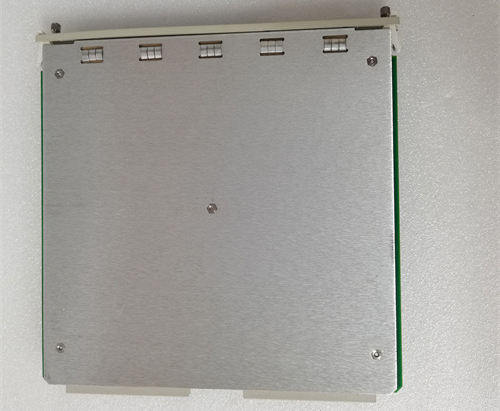

BENTLY 3500/33 149986-01 Product Introduction

BENTLY 3500/33 149986-01 is a high-performance monitoring device,commonly used in industrial automation control systems,especially in situations where mechanical equipment needs to be accurately monitored and protected.It can monitor multiple parameters such as vibration,temperature,pressure,and trigger corresponding protection measures to ensure the safe operation of the equipment.

Main Features

High-precision measurement

The device can accurately measure the rotation speed or vibration level of mechanical equipment,providing real-time and accurate data support for the control system.

Real-time monitoring

It has real-time monitoring function,which can capture changes in the operating status of the equipment,help prevent equipment failures and reduce production risks.

Good compatibility

Compatible with a variety of control systems and sensors,it can be easily integrated into existing industrial automation systems.

Mechanical equipment protection:By monitoring the equipment status,protective measures can be triggered,such as cutting off the power supply or taking other emergency shutdown measures to prevent equipment damage or accidents.

Data acquisition and analysis:The device can be used to collect monitored data for real-time analysis,fault diagnosis and maintenance planning.

Remote monitoring and control:Some systems may support remote monitoring and control functions,enabling operators to monitor equipment status through remote access and take necessary actions.

Application areas

BENTLY 3500/33 149986-01 is widely used in the following fields

Power plant

Used to monitor the vibration and temperature parameters of key equipment such as generators and transformers to ensure the stability and safety of power supply.

Oil and gas production

During the extraction,processing and transportation of oil and gas,it is used to monitor the operating status of equipment such as pumps and compressors to prevent equipment failures and leakage accidents.

Chemical plant

During the chemical production process,it is used to monitor the vibration and temperature parameters of equipment such as reactors and compressors to ensure the stability and safety of the production process.

Manufacturing:In the manufacturing industry,it is used to monitor various mechanical equipment on the production line to ensure the continuity and stability of the production process.

Triconex 3500/33 149986-01

The BENTLY 3500/33 149986-01 module, also known as the 149986-01 model in Bently Nevada’s 3500/33 series, is a 16 channel relay output module widely used in the field of industrial automation control. The following is a detailed analysis

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...