Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

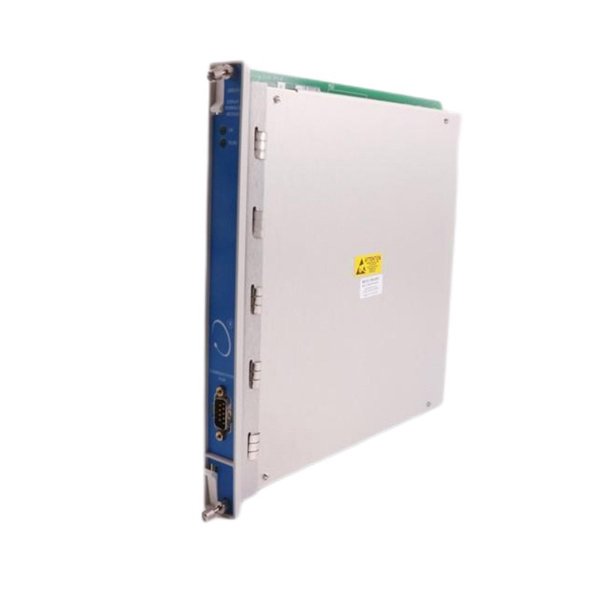

Bently Nevada 3500/93 135799-01 Display Interface Module

Manufacturer:Bently Nevada

Product Number:3500/93 135799-01

Product Type:Display interface module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.82kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/93 135799-01 Display Interface Module is a vital component designed to interface the Bently Nevada 3500 Machinery Protection System with external display units, operator panels, or Human Machine Interfaces (HMIs). This module translates and presents critical machinery condition data, alarms, and status information in a user-friendly format, facilitating real-time monitoring and rapid response.

It provides a reliable communication bridge between the 3500 system’s monitoring modules and display devices, ensuring operators and maintenance personnel have clear visibility into machinery health, enabling proactive decision-making to reduce downtime and prevent catastrophic failures.

Key Features

-

Interfaces the 3500 system with external display units and HMIs

-

Translates machinery protection data into standard display protocols

-

Supports real-time visualization of vibration, temperature, speed, alarms, and diagnostic data

-

Provides configurable display mapping to customize information presentation

-

LED indicators for module health, communication, and power status

-

Seamless integration within the Bently Nevada 3500 system architecture

-

Rugged design for reliable operation in industrial environments

-

Facilitates operator awareness and rapid fault identification

-

Supports multiple display communication standards

-

Field-replaceable module for ease of maintenance

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Bently Nevada 3500/93 Display Interface Module |

| Model Number | 3500/93 |

| Part Number | 135799-01 |

| Function | Interface between 3500 system and external display/HMI |

| Supported Display Protocols | ASCII, Modbus, proprietary Bently Nevada protocols |

| Communication Interface | Serial RS-232 / RS-485 (configurable) |

| Data Types Supported | Vibration, temperature, speed, alarm status, diagnostics |

| Diagnostic Indicators | LEDs for power, communication status, fault indication |

| Power Supply | Supplied via 3500 system rack backplane |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Certifications | CE, CSA, ATEX, IECEx (region dependent) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

Industry Applications

The 3500/93 Display Interface Module is used in industries where clear, real-time machinery data visualization is critical for operational safety and efficiency:

Oil & Gas: Real-time display of compressor and turbine condition for operators

Power Generation: Visualization of generator and turbine machinery health parameters

Petrochemical: Display of critical process equipment condition for preventive maintenance

Marine & Offshore: Operator interface for shaft and auxiliary machinery monitoring

Metals & Mining: Displaying vibration and temperature data for heavy equipment

Industrial Automation: Integration with plant HMIs for machinery protection status

Product Advantages

Enhanced Operator Awareness: Provides clear, real-time visualization of machinery health data

Flexible Display Compatibility: Supports multiple communication protocols and standards

Seamless System Integration: Designed for straightforward integration with 3500 series systems

Rugged and Reliable: Industrial design ensures consistent operation in demanding environments

Customizable Data Presentation: Configurable display mapping allows tailored operator views

Quick Diagnostics: LED indicators facilitate easy troubleshooting and system health checks

Field-Serviceable: Module can be replaced in the field to minimize downtime

Improved Maintenance Response: Enables rapid identification of faults and alarm conditions

Frequently Asked Questions (FAQ)

1. What is the primary purpose of the 3500/93 Display Interface Module?

It serves as the communication link between the 3500 system and external displays or HMIs, translating machine data into a readable format.

2. Which communication interfaces does the module support?

It supports serial RS-232 and RS-485 communication, configurable per system requirements.

3. What data types can be displayed through this module?

The module supports vibration, temperature, speed, alarm status, and diagnostic data.

4. Is the module compatible with standard display protocols?

Yes, it supports ASCII, Modbus, and proprietary Bently Nevada display protocols.

5. How is the module powered?

It receives power from the Bently Nevada 3500 system rack backplane.

6. Can the display data be customized?

Yes, display mapping is configurable to tailor information presentation for specific operator needs.

7. Is the module suitable for harsh industrial environments?

Yes, it is designed for operation between -30°C and +65°C in industrial settings.

8. Does the module include diagnostic indicators?

Yes, LED indicators provide information on power, communication status, and faults.

9. Is the module field-replaceable?

Yes, it is designed for easy field replacement to minimize downtime.

10. In which industries is this module commonly used?

Oil & gas, power generation, petrochemical, marine, mining, and industrial automation sectors.

Bently Nevada 3500/93 135799-01 Display Interface Module

Manufacturer:Bently Nevada

Product Number:3500/93 135799-01

Product Type:Display interface module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.82kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/93 135799-01 Display Interface Module is a vital component designed to interface the Bently Nevada 3500 Machinery Protection System with external display units, operator panels, or Human Machine Interfaces (HMIs). This module translates and presents critical machinery condition data, alarms, and status information in a user-friendly format, facilitating real-time monitoring and rapid response.

It provides a reliable communication bridge between the 3500 system’s monitoring modules and display devices, ensuring operators and maintenance personnel have clear visibility into machinery health, enabling proactive decision-making to reduce downtime and prevent catastrophic failures.

Key Features

-

Interfaces the 3500 system with external display units and HMIs

-

Translates machinery protection data into standard display protocols

-

Supports real-time visualization of vibration, temperature, speed, alarms, and diagnostic data

-

Provides configurable display mapping to customize information presentation

-

LED indicators for module health, communication, and power status

-

Seamless integration within the Bently Nevada 3500 system architecture

-

Rugged design for reliable operation in industrial environments

-

Facilitates operator awareness and rapid fault identification

-

Supports multiple display communication standards

-

Field-replaceable module for ease of maintenance

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Bently Nevada 3500/93 Display Interface Module |

| Model Number | 3500/93 |

| Part Number | 135799-01 |

| Function | Interface between 3500 system and external display/HMI |

| Supported Display Protocols | ASCII, Modbus, proprietary Bently Nevada protocols |

| Communication Interface | Serial RS-232 / RS-485 (configurable) |

| Data Types Supported | Vibration, temperature, speed, alarm status, diagnostics |

| Diagnostic Indicators | LEDs for power, communication status, fault indication |

| Power Supply | Supplied via 3500 system rack backplane |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Certifications | CE, CSA, ATEX, IECEx (region dependent) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

Industry Applications

The 3500/93 Display Interface Module is used in industries where clear, real-time machinery data visualization is critical for operational safety and efficiency:

Oil & Gas: Real-time display of compressor and turbine condition for operators

Power Generation: Visualization of generator and turbine machinery health parameters

Petrochemical: Display of critical process equipment condition for preventive maintenance

Marine & Offshore: Operator interface for shaft and auxiliary machinery monitoring

Metals & Mining: Displaying vibration and temperature data for heavy equipment

Industrial Automation: Integration with plant HMIs for machinery protection status

Product Advantages

Enhanced Operator Awareness: Provides clear, real-time visualization of machinery health data

Flexible Display Compatibility: Supports multiple communication protocols and standards

Seamless System Integration: Designed for straightforward integration with 3500 series systems

Rugged and Reliable: Industrial design ensures consistent operation in demanding environments

Customizable Data Presentation: Configurable display mapping allows tailored operator views

Quick Diagnostics: LED indicators facilitate easy troubleshooting and system health checks

Field-Serviceable: Module can be replaced in the field to minimize downtime

Improved Maintenance Response: Enables rapid identification of faults and alarm conditions

Frequently Asked Questions (FAQ)

1. What is the primary purpose of the 3500/93 Display Interface Module?

It serves as the communication link between the 3500 system and external displays or HMIs, translating machine data into a readable format.

2. Which communication interfaces does the module support?

It supports serial RS-232 and RS-485 communication, configurable per system requirements.

3. What data types can be displayed through this module?

The module supports vibration, temperature, speed, alarm status, and diagnostic data.

4. Is the module compatible with standard display protocols?

Yes, it supports ASCII, Modbus, and proprietary Bently Nevada display protocols.

5. How is the module powered?

It receives power from the Bently Nevada 3500 system rack backplane.

6. Can the display data be customized?

Yes, display mapping is configurable to tailor information presentation for specific operator needs.

7. Is the module suitable for harsh industrial environments?

Yes, it is designed for operation between -30°C and +65°C in industrial settings.

8. Does the module include diagnostic indicators?

Yes, LED indicators provide information on power, communication status, and faults.

9. Is the module field-replaceable?

Yes, it is designed for easy field replacement to minimize downtime.

10. In which industries is this module commonly used?

Oil & gas, power generation, petrochemical, marine, mining, and industrial automation sectors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...