Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

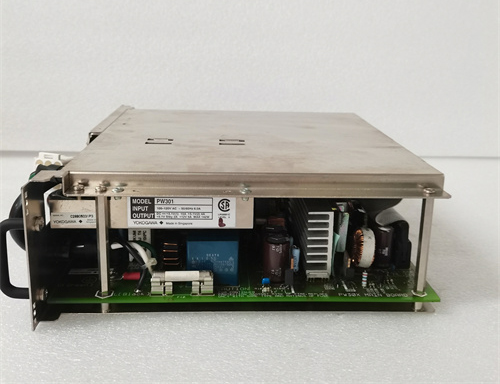

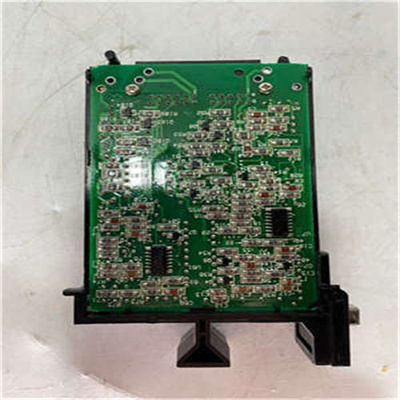

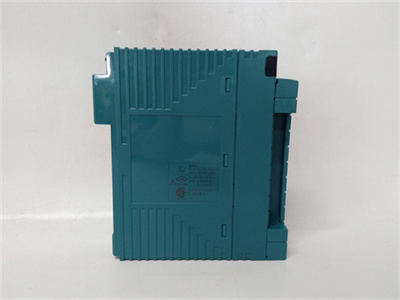

Yokogawa AAI841-H50/K4A00 Analog I/O Module

Manufacturer:Yokogawa

Product Number:AAI841-H50/K4A00

Product Type:Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight:0.3 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AAI841-H50/K4A00 Analog I/O Module is engineered for precise analog signal processing in industrial automation systems, especially within Yokogawa’s distributed control systems (DCS). This module is designed to handle both analog input and output signals, converting electrical signals from field devices into digital data for the control system, and vice versa. Its robust design ensures reliable operation in demanding industrial environments where signal accuracy and integrity are essential.

This model features enhanced performance compared to earlier versions, supporting higher signal fidelity and improved noise immunity. It is tailored for processes that demand high accuracy and fast response, such as chemical processing, power generation, and oil refining. The AAI841-H50/K4A00 integrates tightly with Yokogawa’s CENTUM VP system, allowing for streamlined system configuration and operation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AAI841-H50/K4A00 |

| Module Type | Analog Input/Output Module |

| Number of Channels | 4 (Analog Input/Output) |

| Input Signal Range | ±10 V, 0-20 mA, 4-20 mA selectable |

| Output Signal Range | 0-20 mA or 4-20 mA |

| Resolution | 16-bit A/D and D/A conversion |

| Accuracy | ±0.05% of full scale (improved precision) |

| Response Time | Typically less than 50 ms |

| Power Supply | 24 V DC nominal |

| Communication Interface | Compatible with Yokogawa DCS bus |

| Operating Temperature | -10°C to +65°C |

| Storage Temperature | -25°C to +75°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Isolation | Channel-to-channel and channel-to-ground isolation |

| Dimensions (WxHxD) | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Mounting | DIN rail or rack mount |

Applications

The AAI841-H50/K4A00 is utilized in many industrial settings where precision analog signal conversion is crucial. Common applications include:

-

Chemical plants, for managing complex process variables such as flow, temperature, and pressure

-

Power generation plants, for controlling and monitoring turbine and boiler systems

-

Oil and gas refineries, supporting critical process instrumentation

-

Water and wastewater treatment facilities, enabling control of pumps and chemical dosing

-

Food and beverage manufacturing, ensuring accurate process monitoring and quality control

-

Pharmaceutical production environments requiring strict process parameter control

Its ability to interface with various sensor types such as thermocouples, RTDs, and current transmitters makes it versatile across industries.

Advantages

High Accuracy and Stability: The module delivers enhanced precision with ±0.05% accuracy and stable long-term performance.

Fast Signal Response: Response time under 50 ms supports fast process dynamics and control loops.

Robust Construction: Designed to resist industrial noise and operate reliably over a wide temperature and humidity range.

Wide Signal Compatibility: Accepts multiple analog input types and provides configurable outputs suitable for a broad range of devices.

Electrical Isolation: Protects system integrity with thorough channel isolation to reduce signal interference.

Compact and Easy to Install: Small form factor compatible with DIN rail or rack mounting simplifies integration.

Seamless DCS Integration: Optimized for Yokogawa’s CENTUM and other DCS platforms, enhancing operational efficiency and ease of maintenance.

Frequently Asked Questions (FAQ)

What analog input signals can the AAI841-H50/K4A00 accept?

It supports ±10 V voltage input, 0-20 mA, and 4-20 mA current input signals, configurable per application.

Are output signal ranges configurable on this module?

Yes, output signals can be configured for 0-20 mA or 4-20 mA ranges.

What is the resolution and accuracy of this module?

It uses 16-bit A/D and D/A converters with a precision accuracy of ±0.05% of full scale.

Does the module provide electrical isolation between channels?

Yes, each channel is isolated from others and from the ground, minimizing interference.

What is the signal processing response time?

The module processes signals with a response time typically less than 50 milliseconds.

What power supply voltage is required?

It requires a 24 V DC nominal power supply for operation.

Can this module operate under high humidity conditions?

Yes, it operates reliably in relative humidity up to 95% without condensation.

Is this module compatible with Yokogawa’s DCS communication standards?

Yes, it integrates seamlessly with Yokogawa DCS communication protocols.

Can it handle both analog input and output signals simultaneously?

Yes, the module supports mixed analog input and output across its 4 channels.

What routine maintenance is recommended?

Regular calibration checks, cleaning of terminals, and verifying signal accuracy help maintain optimal performance.

Yokogawa AAI841-H50/K4A00 Analog I/O Module

Manufacturer:Yokogawa

Product Number:AAI841-H50/K4A00

Product Type:Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight:0.3 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AAI841-H50/K4A00 Analog I/O Module is engineered for precise analog signal processing in industrial automation systems, especially within Yokogawa’s distributed control systems (DCS). This module is designed to handle both analog input and output signals, converting electrical signals from field devices into digital data for the control system, and vice versa. Its robust design ensures reliable operation in demanding industrial environments where signal accuracy and integrity are essential.

This model features enhanced performance compared to earlier versions, supporting higher signal fidelity and improved noise immunity. It is tailored for processes that demand high accuracy and fast response, such as chemical processing, power generation, and oil refining. The AAI841-H50/K4A00 integrates tightly with Yokogawa’s CENTUM VP system, allowing for streamlined system configuration and operation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AAI841-H50/K4A00 |

| Module Type | Analog Input/Output Module |

| Number of Channels | 4 (Analog Input/Output) |

| Input Signal Range | ±10 V, 0-20 mA, 4-20 mA selectable |

| Output Signal Range | 0-20 mA or 4-20 mA |

| Resolution | 16-bit A/D and D/A conversion |

| Accuracy | ±0.05% of full scale (improved precision) |

| Response Time | Typically less than 50 ms |

| Power Supply | 24 V DC nominal |

| Communication Interface | Compatible with Yokogawa DCS bus |

| Operating Temperature | -10°C to +65°C |

| Storage Temperature | -25°C to +75°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Isolation | Channel-to-channel and channel-to-ground isolation |

| Dimensions (WxHxD) | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Mounting | DIN rail or rack mount |

Applications

The AAI841-H50/K4A00 is utilized in many industrial settings where precision analog signal conversion is crucial. Common applications include:

-

Chemical plants, for managing complex process variables such as flow, temperature, and pressure

-

Power generation plants, for controlling and monitoring turbine and boiler systems

-

Oil and gas refineries, supporting critical process instrumentation

-

Water and wastewater treatment facilities, enabling control of pumps and chemical dosing

-

Food and beverage manufacturing, ensuring accurate process monitoring and quality control

-

Pharmaceutical production environments requiring strict process parameter control

Its ability to interface with various sensor types such as thermocouples, RTDs, and current transmitters makes it versatile across industries.

Advantages

High Accuracy and Stability: The module delivers enhanced precision with ±0.05% accuracy and stable long-term performance.

Fast Signal Response: Response time under 50 ms supports fast process dynamics and control loops.

Robust Construction: Designed to resist industrial noise and operate reliably over a wide temperature and humidity range.

Wide Signal Compatibility: Accepts multiple analog input types and provides configurable outputs suitable for a broad range of devices.

Electrical Isolation: Protects system integrity with thorough channel isolation to reduce signal interference.

Compact and Easy to Install: Small form factor compatible with DIN rail or rack mounting simplifies integration.

Seamless DCS Integration: Optimized for Yokogawa’s CENTUM and other DCS platforms, enhancing operational efficiency and ease of maintenance.

Frequently Asked Questions (FAQ)

What analog input signals can the AAI841-H50/K4A00 accept?

It supports ±10 V voltage input, 0-20 mA, and 4-20 mA current input signals, configurable per application.

Are output signal ranges configurable on this module?

Yes, output signals can be configured for 0-20 mA or 4-20 mA ranges.

What is the resolution and accuracy of this module?

It uses 16-bit A/D and D/A converters with a precision accuracy of ±0.05% of full scale.

Does the module provide electrical isolation between channels?

Yes, each channel is isolated from others and from the ground, minimizing interference.

What is the signal processing response time?

The module processes signals with a response time typically less than 50 milliseconds.

What power supply voltage is required?

It requires a 24 V DC nominal power supply for operation.

Can this module operate under high humidity conditions?

Yes, it operates reliably in relative humidity up to 95% without condensation.

Is this module compatible with Yokogawa’s DCS communication standards?

Yes, it integrates seamlessly with Yokogawa DCS communication protocols.

Can it handle both analog input and output signals simultaneously?

Yes, the module supports mixed analog input and output across its 4 channels.

What routine maintenance is recommended?

Regular calibration checks, cleaning of terminals, and verifying signal accuracy help maintain optimal performance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...