Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

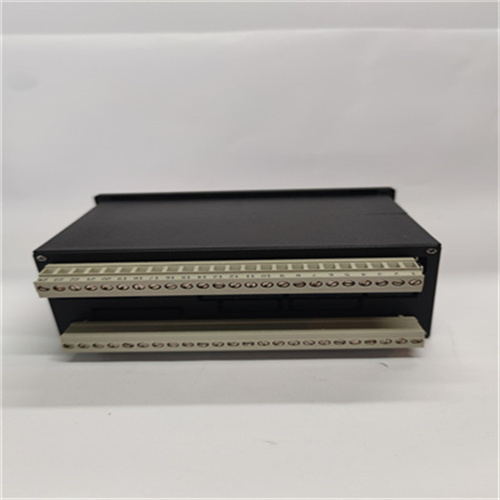

Woodward 5439-986 Chassis

Manufacturer:Woodward

Product Number:5439-986

Condition:Chassis

Origin:USA

Dimensions:200 x 150 x 120 mm

Weight:1.5kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

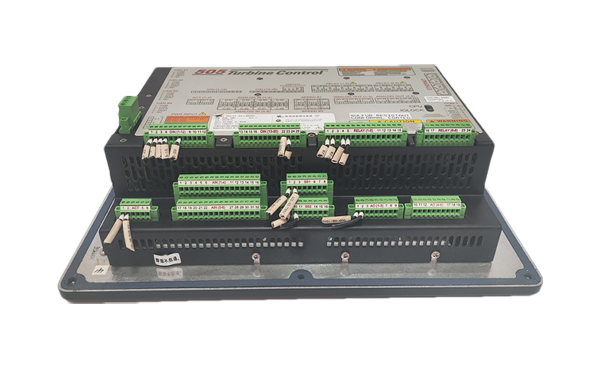

The Woodward 5439-986 is a high-performance digital control module specifically designed for industrial turbine and engine applications. As part of Woodward’s advanced control solutions, this unit integrates robust signal processing, advanced control algorithms, and reliable communication interfaces to ensure precise and stable management of complex rotating equipment.

Built to meet the rigorous demands of power generation and mechanical drive systems, the 5439-986 module plays a crucial role in the automatic regulation of fuel, air, and other process variables to ensure operational efficiency, emissions compliance, and long-term system stability. With its proven track record in various industrial environments, the 5439-986 is highly regarded for both new installations and retrofit projects.

Product Advantages

High Reliability: Designed for continuous operation in critical environments with robust protective features.

Flexible Configuration: Supports a range of I/O combinations for different turbine or engine configurations.

Real-Time Processing: Rapid control response enables stable performance even under load transients.

Long Lifecycle Support: Backed by Woodward’s long-term availability of components and service.

Industrial Communication Protocols: Supports Modbus, CAN, and other standard interfaces for seamless integration.

Diagnostic Capability: Integrated diagnostics help in predictive maintenance and reduce unplanned downtimes.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | Woodward 5439-986 |

| Product Type | Turbine/Engine Digital Control Module |

| Input Voltage | 18 – 32 VDC |

| Power Consumption | 15 W |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Communication Ports | RS-232, RS-485, CAN, Ethernet |

| Digital Inputs | 16 isolated channels |

| Analog Inputs | 8 channels, configurable (4–20 mA, 0–10V) |

| Analog Outputs | 4 channels, programmable |

| Dimensions | 200 x 150 x 120 mm |

| Weight | 1.5kg |

| Mounting | Panel or rack-mounted |

| Compliance | CE, RoHS, UL, CSA (depends on version) |

Product Applications

Gas and Steam Turbines: Regulates fuel flow, manages startup/shutdown sequences, and stabilizes turbine performance.

Industrial Diesel and Gas Engines: Controls air-fuel ratio, ignition timing, and exhaust emissions.

Compressor Stations: Ensures reliable control of engine-compressor systems in oil and gas pipelines.

Power Generation Units: Maintains stable frequency and voltage in generator sets.

Cogeneration and CHP Plants: Optimizes energy output and reduces waste.

Marine Propulsion Systems: Helps in controlling propulsion turbines or large auxiliary engines.

Installation Instructions

Unpack and Inspect: Ensure the module is free from damage and that all accessories are included.

Mounting: Secure the unit in a clean, dry, and vibration-free enclosure using the designated panel or rack mounting system.

Wiring: Connect all input and output wiring as per the Woodward wiring diagram. Use shielded cables for signal integrity.

Power Connection: Apply 24VDC regulated power source. Confirm polarity and grounding per installation manual.

Communication Setup: Configure ports and communication parameters through Woodward’s Toolbox or GAP software.

Functional Testing: Perform I/O tests and simulate signals to verify correct responses.

Commissioning: Load the control logic, perform calibration, and conduct a full operational check before going live.

Woodward 5439-986 Chassis

Manufacturer:Woodward

Product Number:5439-986

Condition:Chassis

Origin:USA

Dimensions:200 x 150 x 120 mm

Weight:1.5kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 5439-986 is a high-performance digital control module specifically designed for industrial turbine and engine applications. As part of Woodward’s advanced control solutions, this unit integrates robust signal processing, advanced control algorithms, and reliable communication interfaces to ensure precise and stable management of complex rotating equipment.

Built to meet the rigorous demands of power generation and mechanical drive systems, the 5439-986 module plays a crucial role in the automatic regulation of fuel, air, and other process variables to ensure operational efficiency, emissions compliance, and long-term system stability. With its proven track record in various industrial environments, the 5439-986 is highly regarded for both new installations and retrofit projects.

Product Advantages

High Reliability: Designed for continuous operation in critical environments with robust protective features.

Flexible Configuration: Supports a range of I/O combinations for different turbine or engine configurations.

Real-Time Processing: Rapid control response enables stable performance even under load transients.

Long Lifecycle Support: Backed by Woodward’s long-term availability of components and service.

Industrial Communication Protocols: Supports Modbus, CAN, and other standard interfaces for seamless integration.

Diagnostic Capability: Integrated diagnostics help in predictive maintenance and reduce unplanned downtimes.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | Woodward 5439-986 |

| Product Type | Turbine/Engine Digital Control Module |

| Input Voltage | 18 – 32 VDC |

| Power Consumption | 15 W |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Communication Ports | RS-232, RS-485, CAN, Ethernet |

| Digital Inputs | 16 isolated channels |

| Analog Inputs | 8 channels, configurable (4–20 mA, 0–10V) |

| Analog Outputs | 4 channels, programmable |

| Dimensions | 200 x 150 x 120 mm |

| Weight | 1.5kg |

| Mounting | Panel or rack-mounted |

| Compliance | CE, RoHS, UL, CSA (depends on version) |

Product Applications

Gas and Steam Turbines: Regulates fuel flow, manages startup/shutdown sequences, and stabilizes turbine performance.

Industrial Diesel and Gas Engines: Controls air-fuel ratio, ignition timing, and exhaust emissions.

Compressor Stations: Ensures reliable control of engine-compressor systems in oil and gas pipelines.

Power Generation Units: Maintains stable frequency and voltage in generator sets.

Cogeneration and CHP Plants: Optimizes energy output and reduces waste.

Marine Propulsion Systems: Helps in controlling propulsion turbines or large auxiliary engines.

Installation Instructions

Unpack and Inspect: Ensure the module is free from damage and that all accessories are included.

Mounting: Secure the unit in a clean, dry, and vibration-free enclosure using the designated panel or rack mounting system.

Wiring: Connect all input and output wiring as per the Woodward wiring diagram. Use shielded cables for signal integrity.

Power Connection: Apply 24VDC regulated power source. Confirm polarity and grounding per installation manual.

Communication Setup: Configure ports and communication parameters through Woodward’s Toolbox or GAP software.

Functional Testing: Perform I/O tests and simulate signals to verify correct responses.

Commissioning: Load the control logic, perform calibration, and conduct a full operational check before going live.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...