Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

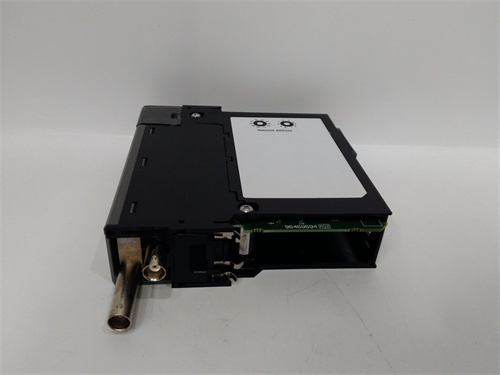

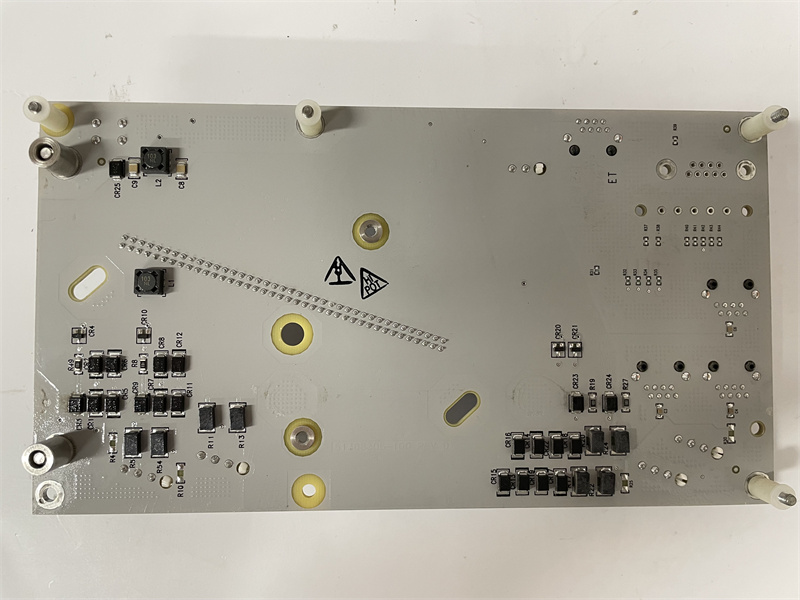

Honeywell 621-0022 Isolated Analog Input Module

Manufacturer:Honeywell

Product Number:621-0022

Product Type:Isolated Analog Input Module

Origin:USA

Dimensions:33 x 274 x 171 mm

Weight:0.68 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

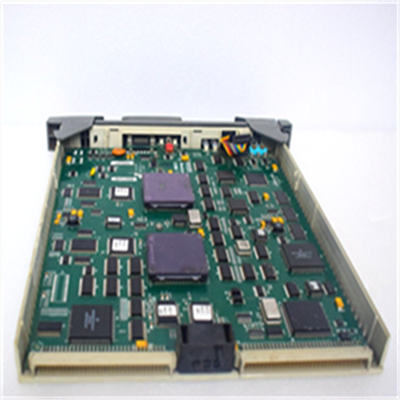

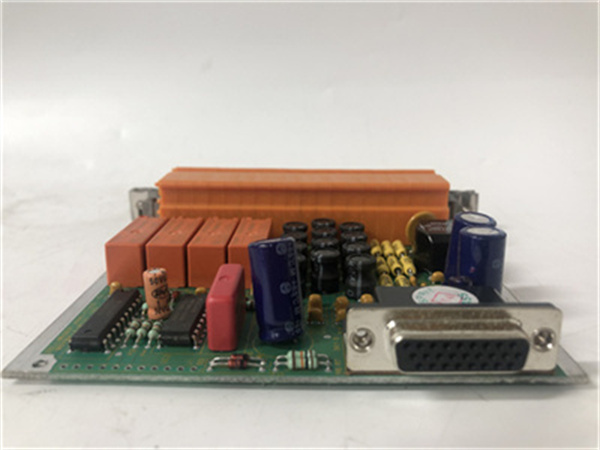

The Honeywell 621-0022 is a high-performance Isolated Analog Input Module designed for Honeywell’s TDC 2000/3000 and PlantScape control systems. As part of Honeywell’s robust control system architecture, this module plays a crucial role in process automation, offering accurate and noise-resistant analog signal acquisition.

The 621-0022 module ensures safe and precise transmission of analog signals from field devices, such as pressure transmitters, temperature sensors, and flow meters, into the central control system. Its isolation capability prevents electrical interference, ensuring the integrity and reliability of data acquisition in critical industrial environments.

This module supports multiple analog signal types (e.g., 4–20 mA, 0–10 V) and is optimized for use in mission-critical applications such as chemical plants, oil & gas facilities, and energy production systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 621-0022 |

| Type | Isolated Analog Input Module |

| Signal Type | Analog (e.g., 4–20 mA, 0–10 V) |

| Number of Channels | 8 analog input channels |

| Input Isolation | Optical/electrical isolation per channel |

| Resolution | 12-bit or better (depends on system config) |

| Input Range | Configurable, typically ±10V or 0–20mA |

| Accuracy | ±0.1% of full scale |

| Power Consumption | Approx. 3W |

| Diagnostics | Internal diagnostics and fault detection |

| Operating Temperature Range | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

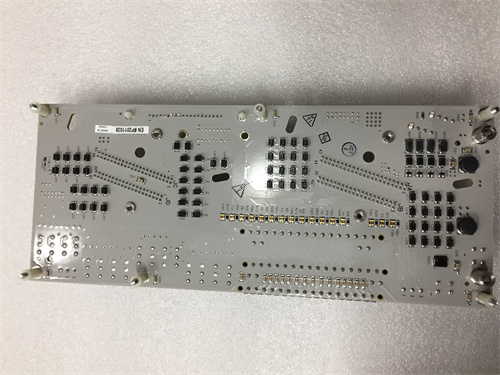

| Mounting | DIN-rail or backplane slot |

| Dimensions (W x H x D) | 33 x 274 x 171 mm |

| Weight | 0.68 kg |

| Compliance | CE, RoHS, ISA, UL certified |

Applications

The Honeywell 621-0022 module is engineered for critical industrial and manufacturing processes where reliable analog signal acquisition is required. Common application scenarios include:

Chemical and Petrochemical Plants

Reliable measurement of process variables like flow, temperature, and pressure.

Oil and Gas Industry

Data acquisition from field instrumentation in upstream and downstream operations.

Power Generation Plants

Monitoring of analog parameters in turbines, boilers, and generators.

Water and Wastewater Management

Measuring levels, flow rates, and water quality indicators.

Pharmaceutical Manufacturing

Accurate and isolated signal acquisition in cleanroom environments.

Food & Beverage Processing

Monitoring temperature and pressure during critical process stages.

Key Advantages

Electrical Isolation

Each channel is isolated to eliminate ground loops and reduce noise, ensuring accurate readings.

High Reliability

Designed for demanding industrial environments with robust diagnostics and fault detection.

Flexible Signal Support

Compatible with various analog signals (voltage and current), supporting diverse sensor types.

Easy Integration

Seamless compatibility with Honeywell DCS systems like TDC 2000, TDC 3000, and PlantScape.

Compact Design

Small footprint allows for efficient installation in tight cabinet spaces.

Field-Proven Performance

Widely adopted in global industrial automation installations with proven long-term reliability.

Frequently Asked Questions (FAQ)

What signal types does the 621-0022 support?

It supports both voltage (e.g., 0–10V) and current (e.g., 4–20mA) analog input signals.

Is each input channel isolated?

Yes, each analog input channel features electrical isolation to prevent ground loops and noise.

Can the 621-0022 be used in hazardous areas?

It should be used with proper intrinsic safety barriers or certified enclosures for hazardous zones.

What Honeywell systems are compatible with this module?

It integrates seamlessly with Honeywell’s TDC 2000, TDC 3000, and PlantScape DCS platforms.

Does it have onboard diagnostics?

Yes, the module includes fault detection and internal diagnostics to support maintenance.

What is the typical accuracy of this module?

It offers a typical accuracy of ±0.1% of full scale.

How many channels does it provide?

The 621-0022 provides 8 isolated analog input channels.

What installation options are available?

It can be mounted via DIN rail or inserted into a backplane slot.

Is calibration required for each channel?

Factory calibration is provided, but periodic calibration may be required depending on process needs.

What kind of isolation is used?

Typically, optical or transformer-based isolation techniques are used to ensure signal integrity.

Honeywell 621-0022 Isolated Analog Input Module

Manufacturer:Honeywell

Product Number:621-0022

Product Type:Isolated Analog Input Module

Origin:USA

Dimensions:33 x 274 x 171 mm

Weight:0.68 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-0022 is a high-performance Isolated Analog Input Module designed for Honeywell’s TDC 2000/3000 and PlantScape control systems. As part of Honeywell’s robust control system architecture, this module plays a crucial role in process automation, offering accurate and noise-resistant analog signal acquisition.

The 621-0022 module ensures safe and precise transmission of analog signals from field devices, such as pressure transmitters, temperature sensors, and flow meters, into the central control system. Its isolation capability prevents electrical interference, ensuring the integrity and reliability of data acquisition in critical industrial environments.

This module supports multiple analog signal types (e.g., 4–20 mA, 0–10 V) and is optimized for use in mission-critical applications such as chemical plants, oil & gas facilities, and energy production systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 621-0022 |

| Type | Isolated Analog Input Module |

| Signal Type | Analog (e.g., 4–20 mA, 0–10 V) |

| Number of Channels | 8 analog input channels |

| Input Isolation | Optical/electrical isolation per channel |

| Resolution | 12-bit or better (depends on system config) |

| Input Range | Configurable, typically ±10V or 0–20mA |

| Accuracy | ±0.1% of full scale |

| Power Consumption | Approx. 3W |

| Diagnostics | Internal diagnostics and fault detection |

| Operating Temperature Range | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

| Mounting | DIN-rail or backplane slot |

| Dimensions (W x H x D) | 33 x 274 x 171 mm |

| Weight | 0.68 kg |

| Compliance | CE, RoHS, ISA, UL certified |

Applications

The Honeywell 621-0022 module is engineered for critical industrial and manufacturing processes where reliable analog signal acquisition is required. Common application scenarios include:

Chemical and Petrochemical Plants

Reliable measurement of process variables like flow, temperature, and pressure.

Oil and Gas Industry

Data acquisition from field instrumentation in upstream and downstream operations.

Power Generation Plants

Monitoring of analog parameters in turbines, boilers, and generators.

Water and Wastewater Management

Measuring levels, flow rates, and water quality indicators.

Pharmaceutical Manufacturing

Accurate and isolated signal acquisition in cleanroom environments.

Food & Beverage Processing

Monitoring temperature and pressure during critical process stages.

Key Advantages

Electrical Isolation

Each channel is isolated to eliminate ground loops and reduce noise, ensuring accurate readings.

High Reliability

Designed for demanding industrial environments with robust diagnostics and fault detection.

Flexible Signal Support

Compatible with various analog signals (voltage and current), supporting diverse sensor types.

Easy Integration

Seamless compatibility with Honeywell DCS systems like TDC 2000, TDC 3000, and PlantScape.

Compact Design

Small footprint allows for efficient installation in tight cabinet spaces.

Field-Proven Performance

Widely adopted in global industrial automation installations with proven long-term reliability.

Frequently Asked Questions (FAQ)

What signal types does the 621-0022 support?

It supports both voltage (e.g., 0–10V) and current (e.g., 4–20mA) analog input signals.

Is each input channel isolated?

Yes, each analog input channel features electrical isolation to prevent ground loops and noise.

Can the 621-0022 be used in hazardous areas?

It should be used with proper intrinsic safety barriers or certified enclosures for hazardous zones.

What Honeywell systems are compatible with this module?

It integrates seamlessly with Honeywell’s TDC 2000, TDC 3000, and PlantScape DCS platforms.

Does it have onboard diagnostics?

Yes, the module includes fault detection and internal diagnostics to support maintenance.

What is the typical accuracy of this module?

It offers a typical accuracy of ±0.1% of full scale.

How many channels does it provide?

The 621-0022 provides 8 isolated analog input channels.

What installation options are available?

It can be mounted via DIN rail or inserted into a backplane slot.

Is calibration required for each channel?

Factory calibration is provided, but periodic calibration may be required depending on process needs.

What kind of isolation is used?

Typically, optical or transformer-based isolation techniques are used to ensure signal integrity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...