Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

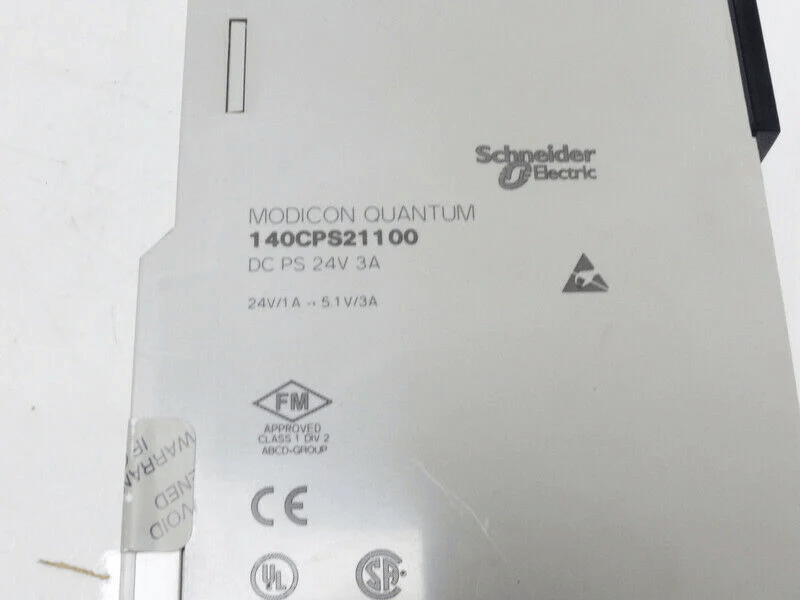

Schneider TSXCFY21 Motion Control Module

Manufacturer:Schneider

Product Number:TSXCFY21

Product Type:Motion Control Module

Origin:France

Dimensions:55 x 180 x 260 mm

Weight:0.38 kg

Views:64

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider TSXCFY21 is a powerful motion control communication module designed for use in Modicon Premium PLC systems. It serves as a key interface between the controller and servo drives or motion devices, ensuring precise and synchronized control over complex automation processes. The module is engineered to handle high-speed communication with Sercos (Serial Real-time Communication System), offering a reliable and deterministic platform for motion-centric applications.

TSXCFY21 supports multiple motion axes and offers configuration flexibility that caters to dynamic industrial environments such as packaging, printing, metal processing, and robotics. As part of Schneider Electric’s robust automation ecosystem, this module guarantees seamless integration, long-term reliability, and high performance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | TSXCFY21 Motion Control Module |

| Manufacturer | Schneider Electric |

| Product Type | Motion Communication Module |

| Supported Protocol | SERCOS Interface (SERCOS I) |

| Number of Motion Axes Supported | Up to 8 axes |

| Bus Interface | Premium backplane bus |

| Compatible PLC Series | Modicon Premium |

| Transmission Speed | 2, 4, or 8 Mbps (configurable) |

| Diagnostic LEDs | Yes |

| Configuration Software | Unity Pro / Concept / PL7 |

| Operating Temperature Range | 0 to 60°C (32 to 140°F) |

| Storage Temperature Range | -40 to 85°C (-40 to 185°F) |

| Relative Humidity | 5% to 95% non-condensing |

| Cooling Method | Natural convection |

| Mounting Type | Rack-mount |

| Protection Category | IP20 |

| Power Supply Voltage | Supplied through PLC backplane |

| Dimensions (W x H x D) | 55 x 180 x 260 mm |

| Weight | 0.38 kg |

| Compliance Standards | CE, UL, CSA, EN61131-2 |

Product Applications

The TSXCFY21 module is suitable for a broad range of industrial applications where motion synchronization and speed control are critical. Common use cases include:

Packaging machinery – coordinating multiple motion axes for wrapping, sealing, and cutting.

Material handling – controlling conveyors, pick-and-place robots, and sorters.

Printing presses – managing high-speed synchronized printing mechanisms.

Textile manufacturing – enabling precision motion control for looms and winders.

Automotive industry – integrating motion control into robotic assembly systems.

CNC and machine tools – executing precise movement control and real-time feedback.

Product Advantages

High-Speed Real-Time Communication: Utilizes the SERCOS interface, delivering deterministic, high-speed control.

Integrated Diagnostics: Built-in LED indicators and software support simplify troubleshooting.

Multi-Axis Coordination: Controls up to 8 motion axes, allowing for highly complex motion profiles.

Seamless PLC Integration: Designed for Modicon Premium systems, offering plug-and-play compatibility.

Flexible Configuration: Supports a variety of setup tools including Unity Pro and PL7.

Compact Design: Saves panel space while maintaining performance.

Robust and Reliable: Operates under industrial conditions, with wide temperature tolerance and high electromagnetic compatibility.

Frequently Asked Questions (FAQ)

What is the primary function of the TSXCFY21 module?

It serves as a SERCOS-based motion control communication interface for Modicon Premium PLCs.

How many motion axes can it control simultaneously?

The TSXCFY21 can control up to 8 independent motion axes.

Which PLC systems are compatible with TSXCFY21?

It is compatible with Schneider’s Modicon Premium series.

Can TSXCFY21 be used with Unity Pro software?

Yes, it is fully supported by Unity Pro, Concept, and PL7 configuration tools.

What communication protocol does it use?

It uses the SERCOS (Serial Real-time Communication System) protocol.

Is this module suitable for high-speed applications?

Absolutely. It supports transmission speeds up to 8 Mbps and offers real-time performance.

What is the module’s protection class?

It has an IP20 protection rating, suitable for installation within enclosures.

What are the dimensions and weight of the TSXCFY21?

Dimensions are 55 x 180 x 260 mm, and it weighs 0.38 kg.

Does the module require external power supply?

No, it draws power directly from the PLC backplane.

What types of industries benefit most from this module?

Industries such as packaging, automotive, textile, printing, and machine tooling commonly use this module.

Schneider TSXCFY21 Motion Control Module

Manufacturer:Schneider

Product Number:TSXCFY21

Product Type:Motion Control Module

Origin:France

Dimensions:55 x 180 x 260 mm

Weight:0.38 kg

Views:64

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider TSXCFY21 is a powerful motion control communication module designed for use in Modicon Premium PLC systems. It serves as a key interface between the controller and servo drives or motion devices, ensuring precise and synchronized control over complex automation processes. The module is engineered to handle high-speed communication with Sercos (Serial Real-time Communication System), offering a reliable and deterministic platform for motion-centric applications.

TSXCFY21 supports multiple motion axes and offers configuration flexibility that caters to dynamic industrial environments such as packaging, printing, metal processing, and robotics. As part of Schneider Electric’s robust automation ecosystem, this module guarantees seamless integration, long-term reliability, and high performance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | TSXCFY21 Motion Control Module |

| Manufacturer | Schneider Electric |

| Product Type | Motion Communication Module |

| Supported Protocol | SERCOS Interface (SERCOS I) |

| Number of Motion Axes Supported | Up to 8 axes |

| Bus Interface | Premium backplane bus |

| Compatible PLC Series | Modicon Premium |

| Transmission Speed | 2, 4, or 8 Mbps (configurable) |

| Diagnostic LEDs | Yes |

| Configuration Software | Unity Pro / Concept / PL7 |

| Operating Temperature Range | 0 to 60°C (32 to 140°F) |

| Storage Temperature Range | -40 to 85°C (-40 to 185°F) |

| Relative Humidity | 5% to 95% non-condensing |

| Cooling Method | Natural convection |

| Mounting Type | Rack-mount |

| Protection Category | IP20 |

| Power Supply Voltage | Supplied through PLC backplane |

| Dimensions (W x H x D) | 55 x 180 x 260 mm |

| Weight | 0.38 kg |

| Compliance Standards | CE, UL, CSA, EN61131-2 |

Product Applications

The TSXCFY21 module is suitable for a broad range of industrial applications where motion synchronization and speed control are critical. Common use cases include:

Packaging machinery – coordinating multiple motion axes for wrapping, sealing, and cutting.

Material handling – controlling conveyors, pick-and-place robots, and sorters.

Printing presses – managing high-speed synchronized printing mechanisms.

Textile manufacturing – enabling precision motion control for looms and winders.

Automotive industry – integrating motion control into robotic assembly systems.

CNC and machine tools – executing precise movement control and real-time feedback.

Product Advantages

High-Speed Real-Time Communication: Utilizes the SERCOS interface, delivering deterministic, high-speed control.

Integrated Diagnostics: Built-in LED indicators and software support simplify troubleshooting.

Multi-Axis Coordination: Controls up to 8 motion axes, allowing for highly complex motion profiles.

Seamless PLC Integration: Designed for Modicon Premium systems, offering plug-and-play compatibility.

Flexible Configuration: Supports a variety of setup tools including Unity Pro and PL7.

Compact Design: Saves panel space while maintaining performance.

Robust and Reliable: Operates under industrial conditions, with wide temperature tolerance and high electromagnetic compatibility.

Frequently Asked Questions (FAQ)

What is the primary function of the TSXCFY21 module?

It serves as a SERCOS-based motion control communication interface for Modicon Premium PLCs.

How many motion axes can it control simultaneously?

The TSXCFY21 can control up to 8 independent motion axes.

Which PLC systems are compatible with TSXCFY21?

It is compatible with Schneider’s Modicon Premium series.

Can TSXCFY21 be used with Unity Pro software?

Yes, it is fully supported by Unity Pro, Concept, and PL7 configuration tools.

What communication protocol does it use?

It uses the SERCOS (Serial Real-time Communication System) protocol.

Is this module suitable for high-speed applications?

Absolutely. It supports transmission speeds up to 8 Mbps and offers real-time performance.

What is the module’s protection class?

It has an IP20 protection rating, suitable for installation within enclosures.

What are the dimensions and weight of the TSXCFY21?

Dimensions are 55 x 180 x 260 mm, and it weighs 0.38 kg.

Does the module require external power supply?

No, it draws power directly from the PLC backplane.

What types of industries benefit most from this module?

Industries such as packaging, automotive, textile, printing, and machine tooling commonly use this module.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...