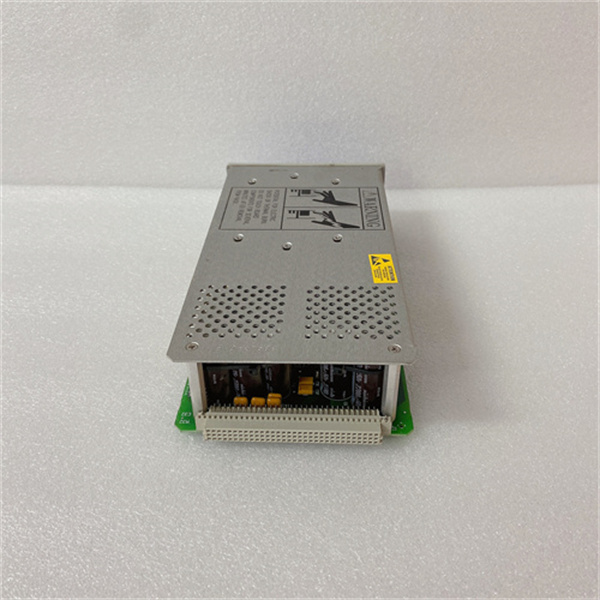

BENTLY 133819-02 Product Details

BENTLY 133819-02 is a non-isolated I/O module in the field of industrial automation,which is mainly used for temperature and vibration monitoring systems and belongs to the core component of the Bentley Nevada 3500 series framework.The following is a detailed introduction of its core functions and technical characteristics.

Core functions

It supports RTD(resistance temperature detector)and thermocouple(TC)input,provides six independent temperature monitoring channels,and can programmably set alarm thresholds,which is suitable for high temperature,low temperature and dangerous environments.

Built-in temperature compensation and signal adjustment functions to ensure measurement accuracy(in line with API 670 standard).

Vibration and displacement monitoring

As a non-isolated I/O module,it can be expanded to connect vortex sensors,accelerometers,etc.to monitor the vibration,displacement and axial offset of rotating machinery(such as turbines and compressors).

It supports dynamic(vibration)and static(position)signal measurement and is suitable for online monitoring of oil film bearing machinery.

Alarm and protection

Through the software configuration of alarm logic,the relay output or communication signal is triggered to realize the real-time protection of equipment overload,abnormal vibration and other states.

Technical parameters

Hardware characteristics

Channel configuration:6 temperature input channels,compatible with RTD(such as PT100)and a variety of thermocouple types(such as K and J).

Isolation:Non-isolation design,suitable for non-hazardous areas or low-interference environments.

Communication interface:Support Ethernet,RS232/485 and other industrial protocols,facilitate integration with PLC and DCS systems.

Environmental adaptability

Working temperature:-20℃to 85℃,adapt to high temperature,high humidity and strong vibration scenes.

Protection level:IP65(partial configuration),support industrial-grade anti-interference design.

Software compatibility

Through the configuration parameters of the 3500 framework configuration software,it supports online modification of alarm thresholds,signal types and communication protocols.

Typical application scenarios

Energy and power industry

Monitor the vibration and temperature of turbines and generators in power plants to prevent downtime caused by bearing wear or axial offset.

Petrochemical industry

It is used for real-time monitoring of the temperature and vibration of centrifugal compressors and pump groups to ensure production continuity.

Machinery manufacturing

It is integrated into the production line equipment to realize the dynamic performance analysis and fault warning of rotating components.

Technical advantages

High integration:The single module supports multi-type sensor input,reducing hardware redundancy.

Flexible configuration:adapt to complex industrial needs through software-defined monitoring parameters and alarm logic.

Industrial-grade reliability:anti-electromagnetic interference design to ensure long-term stable operation.

Bently Nevada 3500/61-01-00 133819-02

The Bently Nevada 3500/61-01-00 133819-02 RTD/TC Non-Isolated I/O Module is an advanced industrial module designed for accurate measurement and monitoring of temperature in industrial machinery and systems. Specifically tailored for use in

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...