Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

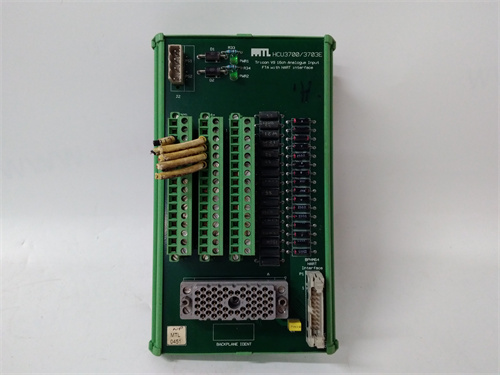

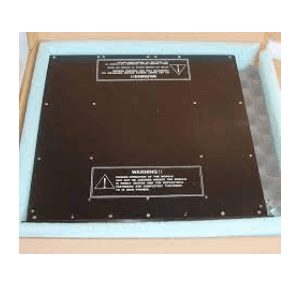

Triconex 4118 Enhanced Communication Module

Manufacturer:Triconex

Product Number:4118

Product Type:Enhanced Communication Module

Origin:USA

Dimensions:326 x 260 x 50 mm

Weight:1.8 kg

Views:101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 4118 Enhanced Communication Module is a core component within the Triconex line of safety and critical control systems, produced by Schneider Electric. Designed to provide robust and reliable communication between Tricon controllers and external devices, the 4118 module is integral in mission-critical environments where high availability and integrity are paramount.

This enhanced communication module facilitates high-speed serial communication using Modbus, supporting both master and slave configurations. With comprehensive diagnostic capabilities, fault tolerance, and deterministic data exchange, the Triconex 4118 module plays a vital role in industries like oil and gas, chemical processing, power generation, and other sectors requiring high-integrity safety systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Triconex 4118 Enhanced Communication Module |

| Manufacturer | Schneider Electric (Triconex) |

| Product Type | Serial Communication Module |

| Communication Protocols | Modbus RTU (Master/Slave), RS-232/RS-485 |

| Baud Rate | Up to 115.2 kbps |

| No. of Serial Ports | 2 (Configurable as RS-232 or RS-485) |

| Power Consumption | 5.0 W (typical) |

| Redundancy Support | Yes (Hot-standby capable) |

| Isolation | Optical isolation between system and communication |

| Diagnostic Features | Self-checking, system status LEDs, fault reporting |

| System Compatibility | Tricon v10 and later |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

| Vibration | 1 g, 10–150 Hz |

| Dimensions (H x W x D) | 326 x 260 x 50 mm |

| Weight | 1.8 kg |

| Mounting | 19″ rack-based; Slot-in Tricon chassis |

| Certification | TÜV, SIL 3 (IEC 61508), CE, CSA, FM Class 1 Div 2 |

Applications

The Triconex 4118 Enhanced Communication Module is widely used across various industries and applications, including:

Oil & Gas (Upstream, Midstream, Downstream): Communication between safety controllers and SCADA/DCS.

Power Generation: Integration of turbine control with safety interlock systems.

Chemical & Petrochemical Plants: High-integrity process interlocks with secure field device communication.

Pharmaceutical Manufacturing: GMP-compliant safety systems requiring robust traceability and diagnostics.

Water & Wastewater Treatment: Safety interlocks and process monitoring.

Pulp & Paper Industry: Coordination of process safety with legacy systems through Modbus links.

Advantages

High Reliability: Built on Triconex’s triple-modular-redundant (TMR) architecture, ensuring zero single-point failures.

Flexible Communication: Dual-port support with RS-232 and RS-485 configurations for versatile integration.

Modbus Protocol Support: Seamless integration with DCS, SCADA, HMIs, and legacy systems using industry-standard protocols.

Self-Diagnostics: Built-in monitoring and status reporting enhance maintainability and reduce downtime.

Redundancy Capable: Can be configured in redundant pairs to ensure continuous operation during failure events.

Robust Design: Industrial-grade construction with resistance to harsh environmental conditions.

Hot-Swappable: Supports online replacement without system shutdown.

TÜV Certified for SIL 3: Meets stringent functional safety standards.

Seamless Integration: Fully compatible with Tricon v10 systems and higher.

Field-Proven: Thousands of installations worldwide in mission-critical facilities.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Triconex 4118 module?

It enables serial communication between Tricon safety controllers and external devices using Modbus protocol.

-

Which communication standards are supported?

RS-232 and RS-485 with Modbus RTU protocol are supported.

-

Can I use the 4118 module in redundant configurations?

Yes, it supports hot-standby redundancy for critical applications.

-

Is the 4118 module compatible with all Tricon controllers?

It is compatible with Tricon v10 systems and later.

-

Does the module support hot-swapping?

Yes, the 4118 module can be replaced while the system is online.

-

What certifications does the module have?

TÜV SIL 3 (IEC 61508), CE, CSA, FM approvals.

-

Can the module be used in hazardous locations?

Yes, it is certified for use in Class 1, Division 2 environments.

-

Does the module provide any built-in diagnostics?

Yes, it includes self-checking mechanisms and LED status indicators.

-

How many communication ports are available?

It provides two serial communication ports.

-

What are the environmental limits for the module?

Operating temperature is 0°C to 60°C, and humidity range is 5–95% non-condensing.

Triconex 4118 Enhanced Communication Module

Manufacturer:Triconex

Product Number:4118

Product Type:Enhanced Communication Module

Origin:USA

Dimensions:326 x 260 x 50 mm

Weight:1.8 kg

Views:101

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 4118 Enhanced Communication Module is a core component within the Triconex line of safety and critical control systems, produced by Schneider Electric. Designed to provide robust and reliable communication between Tricon controllers and external devices, the 4118 module is integral in mission-critical environments where high availability and integrity are paramount.

This enhanced communication module facilitates high-speed serial communication using Modbus, supporting both master and slave configurations. With comprehensive diagnostic capabilities, fault tolerance, and deterministic data exchange, the Triconex 4118 module plays a vital role in industries like oil and gas, chemical processing, power generation, and other sectors requiring high-integrity safety systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Triconex 4118 Enhanced Communication Module |

| Manufacturer | Schneider Electric (Triconex) |

| Product Type | Serial Communication Module |

| Communication Protocols | Modbus RTU (Master/Slave), RS-232/RS-485 |

| Baud Rate | Up to 115.2 kbps |

| No. of Serial Ports | 2 (Configurable as RS-232 or RS-485) |

| Power Consumption | 5.0 W (typical) |

| Redundancy Support | Yes (Hot-standby capable) |

| Isolation | Optical isolation between system and communication |

| Diagnostic Features | Self-checking, system status LEDs, fault reporting |

| System Compatibility | Tricon v10 and later |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% RH, non-condensing |

| Vibration | 1 g, 10–150 Hz |

| Dimensions (H x W x D) | 326 x 260 x 50 mm |

| Weight | 1.8 kg |

| Mounting | 19″ rack-based; Slot-in Tricon chassis |

| Certification | TÜV, SIL 3 (IEC 61508), CE, CSA, FM Class 1 Div 2 |

Applications

The Triconex 4118 Enhanced Communication Module is widely used across various industries and applications, including:

Oil & Gas (Upstream, Midstream, Downstream): Communication between safety controllers and SCADA/DCS.

Power Generation: Integration of turbine control with safety interlock systems.

Chemical & Petrochemical Plants: High-integrity process interlocks with secure field device communication.

Pharmaceutical Manufacturing: GMP-compliant safety systems requiring robust traceability and diagnostics.

Water & Wastewater Treatment: Safety interlocks and process monitoring.

Pulp & Paper Industry: Coordination of process safety with legacy systems through Modbus links.

Advantages

High Reliability: Built on Triconex’s triple-modular-redundant (TMR) architecture, ensuring zero single-point failures.

Flexible Communication: Dual-port support with RS-232 and RS-485 configurations for versatile integration.

Modbus Protocol Support: Seamless integration with DCS, SCADA, HMIs, and legacy systems using industry-standard protocols.

Self-Diagnostics: Built-in monitoring and status reporting enhance maintainability and reduce downtime.

Redundancy Capable: Can be configured in redundant pairs to ensure continuous operation during failure events.

Robust Design: Industrial-grade construction with resistance to harsh environmental conditions.

Hot-Swappable: Supports online replacement without system shutdown.

TÜV Certified for SIL 3: Meets stringent functional safety standards.

Seamless Integration: Fully compatible with Tricon v10 systems and higher.

Field-Proven: Thousands of installations worldwide in mission-critical facilities.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Triconex 4118 module?

It enables serial communication between Tricon safety controllers and external devices using Modbus protocol.

-

Which communication standards are supported?

RS-232 and RS-485 with Modbus RTU protocol are supported.

-

Can I use the 4118 module in redundant configurations?

Yes, it supports hot-standby redundancy for critical applications.

-

Is the 4118 module compatible with all Tricon controllers?

It is compatible with Tricon v10 systems and later.

-

Does the module support hot-swapping?

Yes, the 4118 module can be replaced while the system is online.

-

What certifications does the module have?

TÜV SIL 3 (IEC 61508), CE, CSA, FM approvals.

-

Can the module be used in hazardous locations?

Yes, it is certified for use in Class 1, Division 2 environments.

-

Does the module provide any built-in diagnostics?

Yes, it includes self-checking mechanisms and LED status indicators.

-

How many communication ports are available?

It provides two serial communication ports.

-

What are the environmental limits for the module?

Operating temperature is 0°C to 60°C, and humidity range is 5–95% non-condensing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...