FOXBORO FBM230 Detailed Introduction

The FBM230 module is produced by Foxboro and is designed for industrial automation systems.It provides a serial interface between a single-port field I/O device and the EcoStruxure™Foxboro™DCS(distributed control system)system,enabling efficient data communication between field devices and the DCS system.

Main functions and features

Multi-port configuration:The FBM230 has four ports,each of which can be individually configured in software as RS232,RS422,or RS-485 communication interface standards.This flexibility enables a single FBM230 module to connect multiple similar but not identical devices.

Extensive device connection capabilities:Each FBM230 module can connect up to 64 RS-485 devices or 4 directly connected RS-232 or RS-422 devices.In addition,up to 2000 distributed control interfaces(DCIs)can be connected to read or write data from the Foxboro DCS control station connected to the FBM230.

Data Integration and Conversion:The FBM230 is able to integrate field device data into the Foxboro DCS control database and supports a variety of data types,including analog input or output values(integer or IEEE single-precision floating point),single digital input or output values,and multiple(packed)digital input or output values.

Powerful Software Support:The FBM230 is a universal hardware module that can load different software drivers to identify the specific protocols used by field devices.These drivers can be downloaded from the available protocol library and dynamically loaded into the FBM230 through software code.

Industrial-grade environmental adaptability:The FBM230 is suitable for G3-level(harsh)environments and has high reliability and stability.

Technical Specifications

Input voltage range:redundant 24V DC+5%,-10%

Power consumption:7W(maximum)

Heat dissipation:7W(maximum)

Transmission rate:300,600,1200,2400,4800,9600,19200,38400,57600 and 115200 baud

Protocol:8-bit characters;odd,even or no parity,1 or 2 stop bits

Physical wiring:in accordance with RS-232,RS422 or RS-485 standards of the Electronic Industries Association(EIA)

Application areas

FBM230 modules are widely used in industrial automation systems,including production process control,data acquisition and monitoring.In continuous process manufacturing industries such as chemical,petroleum,and natural gas production processes,FBM230 modules can be used to monitor and control various production process parameters to ensure the stability and efficiency of the production process.

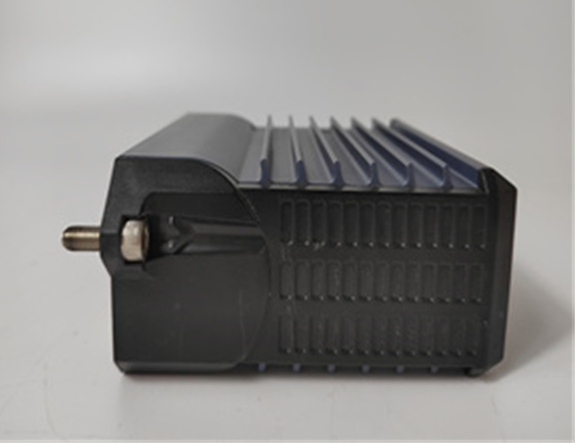

Foxboro FBM230 P0926GU

The Foxboro FBM230 P0926GU is a Field Device System Integrator (FDSI) module designed for seamless communication between field devices and the Foxboro I/A Series DCS system. It provides reliable serial communication capabilities fo

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...