Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

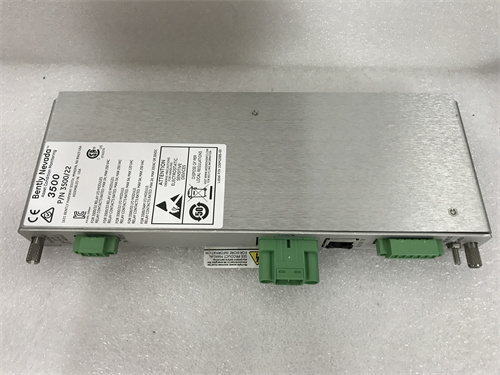

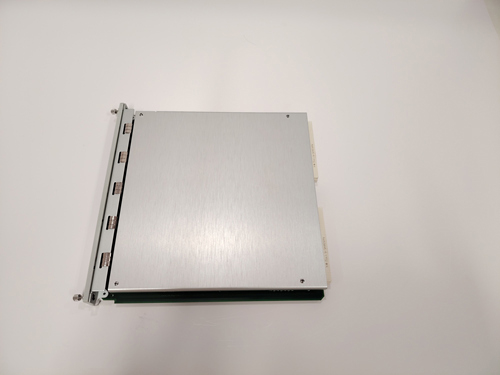

Bently Nevada 3500/44M 176449-03 Aeroderivitive GT Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3500/44M 176449-03

Product Type:Aeroderivitive GT Vibration Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/44M 176449-03 Aeroderivitive GT Vibration Monitor is a specialized monitoring module designed to provide accurate and reliable vibration measurement for aeroderivative gas turbines. It plays a critical role in machinery protection by detecting abnormal vibration patterns that could indicate mechanical faults, enabling preventive maintenance and minimizing unplanned downtime. As part of the 3500 Series Machinery Protection System, it ensures seamless integration and consistent performance in demanding industrial environments.

Key Features

Specialized design for aeroderivative gas turbine vibration monitoring

Four-channel input for independent vibration measurements

Real-time analysis with continuous monitoring capabilities

Full integration with the Bently Nevada 3500 rack system

Robust design to withstand harsh industrial operating conditions

Technical Specifications

| Item | Description |

|---|---|

| Module Type | Aeroderivitive GT Vibration Monitor |

| Model Number | 3500/44M |

| Part Number | 176449-03 |

| Channels | 4 |

| Measurement Type | Vibration |

| Input Signal | Proximity probes and seismic transducers |

| Power Supply | From 3500 rack |

| Communication | Integrated with 3500 rack system |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | Rack-mounted in 3500 Series frame |

Industry Applications

-

Aeroderivative gas turbine condition monitoring

-

Oil and gas production facilities

-

Power generation plants

-

Petrochemical and refinery operations

-

Industrial rotating machinery protection

Frequently Asked Questions (FAQ)

Q1: What is the main application of the 3500/44M?

It is used for precise vibration monitoring of aeroderivative gas turbines to ensure safe and efficient operation.

Q2: How many vibration channels does the module have?

It has four independent channels.

Q3: What types of sensors are supported?

It supports both proximity probes and seismic transducers.

Q4: Is it compatible with all 3500 racks?

Yes, it is fully compatible with Bently Nevada 3500 Series racks.

Q5: What is the operating temperature range?

The operating range is from -30°C to +65°C.

Q6: Does it require an external power source?

No, it receives power directly from the 3500 rack.

Q7: Can it be used for non-aeroderivative turbine machinery?

Yes, but it is specifically optimized for aeroderivative turbine applications.

Q8: Is the monitoring continuous?

Yes, it provides real-time continuous vibration monitoring.

Q9: What is the part number?

The part number is 176449-03.

Q10: What is the weight of the module?

It weighs approximately 0.91 kg.

Bently Nevada 3500/44M 176449-03 Aeroderivitive GT Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3500/44M 176449-03

Product Type:Aeroderivitive GT Vibration Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/44M 176449-03 Aeroderivitive GT Vibration Monitor is a specialized monitoring module designed to provide accurate and reliable vibration measurement for aeroderivative gas turbines. It plays a critical role in machinery protection by detecting abnormal vibration patterns that could indicate mechanical faults, enabling preventive maintenance and minimizing unplanned downtime. As part of the 3500 Series Machinery Protection System, it ensures seamless integration and consistent performance in demanding industrial environments.

Key Features

Specialized design for aeroderivative gas turbine vibration monitoring

Four-channel input for independent vibration measurements

Real-time analysis with continuous monitoring capabilities

Full integration with the Bently Nevada 3500 rack system

Robust design to withstand harsh industrial operating conditions

Technical Specifications

| Item | Description |

|---|---|

| Module Type | Aeroderivitive GT Vibration Monitor |

| Model Number | 3500/44M |

| Part Number | 176449-03 |

| Channels | 4 |

| Measurement Type | Vibration |

| Input Signal | Proximity probes and seismic transducers |

| Power Supply | From 3500 rack |

| Communication | Integrated with 3500 rack system |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | Rack-mounted in 3500 Series frame |

Industry Applications

-

Aeroderivative gas turbine condition monitoring

-

Oil and gas production facilities

-

Power generation plants

-

Petrochemical and refinery operations

-

Industrial rotating machinery protection

Frequently Asked Questions (FAQ)

Q1: What is the main application of the 3500/44M?

It is used for precise vibration monitoring of aeroderivative gas turbines to ensure safe and efficient operation.

Q2: How many vibration channels does the module have?

It has four independent channels.

Q3: What types of sensors are supported?

It supports both proximity probes and seismic transducers.

Q4: Is it compatible with all 3500 racks?

Yes, it is fully compatible with Bently Nevada 3500 Series racks.

Q5: What is the operating temperature range?

The operating range is from -30°C to +65°C.

Q6: Does it require an external power source?

No, it receives power directly from the 3500 rack.

Q7: Can it be used for non-aeroderivative turbine machinery?

Yes, but it is specifically optimized for aeroderivative turbine applications.

Q8: Is the monitoring continuous?

Yes, it provides real-time continuous vibration monitoring.

Q9: What is the part number?

The part number is 176449-03.

Q10: What is the weight of the module?

It weighs approximately 0.91 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...