Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

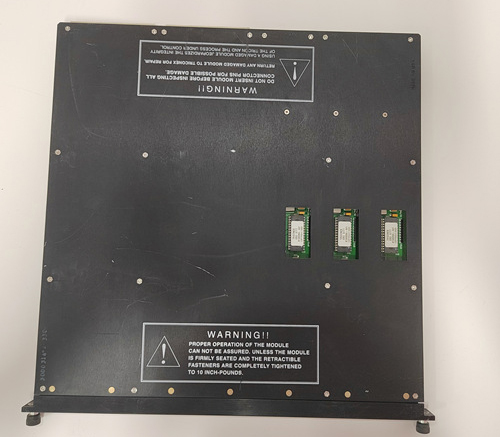

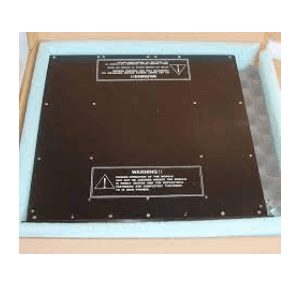

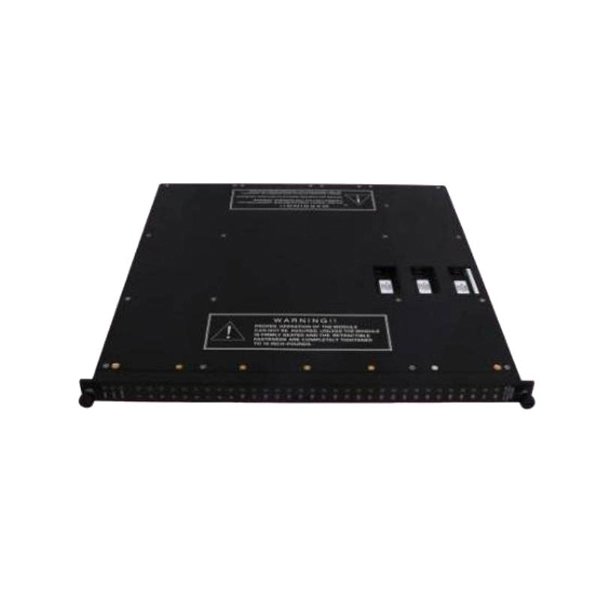

Triconex 8321 Control Module

Manufacturer:Triconex

Product Number:8321

Product Type:Control Module

Origin:USA

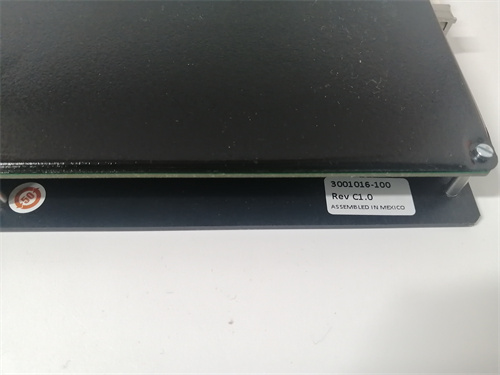

Dimensions:63 x 178 x 394 mm

Weight:3.3 kg

Views:91

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 8321 Control Module is an industrial-grade digital input module, specifically engineered for high-integrity and safety-critical applications. Part of the Triconex safety and critical control systems from Schneider Electric, it ensures reliable and deterministic acquisition of digital field inputs. The module plays a key role in facilitating safe shutdowns, alarms, interlocks, and process automation in sectors like oil & gas, chemicals, nuclear energy, and manufacturing.

What sets the 8321 apart is its robust performance in harsh industrial environments, its capacity for diagnostic feedback, and its ability to work seamlessly with redundant architectures. This module meets global safety certifications and can be integrated into SIL 3-rated Safety Instrumented Systems (SIS) with ease.

Product Specifications

| Parameter | Details |

| Model Number | Triconex 8321 |

| Product Type | Digital Input Module |

| Manufacturer | Schneider Electric (Triconex) |

| Input Type | Discrete (Digital) |

| Input Voltage | 24 VDC (Nominal) |

| Channels | 32 Digital Input Channels |

| Signal Detection | Dry Contact, Open Collector |

| Response Time | ≤ 10 ms |

| Redundancy | Supports Triple Modular Redundancy (TMR) |

| Built-in Diagnostics | Yes (channel health monitoring, fault detection) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| EMC Compliance | Meets IEC/EN 61000-6-2, IEC/EN 61000-6-4 |

| Shock/Vibration | IEC 60068-2 compliant |

| Safety Certification | SIL 3 (IEC 61508), TUV Certified |

| Mounting Type | DIN Rail or Backplane |

| Dimensions (L x W x H) | 63 x 178 x 394 mm |

| Weight | 3.3 kg |

Applications

The Triconex 8321 Control Module is utilized in various safety-critical industrial applications, including:

Process Control Systems: Providing reliable input signal acquisition in chemical, petrochemical, and pharmaceutical industries.

Power Generation: Ensuring accurate monitoring of safety inputs in power plants.

Oil and Gas: Supporting safety instrumented systems in offshore and onshore facilities.

Transportation Systems: Monitoring safety-critical inputs in railway and metro systems.

Manufacturing Automation: Acquiring input signals for automated production lines and machinery.

Advantages

High Reliability: Designed for continuous operation in safety-critical environments.

Fast Response Time: Ensures timely acquisition of input signals for rapid system response.

Robust Design: Operates reliably in a wide temperature range, suitable for harsh industrial conditions.

Compact Size: Small footprint allows for flexible installation in space-constrained environments.

Frequently Asked Questions (FAQs)

What is the primary function of the Triconex 8321 Control Module?

-

It acquires digital input signals from field devices for processing in safety instrumented systems.

-

Which systems are compatible with the 8321 module?

-

It is designed for use in Triconex safety instrumented systems (SIS).

-

What is the input voltage specification for the 8321?

-

It operates at 24 VDC.

-

What is the response time of the 8321 module?

-

It has a response time of 10 milliseconds.

-

What are the dimensions and weight of the 8321 module?

-

It measures 63 x 178 x 394 mm and weighs 3.3 kg.

-

What is the operating temperature range of the 8321?

-

It operates reliably within a temperature range of -20°C to +70°C.

-

Does the 8321 have diagnostic capabilities?

-

Yes, it includes features to monitor system health and detect faults.

-

Can the 8321 module be used in hazardous locations?

-

No, the 8321 is not suitable for hazardous locations requiring ATEX certification.

-

Is the 8321 module suitable for redundant system configurations?

-

Yes, it can be used in redundant configurations to enhance system reliability.

-

What maintenance is required for the 8321 module?

-

Regular inspection and testing are recommended to ensure optimal performance.

-

Triconex 8321 Control Module

Manufacturer:Triconex

Product Number:8321

Product Type:Control Module

Origin:USA

Dimensions:63 x 178 x 394 mm

Weight:3.3 kg

Views:91

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 8321 Control Module is an industrial-grade digital input module, specifically engineered for high-integrity and safety-critical applications. Part of the Triconex safety and critical control systems from Schneider Electric, it ensures reliable and deterministic acquisition of digital field inputs. The module plays a key role in facilitating safe shutdowns, alarms, interlocks, and process automation in sectors like oil & gas, chemicals, nuclear energy, and manufacturing.

What sets the 8321 apart is its robust performance in harsh industrial environments, its capacity for diagnostic feedback, and its ability to work seamlessly with redundant architectures. This module meets global safety certifications and can be integrated into SIL 3-rated Safety Instrumented Systems (SIS) with ease.

Product Specifications

| Parameter | Details |

| Model Number | Triconex 8321 |

| Product Type | Digital Input Module |

| Manufacturer | Schneider Electric (Triconex) |

| Input Type | Discrete (Digital) |

| Input Voltage | 24 VDC (Nominal) |

| Channels | 32 Digital Input Channels |

| Signal Detection | Dry Contact, Open Collector |

| Response Time | ≤ 10 ms |

| Redundancy | Supports Triple Modular Redundancy (TMR) |

| Built-in Diagnostics | Yes (channel health monitoring, fault detection) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| EMC Compliance | Meets IEC/EN 61000-6-2, IEC/EN 61000-6-4 |

| Shock/Vibration | IEC 60068-2 compliant |

| Safety Certification | SIL 3 (IEC 61508), TUV Certified |

| Mounting Type | DIN Rail or Backplane |

| Dimensions (L x W x H) | 63 x 178 x 394 mm |

| Weight | 3.3 kg |

Applications

The Triconex 8321 Control Module is utilized in various safety-critical industrial applications, including:

Process Control Systems: Providing reliable input signal acquisition in chemical, petrochemical, and pharmaceutical industries.

Power Generation: Ensuring accurate monitoring of safety inputs in power plants.

Oil and Gas: Supporting safety instrumented systems in offshore and onshore facilities.

Transportation Systems: Monitoring safety-critical inputs in railway and metro systems.

Manufacturing Automation: Acquiring input signals for automated production lines and machinery.

Advantages

High Reliability: Designed for continuous operation in safety-critical environments.

Fast Response Time: Ensures timely acquisition of input signals for rapid system response.

Robust Design: Operates reliably in a wide temperature range, suitable for harsh industrial conditions.

Compact Size: Small footprint allows for flexible installation in space-constrained environments.

Frequently Asked Questions (FAQs)

What is the primary function of the Triconex 8321 Control Module?

-

It acquires digital input signals from field devices for processing in safety instrumented systems.

-

Which systems are compatible with the 8321 module?

-

It is designed for use in Triconex safety instrumented systems (SIS).

-

What is the input voltage specification for the 8321?

-

It operates at 24 VDC.

-

What is the response time of the 8321 module?

-

It has a response time of 10 milliseconds.

-

What are the dimensions and weight of the 8321 module?

-

It measures 63 x 178 x 394 mm and weighs 3.3 kg.

-

What is the operating temperature range of the 8321?

-

It operates reliably within a temperature range of -20°C to +70°C.

-

Does the 8321 have diagnostic capabilities?

-

Yes, it includes features to monitor system health and detect faults.

-

Can the 8321 module be used in hazardous locations?

-

No, the 8321 is not suitable for hazardous locations requiring ATEX certification.

-

Is the 8321 module suitable for redundant system configurations?

-

Yes, it can be used in redundant configurations to enhance system reliability.

-

What maintenance is required for the 8321 module?

-

Regular inspection and testing are recommended to ensure optimal performance.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...