VIBRO 573-935-202C Product Introduction

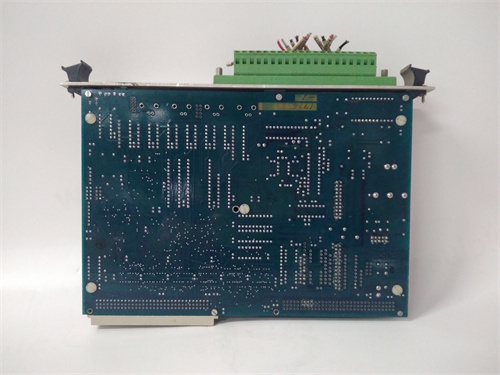

VIBRO 573-935-202C is a motion control module.Here is a detailed introduction to it.

Basic information

Manufacturer:VIBRO(or DRESSER-RAND,which may vary depending on sales channels and suppliers)

Model:573-935-202C

Functional features

Motion control:This module is mainly used for applications that control motion and position,and can achieve precise motion control,such as position control,speed control,force/torque control,etc.

Monitoring and feedback:It has the function of monitoring position and speed,and can provide real-time feedback on the motion state to ensure the accuracy and stability of the motion.

Actuator control:It can control motion actuators,such as motors or cylinders,to achieve precise motion of automated equipment.

High-precision tasks:It can perform high-precision motion control tasks to meet the needs of the industrial field for high-precision position control and motion control.

Application fields

VIBRO 573-935-202C motion control modules are widely used in various industrial fields,including but not limited to

Automation machinery:It is used for precise control of automated production lines to improve production efficiency.

CNC machine tools:realize precise motion control of machine tools to ensure processing accuracy and efficiency.

Robots:provide precise motion instructions for robots to achieve complex operation tasks.

Printing and packaging equipment:control precise motion in printing and packaging processes to ensure product quality.

Medical equipment:realize precise motion control in medical equipment,such as surgical robots,medical testing equipment,etc.

Laboratory equipment:used for precise motion control in laboratories,such as automated operation of experimental instruments.

Programming and settings

Programming:VIBRO 573-935-202C motion control modules usually need to be programmed and set up to meet specific motion control requirements.Engineers can use specific software tools to create motion control programs to configure the module to perform the required motion tasks.

Settings:The settings of the module may include parameter configuration,motion trajectory planning,actuator selection,etc.The specific setting method may vary depending on the module model and application scenario.

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...