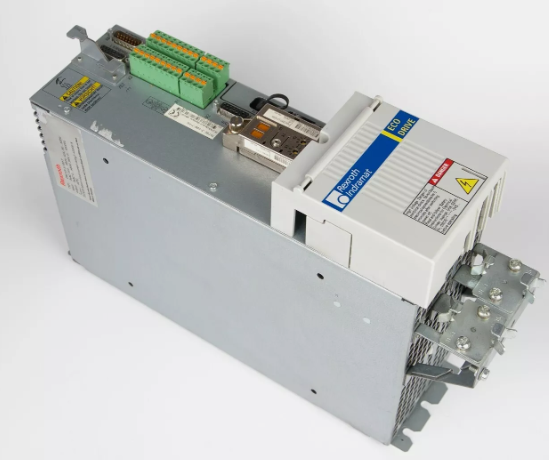

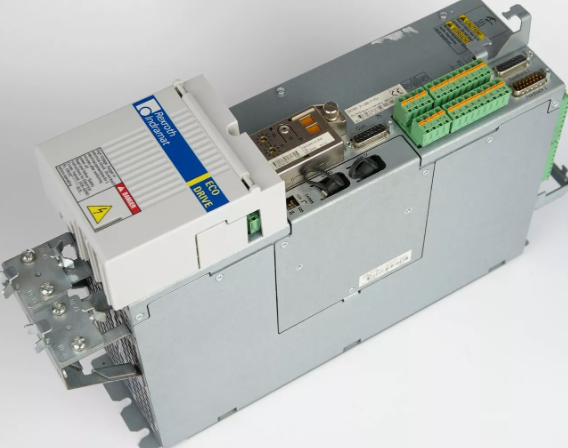

REXROTH DKC02.3-100-7-FW Detailed Introduction

REXROTH DKC02.3-100-7-FW is a servo drive controller module produced by Rexroth,Germany,and belongs to the Rexroth ACOPOSmicro series.The following is a detailed analysis of the product.

Product Overview

Model and Use

DKC02.3-100-7-FW is a high-performance servo drive in the Rexroth ACOPOSmicro series,used to drive servo motors to achieve high-precision and high-dynamic motion control.

Application Areas

Widely used in automation equipment such as machine tools,packaging machinery,printing machinery,textile machinery,robots,etc.

Technical Features

High Power Density

The module is compactly designed,with each axis occupying less than 50cm²,suitable for multi-axis applications,saving space in the power distribution cabinet.

Supports rated voltages from 24V to 64VDC,motor current can reach 10A(peak),servo motor continuous current is 8A,and peak current is higher.

Flexible encoder support

Supports a variety of optional encoder systems,suitable for different types of stepper motors and servo motors.

Powerful protection functions

Built-in protection functions such as overcurrent,overheating,overvoltage,and undervoltage ensure safe operation of the equipment.

Output appropriate warning and error messages through the fieldbus to facilitate fault diagnosis.

High-speed processing capability

Adopts digital signal processor(DSP)as the control core to implement complex control algorithms and support digital,networked and intelligent control.

Additional functions can be added through optional modules without taking up additional space to meet personalized needs.

Three,product advantages

High-precision control:Achieve high-precision position,speed and torque control to meet precision machining needs.

High reliability:The drive circuit designed with intelligent power module(IPM)integrates multiple protection functions to extend the service life of the equipment.

Easy to integrate:Supports multiple fieldbus protocols(such as RS232,RS485,optical fiber,InterBus,ProfiBus,etc.),which is easy to integrate with other automation equipment.

Strong flexibility:Suitable for different types of motors and encoders to meet diverse application needs.

Application scenarios

CNC machine tools:achieve high-precision processing control and improve product quality.

Packaging machinery:optimize packaging processes and improve production efficiency.

Printing machinery:ensure printing accuracy and reduce scrap rate.

Textile machinery:achieve high-speed and high-precision textile control.

Robots:drive robot joints to achieve flexible motion control.

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...