Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

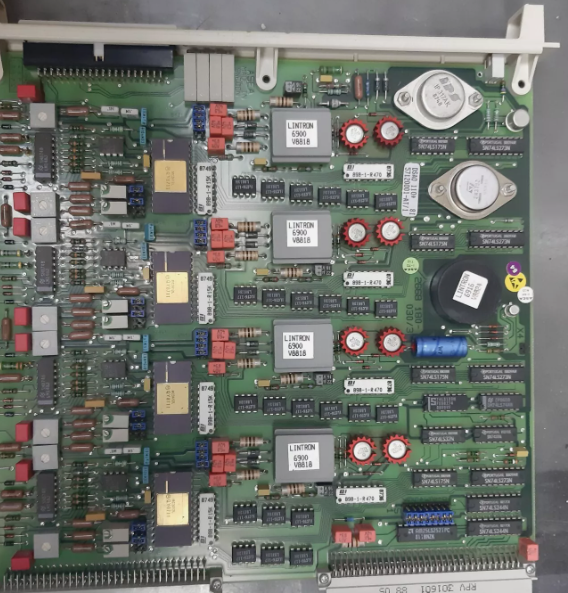

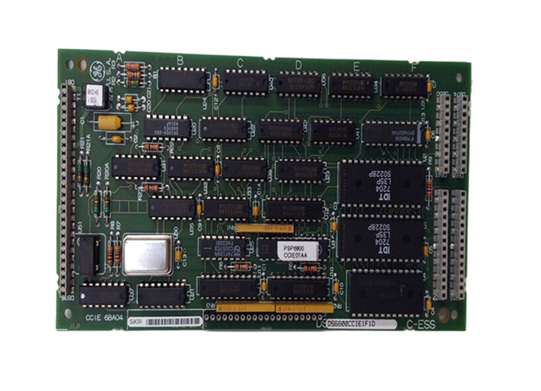

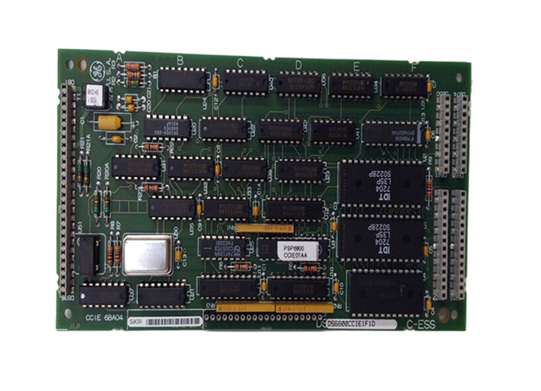

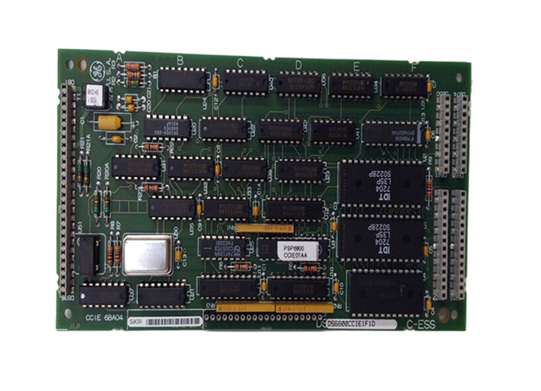

General Electric DS6800CCIE1F1D DC Servo Drive Unit

Module Number:DS6800CCIE1F1D

Product status:Discontinued

Delivery time:In stock

Sales country:All over the world

Product situation:Brandnew , one year warranty

Product Description

The hydraulic pressure of DS6800CCIE1F1D is much higher than the pneumatic pressure, generally around 70kPa, so hydraulic transmission industrial robots have great gripping ability, up to thousands of Newtons. This type of industrial robot has a compact structure, smooth transmission, and sensitive movements, but requires high sealing requirements and is not suitable for working in high or low temperature environments.

DS6800CCIE1F1D is currently the most commonly used type of industrial robot, not only because there are many types of electric motors available for industrial robot design, but also because they can use various flexible control methods. In the early days, stepper motor drive was commonly used, and later DC servo drive units were developed. Currently, AC servo drive units are also rapidly developing. These driving units either directly drive the operator or decelerate and drive through devices such as harmonic reducers, with a very compact and simple structure.

DS6800CCIE1F1D is developed based on the control technology of traditional mechanical systems, so there is no fundamental difference between the two. However, industrial robot control systems also have many special features. Its characteristics are as follows:

Industrial robots have several joints. A typical industrial robot has five or six joints, each of which is controlled by a servo system. The motion of multiple joints requires the coordination of various servo systems

General Electric DS6800CCIE1F1D DC Servo Drive Unit

Module Number:DS6800CCIE1F1D

Product status:Discontinued

Delivery time:In stock

Sales country:All over the world

Product situation:Brandnew , one year warranty

Product Description

The hydraulic pressure of DS6800CCIE1F1D is much higher than the pneumatic pressure, generally around 70kPa, so hydraulic transmission industrial robots have great gripping ability, up to thousands of Newtons. This type of industrial robot has a compact structure, smooth transmission, and sensitive movements, but requires high sealing requirements and is not suitable for working in high or low temperature environments.

DS6800CCIE1F1D is currently the most commonly used type of industrial robot, not only because there are many types of electric motors available for industrial robot design, but also because they can use various flexible control methods. In the early days, stepper motor drive was commonly used, and later DC servo drive units were developed. Currently, AC servo drive units are also rapidly developing. These driving units either directly drive the operator or decelerate and drive through devices such as harmonic reducers, with a very compact and simple structure.

DS6800CCIE1F1D is developed based on the control technology of traditional mechanical systems, so there is no fundamental difference between the two. However, industrial robot control systems also have many special features. Its characteristics are as follows:

Industrial robots have several joints. A typical industrial robot has five or six joints, each of which is controlled by a servo system. The motion of multiple joints requires the coordination of various servo systems

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...