Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

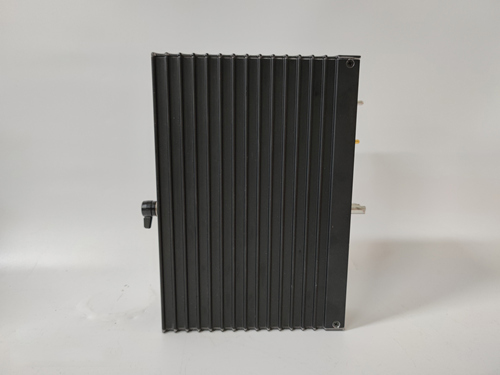

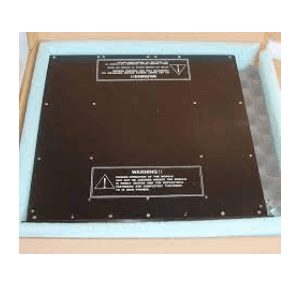

Triconex 3721N Analog Input Module

Manufacturer:Triconex

Product Number:3721N

Product Type:Analog Input Module

Origin:USA

Dimensions:185 x 135 x 45 mm

Weight:1.36 kg

Views:85

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 3721N Analog Input Module is a high-performance, safety-certified module designed for use in Triconex Safety Instrumented Systems (SIS). It provides accurate and reliable analog signal acquisition, making it a crucial component for industries requiring high safety and availability, such as oil and gas, chemical processing, power generation, and manufacturing.

This module is engineered to process analog signals from field devices, such as temperature sensors, pressure transducers, and flow meters. With fault tolerance, redundancy, and high precision, the Triconex 3721N ensures safe and efficient operation in critical industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 3721N |

| Type | Analog Input Module |

| Input Channels | 16 isolated analog input channels |

| Input Signal Range | 0-10V, 4-20mA, ±10V, ±20mA |

| Resolution | 12-bit or 16-bit (depending on configuration) |

| Accuracy | ±0.1% Full Scale |

| Input Impedance | >10 MΩ (voltage mode), 250Ω (current mode) |

| Isolation | 1500V channel-to-channel & channel-to-ground |

| Sampling Rate | Configurable, up to 10 kHz |

| Communication | Integrated with Triconex systems via TMR |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

| Power Consumption | 5W typical |

| Installation | Rack-mounted (Triconex chassis) |

| Dimensions (W x H x D) | 185 x 135 x 45 mm |

| Weight | 1.36 kg |

Applications of Triconex 3721N

The Triconex 3721N module is widely used in safety-critical applications that require precise analog signal monitoring and processing.

Oil & Gas Industry: Used in emergency shutdown (ESD) systems, burner management systems (BMS), and pipeline monitoring.

Power Generation: Essential in turbine control, boiler protection, and nuclear plant safety systems.

Chemical & Petrochemical: Provides real-time data acquisition for process safety applications.

Water Treatment Plants: Ensures safe and efficient operation of pumps, valves, and chemical dosing systems.

Pharmaceutical Manufacturing: Enables precise monitoring of temperature, pressure, and humidity for compliance with industry standards.

Railway & Transportation: Supports automation and safety monitoring in railway signaling and traffic management.

Advantages of Triconex 3721N

Triple Modular Redundancy (TMR) Support: Provides fault tolerance and high system reliability.

High Accuracy and Precision: Ensures reliable measurement and real-time process monitoring.

Channel Isolation: Protects against signal interference and electrical surges.

Flexible Input Configuration: Supports both voltage and current input signals.

Wide Operating Temperature Range: Designed for extreme industrial environments.

Seamless Integration with Triconex Systems: Ensures easy implementation in existing SIS networks.

Long Lifecycle and Low Maintenance: Built to last in critical industrial applications.

Certified for Safety Standards: Meets IEC 61508 SIL 3 and other international safety certifications.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Triconex 3721N module?

The Triconex 3721N is an analog input module designed for safety-critical applications, processing and monitoring signals from field sensors.

-

What types of signals can the 3721N process?

It supports 0-10V, 4-20mA, ±10V, and ±20mA analog signals, making it versatile for different industrial applications.

-

How does the Triconex 3721N enhance system safety?

It utilizes Triple Modular Redundancy (TMR), which ensures fault tolerance and system reliability in industrial safety applications.

-

Can the module be used in hazardous environments?

Yes, it is certified for use in hazardous industrial settings, including oil refineries, chemical plants, and power stations.

-

Does the 3721N module require special software for configuration?

Yes, it requires Triconex proprietary configuration tools for setup, calibration, and diagnostics.

-

What is the power consumption of the 3721N module?

It has a typical power consumption of 5W, ensuring efficient energy usage.

-

What kind of protection does the module offer against electrical interference?

It provides 1500V isolation between channels and ground, minimizing signal interference and improving reliability.

-

How frequently can the module sample data?

The sampling rate is configurable up to 10 kHz, allowing real-time data acquisition for critical processes.

-

How is the Triconex 3721N installed in a system?

It is a rack-mounted module designed for installation in Triconex chassis, ensuring a secure and stable connection.

-

Is the Triconex 3721N compatible with older Triconex systems?

Yes, it is backward compatible with many previous Triconex safety systems, allowing seamless upgrades.

Triconex 3721N Analog Input Module

Manufacturer:Triconex

Product Number:3721N

Product Type:Analog Input Module

Origin:USA

Dimensions:185 x 135 x 45 mm

Weight:1.36 kg

Views:85

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 3721N Analog Input Module is a high-performance, safety-certified module designed for use in Triconex Safety Instrumented Systems (SIS). It provides accurate and reliable analog signal acquisition, making it a crucial component for industries requiring high safety and availability, such as oil and gas, chemical processing, power generation, and manufacturing.

This module is engineered to process analog signals from field devices, such as temperature sensors, pressure transducers, and flow meters. With fault tolerance, redundancy, and high precision, the Triconex 3721N ensures safe and efficient operation in critical industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 3721N |

| Type | Analog Input Module |

| Input Channels | 16 isolated analog input channels |

| Input Signal Range | 0-10V, 4-20mA, ±10V, ±20mA |

| Resolution | 12-bit or 16-bit (depending on configuration) |

| Accuracy | ±0.1% Full Scale |

| Input Impedance | >10 MΩ (voltage mode), 250Ω (current mode) |

| Isolation | 1500V channel-to-channel & channel-to-ground |

| Sampling Rate | Configurable, up to 10 kHz |

| Communication | Integrated with Triconex systems via TMR |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

| Power Consumption | 5W typical |

| Installation | Rack-mounted (Triconex chassis) |

| Dimensions (W x H x D) | 185 x 135 x 45 mm |

| Weight | 1.36 kg |

Applications of Triconex 3721N

The Triconex 3721N module is widely used in safety-critical applications that require precise analog signal monitoring and processing.

Oil & Gas Industry: Used in emergency shutdown (ESD) systems, burner management systems (BMS), and pipeline monitoring.

Power Generation: Essential in turbine control, boiler protection, and nuclear plant safety systems.

Chemical & Petrochemical: Provides real-time data acquisition for process safety applications.

Water Treatment Plants: Ensures safe and efficient operation of pumps, valves, and chemical dosing systems.

Pharmaceutical Manufacturing: Enables precise monitoring of temperature, pressure, and humidity for compliance with industry standards.

Railway & Transportation: Supports automation and safety monitoring in railway signaling and traffic management.

Advantages of Triconex 3721N

Triple Modular Redundancy (TMR) Support: Provides fault tolerance and high system reliability.

High Accuracy and Precision: Ensures reliable measurement and real-time process monitoring.

Channel Isolation: Protects against signal interference and electrical surges.

Flexible Input Configuration: Supports both voltage and current input signals.

Wide Operating Temperature Range: Designed for extreme industrial environments.

Seamless Integration with Triconex Systems: Ensures easy implementation in existing SIS networks.

Long Lifecycle and Low Maintenance: Built to last in critical industrial applications.

Certified for Safety Standards: Meets IEC 61508 SIL 3 and other international safety certifications.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Triconex 3721N module?

The Triconex 3721N is an analog input module designed for safety-critical applications, processing and monitoring signals from field sensors.

-

What types of signals can the 3721N process?

It supports 0-10V, 4-20mA, ±10V, and ±20mA analog signals, making it versatile for different industrial applications.

-

How does the Triconex 3721N enhance system safety?

It utilizes Triple Modular Redundancy (TMR), which ensures fault tolerance and system reliability in industrial safety applications.

-

Can the module be used in hazardous environments?

Yes, it is certified for use in hazardous industrial settings, including oil refineries, chemical plants, and power stations.

-

Does the 3721N module require special software for configuration?

Yes, it requires Triconex proprietary configuration tools for setup, calibration, and diagnostics.

-

What is the power consumption of the 3721N module?

It has a typical power consumption of 5W, ensuring efficient energy usage.

-

What kind of protection does the module offer against electrical interference?

It provides 1500V isolation between channels and ground, minimizing signal interference and improving reliability.

-

How frequently can the module sample data?

The sampling rate is configurable up to 10 kHz, allowing real-time data acquisition for critical processes.

-

How is the Triconex 3721N installed in a system?

It is a rack-mounted module designed for installation in Triconex chassis, ensuring a secure and stable connection.

-

Is the Triconex 3721N compatible with older Triconex systems?

Yes, it is backward compatible with many previous Triconex safety systems, allowing seamless upgrades.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...