Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

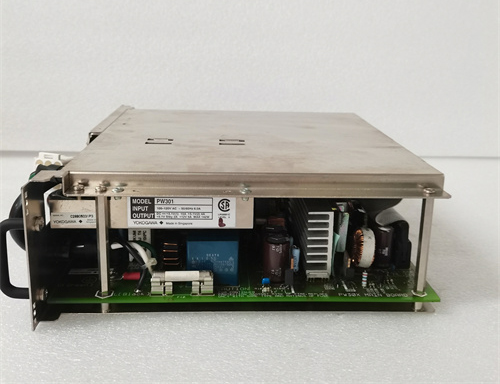

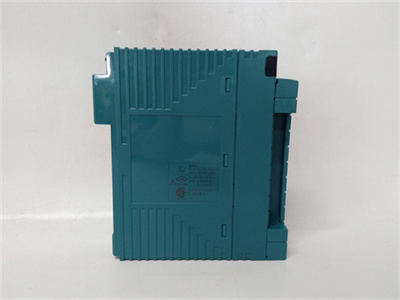

Yokogawa YS170-012 Programmable Controller

Manufacturer:Yokogawa

Product Number:YS170-012

Product Type:Programmable Controller

Origin:Japan

Dimensions:70 x 145 x 293 mm

Weight:1.6 kg

Views:84

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

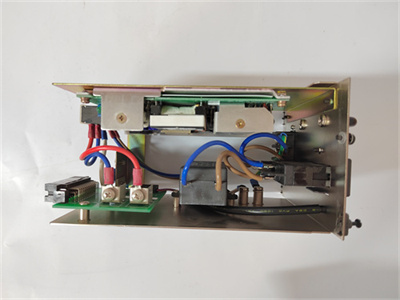

The Yokogawa YS170-012 Programmable Controller is a powerful and highly dependable device engineered for industrial process control and automation. It belongs to the renowned YS100 series, known for delivering reliable analog and digital control in a compact, panel-mounted format. The YS170-012 is especially valued in industries where stability, precision, and flexibility are critical, such as chemical processing, power generation, water treatment, and oil refining.

Unlike standard PID controllers, the YS170-012 offers programmable logic control (PLC) features in a controller form factor, providing users with advanced control strategies, multiple I/O functions, and user-defined operation sequences. Its bright, clear front panel display and robust signal handling make it suitable for both new system installations and upgrades of legacy systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model | YS170-012 |

| Series | YS100 Series |

| Function | Programmable Controller (PID + Logic Capabilities) |

| Input Signal | Universal (DC current, voltage, thermocouple, RTD) |

| Control Loops | 1 loop (programmable) |

| Control Modes | PID, ON/OFF, Manual, Auto |

| Output Signal | 4–20 mA DC, Relay contact, Pulse output |

| Power Supply | 100 to 240 V AC, 50/60 Hz |

| Power Consumption | Approx. 20 VA |

| Display Type | Vacuum fluorescent (VFD) display |

| Display Resolution | 5 digits + bar graph |

| Memory Backup | Non-volatile memory (EEPROM) |

| Mounting Style | Panel-mount (flush mount) |

| Communication | RS-485 (Modbus RTU optional) |

| Operating Temperature | 0°C to 50°C |

| Humidity Range | 10% to 90% RH (non-condensing) |

| Enclosure Rating | IP54 (front panel only) |

| Certifications | CE, CSA, UL |

| Dimensions (H × W × D) | 70 x 145 x 293 mm |

| Weight | 1.6 kg |

Product Applications

Chemical Manufacturing

Provides precise temperature and flow control in batch or continuous reactors, improving yield and safety.

Power Generation

Controls boiler feedwater, fuel gas regulation, and turbine speed in steam and gas turbine systems.

Pharmaceutical Processing

Used in sterile environments for exact process control in mixers, fermentation tanks, and temperature baths.

Water and Wastewater Treatment

Manages pump control, dosing systems, and aeration processes for municipal and industrial treatment plants.

Food & Beverage Industry

Supports temperature and timing control in ovens, fermentation chambers, and pasteurization units.

Oil & Gas Facilities

Regulates separator temperature, flow control, and tank level in upstream and midstream operations.

Product Advantages

Advanced Programmability

Enables custom logic design within the controller, eliminating the need for separate PLCs in smaller systems.

Integrated PID Control

Combines high-performance PID with logic operations, reducing system complexity.

Clear Visual Interface

High-visibility VFD screen with bar graph and numeric display improves usability and operator awareness.

Long-Term Memory Backup

Stores user programs and settings safely without batteries, thanks to EEPROM technology.

Flexible Input/Output Options

Compatible with a wide range of analog and digital signals for diverse application environments.

Easy Panel Integration

Compact panel-mount design ensures seamless installation in control cabinets or operator stations.

Field-Proven Reliability

Widely used in process industries for over a decade, known for stable performance and long service life.

-

Optional RS-485 support allows easy integration into SCADA or DCS environments.

Frequently Asked Questions (FAQ)

What type of control modes are supported in YS170-012?

It supports PID, ON/OFF, manual, and auto modes for flexible process management.

Can I create custom control logic using this controller?

Yes, the YS170-012 includes programmable logic capabilities for user-defined control sequences.

What types of input signals are accepted?

It supports universal inputs, including thermocouples, RTDs, DC current, and DC voltage.

Is this controller suitable for hazardous environments?

While not rated for explosion-proof zones, it is CE and UL certified for general industrial use.

Does the unit support communication with other devices?

Yes, optional Modbus RTU via RS-485 is available for integration with external systems.

What happens during a power outage?

All user settings and programs are retained in non-volatile memory, eliminating the need for reconfiguration.

Can this controller be used for motor control?

Yes, it can control motors through relay or analog output in combination with external devices like VFDs.

Is this product a drop-in replacement for older YS series controllers?

Yes, the dimensions and wiring are designed for backward compatibility with earlier Yokogawa units.

Does the YS170-012 support remote operation?

Through RS-485 communication, it can be monitored and configured remotely via SCADA/DCS.

What tools are needed for programming the unit?

Programming is performed via the front panel interface or through PC configuration software (optional).

Yokogawa YS170-012 Programmable Controller

Manufacturer:Yokogawa

Product Number:YS170-012

Product Type:Programmable Controller

Origin:Japan

Dimensions:70 x 145 x 293 mm

Weight:1.6 kg

Views:84

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa YS170-012 Programmable Controller is a powerful and highly dependable device engineered for industrial process control and automation. It belongs to the renowned YS100 series, known for delivering reliable analog and digital control in a compact, panel-mounted format. The YS170-012 is especially valued in industries where stability, precision, and flexibility are critical, such as chemical processing, power generation, water treatment, and oil refining.

Unlike standard PID controllers, the YS170-012 offers programmable logic control (PLC) features in a controller form factor, providing users with advanced control strategies, multiple I/O functions, and user-defined operation sequences. Its bright, clear front panel display and robust signal handling make it suitable for both new system installations and upgrades of legacy systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model | YS170-012 |

| Series | YS100 Series |

| Function | Programmable Controller (PID + Logic Capabilities) |

| Input Signal | Universal (DC current, voltage, thermocouple, RTD) |

| Control Loops | 1 loop (programmable) |

| Control Modes | PID, ON/OFF, Manual, Auto |

| Output Signal | 4–20 mA DC, Relay contact, Pulse output |

| Power Supply | 100 to 240 V AC, 50/60 Hz |

| Power Consumption | Approx. 20 VA |

| Display Type | Vacuum fluorescent (VFD) display |

| Display Resolution | 5 digits + bar graph |

| Memory Backup | Non-volatile memory (EEPROM) |

| Mounting Style | Panel-mount (flush mount) |

| Communication | RS-485 (Modbus RTU optional) |

| Operating Temperature | 0°C to 50°C |

| Humidity Range | 10% to 90% RH (non-condensing) |

| Enclosure Rating | IP54 (front panel only) |

| Certifications | CE, CSA, UL |

| Dimensions (H × W × D) | 70 x 145 x 293 mm |

| Weight | 1.6 kg |

Product Applications

Chemical Manufacturing

Provides precise temperature and flow control in batch or continuous reactors, improving yield and safety.

Power Generation

Controls boiler feedwater, fuel gas regulation, and turbine speed in steam and gas turbine systems.

Pharmaceutical Processing

Used in sterile environments for exact process control in mixers, fermentation tanks, and temperature baths.

Water and Wastewater Treatment

Manages pump control, dosing systems, and aeration processes for municipal and industrial treatment plants.

Food & Beverage Industry

Supports temperature and timing control in ovens, fermentation chambers, and pasteurization units.

Oil & Gas Facilities

Regulates separator temperature, flow control, and tank level in upstream and midstream operations.

Product Advantages

Advanced Programmability

Enables custom logic design within the controller, eliminating the need for separate PLCs in smaller systems.

Integrated PID Control

Combines high-performance PID with logic operations, reducing system complexity.

Clear Visual Interface

High-visibility VFD screen with bar graph and numeric display improves usability and operator awareness.

Long-Term Memory Backup

Stores user programs and settings safely without batteries, thanks to EEPROM technology.

Flexible Input/Output Options

Compatible with a wide range of analog and digital signals for diverse application environments.

Easy Panel Integration

Compact panel-mount design ensures seamless installation in control cabinets or operator stations.

Field-Proven Reliability

Widely used in process industries for over a decade, known for stable performance and long service life.

-

Optional RS-485 support allows easy integration into SCADA or DCS environments.

Frequently Asked Questions (FAQ)

What type of control modes are supported in YS170-012?

It supports PID, ON/OFF, manual, and auto modes for flexible process management.

Can I create custom control logic using this controller?

Yes, the YS170-012 includes programmable logic capabilities for user-defined control sequences.

What types of input signals are accepted?

It supports universal inputs, including thermocouples, RTDs, DC current, and DC voltage.

Is this controller suitable for hazardous environments?

While not rated for explosion-proof zones, it is CE and UL certified for general industrial use.

Does the unit support communication with other devices?

Yes, optional Modbus RTU via RS-485 is available for integration with external systems.

What happens during a power outage?

All user settings and programs are retained in non-volatile memory, eliminating the need for reconfiguration.

Can this controller be used for motor control?

Yes, it can control motors through relay or analog output in combination with external devices like VFDs.

Is this product a drop-in replacement for older YS series controllers?

Yes, the dimensions and wiring are designed for backward compatibility with earlier Yokogawa units.

Does the YS170-012 support remote operation?

Through RS-485 communication, it can be monitored and configured remotely via SCADA/DCS.

What tools are needed for programming the unit?

Programming is performed via the front panel interface or through PC configuration software (optional).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...