Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

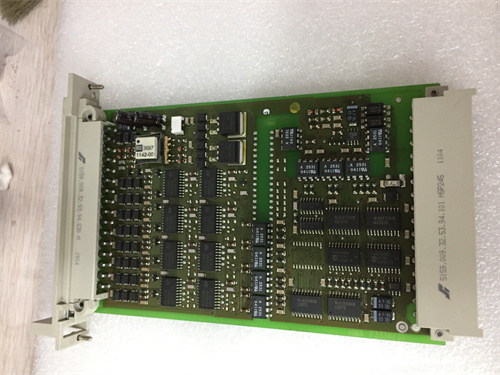

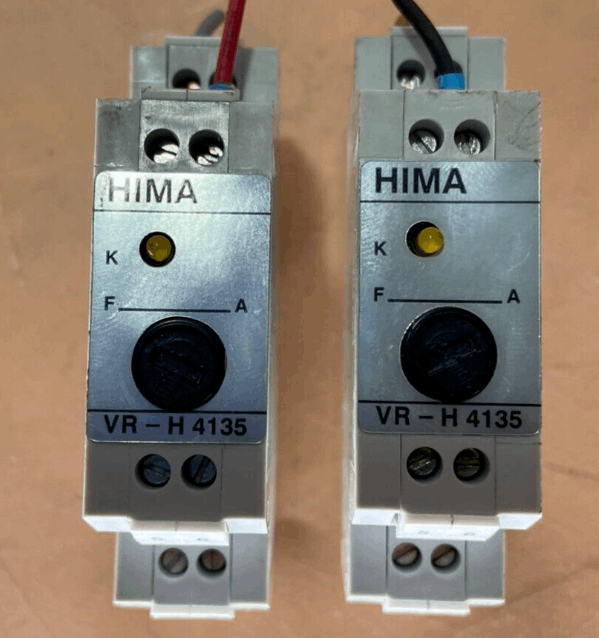

Hima F6101 Safety Related System Module

Manufacturer:HIMA

Product Number:F6101

Product Type:Safety Related System Module

Origin:Germany

Dimensions:216 x 130 x 30 mm

Weight:0.2 kg

Views:105

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

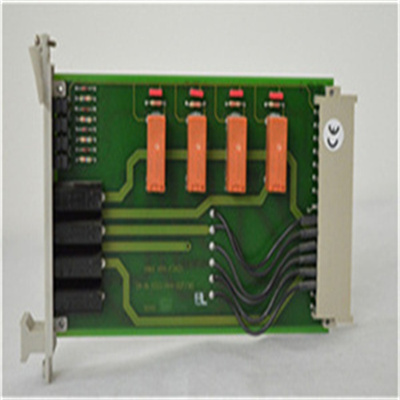

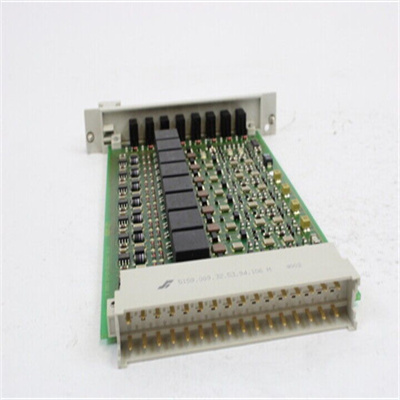

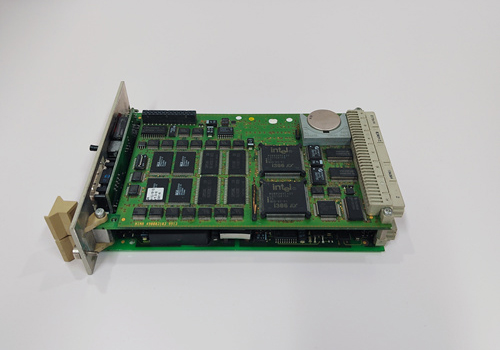

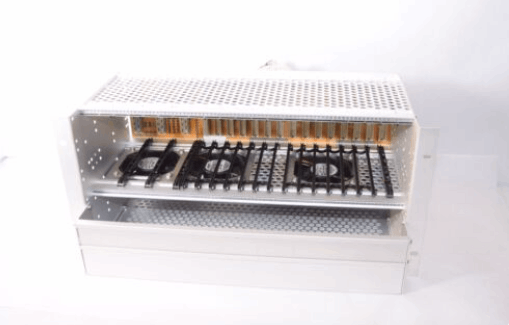

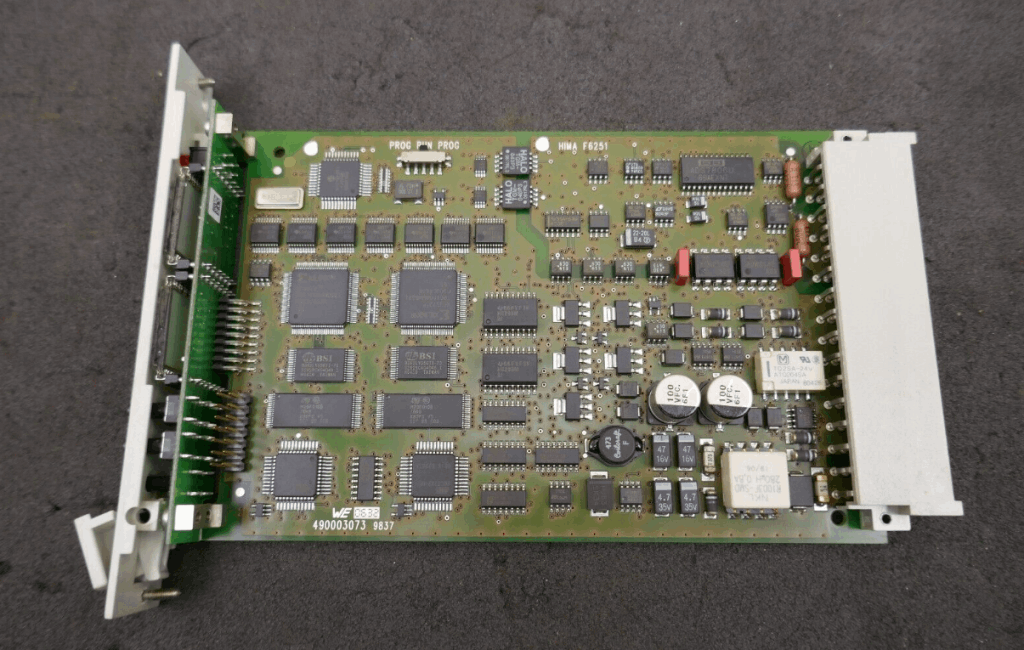

The HIMA F6101 Safety Related System Module is a critical component in the HIMA HIMax and HIQuad safety system families, specifically engineered for use in applications where functional safety, high availability, and fail-safe operation are paramount. Designed and manufactured by HIMA Paul Hildebrandt GmbH, a globally recognized leader in industrial safety automation, the F6101 module plays a pivotal role in logic execution within Safety Instrumented Systems (SIS).

This module is suitable for implementation in process industries such as oil & gas, petrochemicals, power generation, chemical plants, and pharmaceuticals, where compliance with international safety standards such as IEC 61508 and SIL 3 is mandatory. The F6101 ensures that any detected system fault will safely bring the process to a defined state, thereby protecting personnel, environment, and assets.

Robust in design, with high electromagnetic compatibility and immunity to industrial interference, the F6101 is built to perform reliably in the most demanding industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | F6101 |

| Manufacturer | HIMA Paul Hildebrandt GmbH |

| Function | Safety-Related System Logic Module |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508 compliant) |

| Redundancy | Supports redundant operation |

| Number of Channels | Configurable via system architecture |

| CPU Type | High-speed logic processor |

| Communication Interface | Proprietary HIMA system bus |

| Diagnostics | Integrated self-diagnostics and system health monitoring |

| Power Supply Voltage | 24 V DC (redundant power supply possible) |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95%, non-condensing |

| Shock/Vibration Resistance | IEC 60068-2-6 / IEC 60068-2-27 compliant |

| EMC Compliance | EN 61000-6-2 / EN 61000-6-4 |

| Mounting | 19″ rack mount / DIN rail (depends on system configuration) |

| Dimensions (H x W x D) | 216 x 130 x 30 mm |

| Weight | 0.2 kg |

Product Applications

The HIMA F6101 is widely deployed in functional safety systems, especially where logic execution and decision-making processes must be both deterministic and fail-safe. Common applications include:

Emergency Shutdown Systems (ESD)

Fire and Gas Systems (F&G)

High-Integrity Pressure Protection Systems (HIPPS)

Turbomachinery Control

Pipeline Monitoring and Valve Interlocks

In all these applications, the F6101 module executes the programmed safety logic and ensures the safe state activation in the event of abnormal conditions or system errors.

Product Advantages

Certified SIL 3 Compliance

Ensures reliable operation under safety-critical conditions in accordance with IEC 61508.

High Reliability and Availability

Designed for use in redundant architectures to avoid single-point failures.

Fast Logic Processing

Capable of real-time response to safety events with deterministic execution.

Modular and Scalable

Easily integrated into larger HIMA safety systems such as HIMax or HIQuad.

Advanced Diagnostics

In-built diagnostic features allow real-time health monitoring of the system and predictive maintenance.

Long Service Life

Industrial-grade design ensures long operational life with minimal maintenance.

Seamless Integration

Compatible with other HIMA modules and engineering tools, enabling comprehensive safety solution development.

FAQ

What is the primary role of the F6101 module in a safety system?

It acts as the central logic processing unit in safety-related control applications, executing SIL 3-level safety functions.

Is the F6101 module hot-swappable?

Yes, the module supports hot-swapping when installed in a redundant system without interrupting operations.

Can the F6101 be used in a non-redundant system?

Yes, while it supports redundancy, it can also function as a standalone unit in smaller systems.

What engineering tools are used to configure the F6101?

HIMA’s ELOP II or SILworX programming environments are typically used.

Does this module support integration with DCS systems?

Yes, via communication modules such as Profibus DP, Modbus TCP, or OPC interfaces.

How often does the F6101 require maintenance or calibration?

Regular diagnostics are built-in, and maintenance is typically limited to visual inspections and annual tests.

Is the module certified for use in hazardous areas?

The module can be installed in systems that are certified for ATEX or IECEx zones, depending on enclosure and installation.

What happens if the module fails?

In redundant setups, failover occurs without downtime. In standalone mode, the system will revert to a safe state.

What is the life expectancy of the F6101 module?

Typically over 15 years under normal operating conditions.

Can the F6101 be used in retrofit or upgrade projects?

Yes, it is frequently used in both new installations and upgrades of legacy HIMA systems.

Hima F6101 Safety Related System Module

Manufacturer:HIMA

Product Number:F6101

Product Type:Safety Related System Module

Origin:Germany

Dimensions:216 x 130 x 30 mm

Weight:0.2 kg

Views:105

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F6101 Safety Related System Module is a critical component in the HIMA HIMax and HIQuad safety system families, specifically engineered for use in applications where functional safety, high availability, and fail-safe operation are paramount. Designed and manufactured by HIMA Paul Hildebrandt GmbH, a globally recognized leader in industrial safety automation, the F6101 module plays a pivotal role in logic execution within Safety Instrumented Systems (SIS).

This module is suitable for implementation in process industries such as oil & gas, petrochemicals, power generation, chemical plants, and pharmaceuticals, where compliance with international safety standards such as IEC 61508 and SIL 3 is mandatory. The F6101 ensures that any detected system fault will safely bring the process to a defined state, thereby protecting personnel, environment, and assets.

Robust in design, with high electromagnetic compatibility and immunity to industrial interference, the F6101 is built to perform reliably in the most demanding industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | F6101 |

| Manufacturer | HIMA Paul Hildebrandt GmbH |

| Function | Safety-Related System Logic Module |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508 compliant) |

| Redundancy | Supports redundant operation |

| Number of Channels | Configurable via system architecture |

| CPU Type | High-speed logic processor |

| Communication Interface | Proprietary HIMA system bus |

| Diagnostics | Integrated self-diagnostics and system health monitoring |

| Power Supply Voltage | 24 V DC (redundant power supply possible) |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95%, non-condensing |

| Shock/Vibration Resistance | IEC 60068-2-6 / IEC 60068-2-27 compliant |

| EMC Compliance | EN 61000-6-2 / EN 61000-6-4 |

| Mounting | 19″ rack mount / DIN rail (depends on system configuration) |

| Dimensions (H x W x D) | 216 x 130 x 30 mm |

| Weight | 0.2 kg |

Product Applications

The HIMA F6101 is widely deployed in functional safety systems, especially where logic execution and decision-making processes must be both deterministic and fail-safe. Common applications include:

Emergency Shutdown Systems (ESD)

Fire and Gas Systems (F&G)

High-Integrity Pressure Protection Systems (HIPPS)

Turbomachinery Control

Pipeline Monitoring and Valve Interlocks

In all these applications, the F6101 module executes the programmed safety logic and ensures the safe state activation in the event of abnormal conditions or system errors.

Product Advantages

Certified SIL 3 Compliance

Ensures reliable operation under safety-critical conditions in accordance with IEC 61508.

High Reliability and Availability

Designed for use in redundant architectures to avoid single-point failures.

Fast Logic Processing

Capable of real-time response to safety events with deterministic execution.

Modular and Scalable

Easily integrated into larger HIMA safety systems such as HIMax or HIQuad.

Advanced Diagnostics

In-built diagnostic features allow real-time health monitoring of the system and predictive maintenance.

Long Service Life

Industrial-grade design ensures long operational life with minimal maintenance.

Seamless Integration

Compatible with other HIMA modules and engineering tools, enabling comprehensive safety solution development.

FAQ

What is the primary role of the F6101 module in a safety system?

It acts as the central logic processing unit in safety-related control applications, executing SIL 3-level safety functions.

Is the F6101 module hot-swappable?

Yes, the module supports hot-swapping when installed in a redundant system without interrupting operations.

Can the F6101 be used in a non-redundant system?

Yes, while it supports redundancy, it can also function as a standalone unit in smaller systems.

What engineering tools are used to configure the F6101?

HIMA’s ELOP II or SILworX programming environments are typically used.

Does this module support integration with DCS systems?

Yes, via communication modules such as Profibus DP, Modbus TCP, or OPC interfaces.

How often does the F6101 require maintenance or calibration?

Regular diagnostics are built-in, and maintenance is typically limited to visual inspections and annual tests.

Is the module certified for use in hazardous areas?

The module can be installed in systems that are certified for ATEX or IECEx zones, depending on enclosure and installation.

What happens if the module fails?

In redundant setups, failover occurs without downtime. In standalone mode, the system will revert to a safe state.

What is the life expectancy of the F6101 module?

Typically over 15 years under normal operating conditions.

Can the F6101 be used in retrofit or upgrade projects?

Yes, it is frequently used in both new installations and upgrades of legacy HIMA systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...