Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

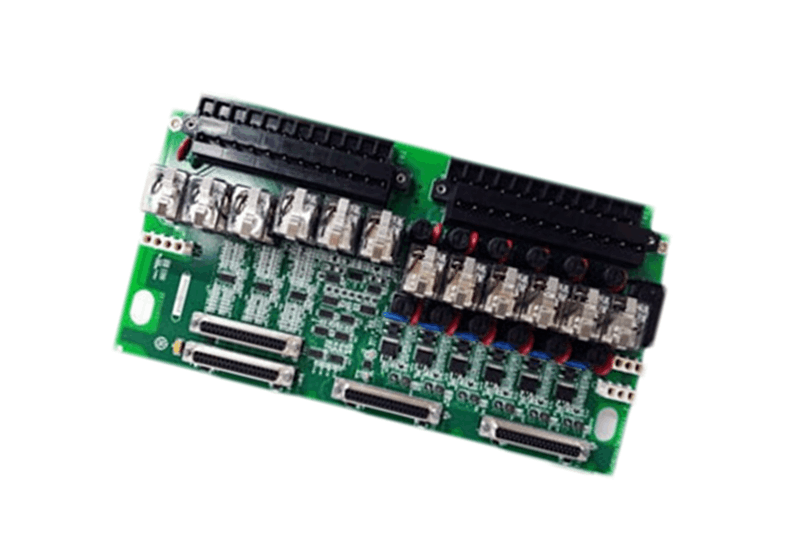

General Electric IS220PAOCHA1A Analog I/O Module

Manufacturer:GE

Product Number:IS220PAOCHA1A

Product Type:Analog I/O Module

Origin:USA

Dimensions:260 x 130 x 60 mm

Weight :1.2 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS220PAOCHA1A Analog I/O Module is a high-performance component designed for use within GE’s Mark VIe and Mark VIeS control systems. It provides precise analog input and output interfacing for process automation, ensuring accurate monitoring and control of critical industrial operations. This module is commonly used in power generation, oil & gas, and heavy industrial applications where reliable analog signal processing is required.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | IS220PAOCHA1A |

| Product Type | Analog I/O Module |

| Supported Signals | 4–20 mA current inputs, ±10 V analog inputs, 4–20 mA analog outputs |

| Number of Channels | 8 inputs / 4 outputs (typical) |

| Input Resolution | 16-bit |

| Output Resolution | 16-bit |

| Power Supply | 28–32 VDC |

| Operating Temperature | -20°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Communication Interface | Ethernet (Profinet-based) |

| Diagnostics | Self-diagnostics and fault detection |

| Dimensions | 260 x 130 x 60 mm |

| Weight | 1.2 kg |

Product Applications

Power Generation: Monitoring and controlling turbine analog signals.

Oil & Gas: Managing pipeline and refining plant analog process variables.

Industrial Automation: Supporting closed-loop control of analog equipment.

Chemical Processing: Maintaining accurate temperature, flow, and pressure regulation.

Heavy Machinery: Providing robust analog interfacing for motor and drive systems.

Product Advantages

High Accuracy: 16-bit resolution ensures precise signal conversion for demanding industrial processes.

Robust Design: Wide operating temperature range and rugged housing suitable for harsh environments.

Integrated Diagnostics: Built-in health monitoring reduces downtime and facilitates predictive maintenance.

Scalable Communication: Ethernet-based connectivity allows flexible integration into distributed control systems.

Reliability: Proven stability in mission-critical applications such as power plants and petrochemical facilities.

Ease of Integration: Direct compatibility with GE’s Mark VIe and Mark VIeS platforms simplifies installation.

FAQ

Q1: What type of analog signals does the IS220PAOCHA1A support?

A1: It supports standard 4–20 mA current signals and ±10 V voltage inputs, along with 4–20 mA analog outputs.

Q2: Can the module perform self-diagnostics?

A2: Yes, it features built-in self-diagnostics and error reporting for improved reliability.

Q3: What is the resolution of analog inputs and outputs?

A3: Both inputs and outputs are processed at 16-bit resolution.

Q4: Does the IS220PAOCHA1A support redundant configurations?

A4: Yes, it can be deployed in redundant Mark VIe control architectures for high availability.

Q5: How does the module communicate with the control system?

A5: It communicates using Ethernet-based Profinet protocols, ensuring fast and reliable data transfer.

Q6: Is hot-swapping supported by this module?

A6: No, power-down replacement is required to ensure safe operation.

Q7: What kind of fault detection is included?

A7: It provides open loop, short circuit, and range fault detection for analog channels.

Q8: Can the outputs drive both active and passive loads?

A8: Yes, the outputs are designed to handle both active and passive analog loads.

Q9: Is this module suitable for hazardous environments?

A9: Yes, with proper installation in certified enclosures, it meets industrial standards for hazardous zones.

Q10: What is the maximum update rate for signal processing?

A10: The module can process analog signals with update rates as fast as 10 ms, depending on configuration.

General Electric IS220PAOCHA1A Analog I/O Module

Manufacturer:GE

Product Number:IS220PAOCHA1A

Product Type:Analog I/O Module

Origin:USA

Dimensions:260 x 130 x 60 mm

Weight :1.2 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS220PAOCHA1A Analog I/O Module is a high-performance component designed for use within GE’s Mark VIe and Mark VIeS control systems. It provides precise analog input and output interfacing for process automation, ensuring accurate monitoring and control of critical industrial operations. This module is commonly used in power generation, oil & gas, and heavy industrial applications where reliable analog signal processing is required.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | IS220PAOCHA1A |

| Product Type | Analog I/O Module |

| Supported Signals | 4–20 mA current inputs, ±10 V analog inputs, 4–20 mA analog outputs |

| Number of Channels | 8 inputs / 4 outputs (typical) |

| Input Resolution | 16-bit |

| Output Resolution | 16-bit |

| Power Supply | 28–32 VDC |

| Operating Temperature | -20°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Communication Interface | Ethernet (Profinet-based) |

| Diagnostics | Self-diagnostics and fault detection |

| Dimensions | 260 x 130 x 60 mm |

| Weight | 1.2 kg |

Product Applications

Power Generation: Monitoring and controlling turbine analog signals.

Oil & Gas: Managing pipeline and refining plant analog process variables.

Industrial Automation: Supporting closed-loop control of analog equipment.

Chemical Processing: Maintaining accurate temperature, flow, and pressure regulation.

Heavy Machinery: Providing robust analog interfacing for motor and drive systems.

Product Advantages

High Accuracy: 16-bit resolution ensures precise signal conversion for demanding industrial processes.

Robust Design: Wide operating temperature range and rugged housing suitable for harsh environments.

Integrated Diagnostics: Built-in health monitoring reduces downtime and facilitates predictive maintenance.

Scalable Communication: Ethernet-based connectivity allows flexible integration into distributed control systems.

Reliability: Proven stability in mission-critical applications such as power plants and petrochemical facilities.

Ease of Integration: Direct compatibility with GE’s Mark VIe and Mark VIeS platforms simplifies installation.

FAQ

Q1: What type of analog signals does the IS220PAOCHA1A support?

A1: It supports standard 4–20 mA current signals and ±10 V voltage inputs, along with 4–20 mA analog outputs.

Q2: Can the module perform self-diagnostics?

A2: Yes, it features built-in self-diagnostics and error reporting for improved reliability.

Q3: What is the resolution of analog inputs and outputs?

A3: Both inputs and outputs are processed at 16-bit resolution.

Q4: Does the IS220PAOCHA1A support redundant configurations?

A4: Yes, it can be deployed in redundant Mark VIe control architectures for high availability.

Q5: How does the module communicate with the control system?

A5: It communicates using Ethernet-based Profinet protocols, ensuring fast and reliable data transfer.

Q6: Is hot-swapping supported by this module?

A6: No, power-down replacement is required to ensure safe operation.

Q7: What kind of fault detection is included?

A7: It provides open loop, short circuit, and range fault detection for analog channels.

Q8: Can the outputs drive both active and passive loads?

A8: Yes, the outputs are designed to handle both active and passive analog loads.

Q9: Is this module suitable for hazardous environments?

A9: Yes, with proper installation in certified enclosures, it meets industrial standards for hazardous zones.

Q10: What is the maximum update rate for signal processing?

A10: The module can process analog signals with update rates as fast as 10 ms, depending on configuration.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...