petrochemical plants

Power generation and auxiliary systems

Mining and materials handling

Pulp, paper, and packaging industries

HVAC and ventilation systems in large facilities

Food and beverage manufacturing

Oil and gas production fields

Product Advantages

Complete Motor Protection

Offers broad protection coverage: thermal overload, short-circuit, phase loss, unbalance, blocked rotor, and earth fault.

Advanced Communication Capabilities

Supports Modbus and IEC 60870-5-103, with optional IEC 61850, enabling full integration with DCS and SCADA systems.

Built-in Diagnostics and Logging

Advanced event and fault recorders assist with root cause analysis and system maintenance planning.

Flexible Configuration

Protection and logic settings can be customized via PCM600 software or via the intuitive front panel HMI.

Enhanced Safety and Control

With programmable trip logic and dedicated protection stages, it allows precise fault isolation and minimizes system disruption.

User-friendly Interface

Equipped with a clear display and intuitive keypad navigation, allowing for easy access to status, settings, and diagnostics.

Industrial-Grade Reliability

Engineered to withstand industrial environments with robust EMC immunity and mechanical durability.

Compact Yet Powerful

Its compact size simplifies retrofitting in existing panels while maintaining full functionality.

FAQ

Can REM610B11HCHR provide thermal overload protection using both IEC and ANSI curves?

Yes, it allows selection between IEC and ANSI overload curves, tailored for motor protection under various load profiles.

Does the relay detect and trip on locked rotor conditions during start and running?

Absolutely. It offers separate locked rotor detection for startup and for stalled conditions during motor operation.

Is phase unbalance measured using negative-sequence components?

Yes, it uses negative-sequence current calculations to detect unbalance and asymmetry.

How are time delays configured for protection elements?

Time delays can be configured individually for each protection stage through PCM600 or directly via the local HMI.

Can the REM610B11HCHR interface with SCADA systems?

Yes, using Modbus RTU, IEC 60870-5-103, or optional IEC 61850, it integrates seamlessly with SCADA platforms.

Does the REM610B11HCHR support start supervision logic?

Yes, it monitors start duration and frequency, ensuring the motor does not exceed thermal limits.

How does REM610B11HCHR differentiate between inrush current and short circuits?

It uses time-current curve discrimination and optional inrush blocking logic to avoid nuisance tripping.

Can the user configure protection logic using Boolean equations?

Yes, internal logic can be programmed using the graphical logic editor in PCM600 software.

What is the sampling rate for the internal disturbance recorder?

The disturbance recorder samples at 32 samples per cycle, offering detailed waveform capture.

Can the relay operate in environments with high electromagnetic interference?

Yes, it meets rigorous IEC standards for EMC immunity and is designed for high-interference industrial areas.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...