Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

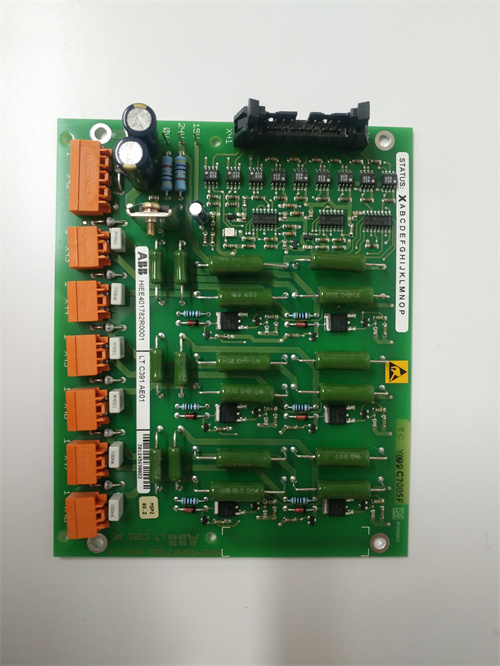

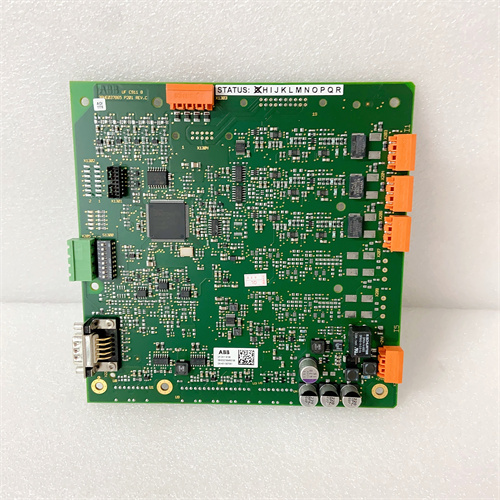

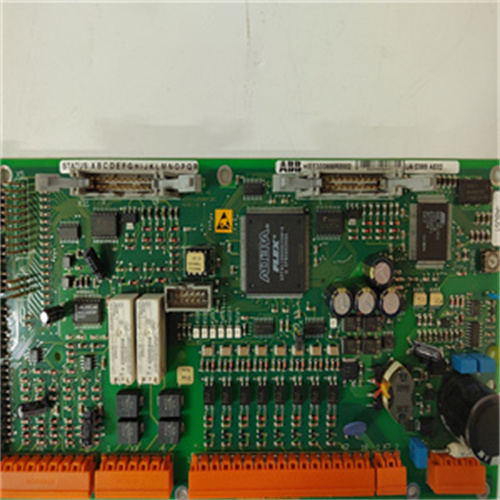

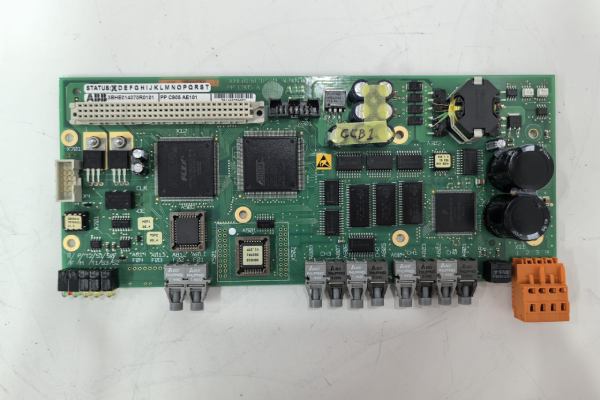

ABB CM588-CN 1SAP172800R0001 Communication Module

Manufacturer:ABB

Product Number:CM588-CN 1SAP172800R0001

Product Type:Communication Module

Origin:Sweden

Dimensions:62 x 135 x 28 mm

Weight:0.134 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB CM588-CN communication module (Order Code: 1SAP172800R0001) is an advanced fieldbus interface module designed specifically for the ABB AC500 series of programmable logic controllers (PLCs). This model is particularly engineered to support CANopen communication, allowing seamless integration between the PLC and a wide array of CANopen-enabled field devices such as I/O units, motor controllers, encoders, and sensors.

As an integral component in modern industrial networks, the CM588-CN provides deterministic data exchange, precise device coordination, and simplified diagnostics—all essential for robust control in distributed automation systems. Thanks to ABB’s Automation Builder software, the module can be easily configured and managed, ensuring efficient commissioning and maintenance workflows.

The module is housed in a compact DIN-rail-mounted enclosure, making it suitable for tight industrial control cabinets. Its support for master functionality allows it to control multiple CANopen devices within a single network, expanding the flexibility and scalability of automation projects.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | CM588-CN Communication Module |

| Product Code | 1SAP172800R0001 |

| Manufacturer | ABB |

| Series | AC500 PLC Series |

| Communication Protocol | CANopen (CAN 2.0 B) |

| Bus Type | CANopen (master functionality) |

| Baud Rate | Up to 1 Mbps |

| Max Devices | Supports up to 127 CANopen slave nodes |

| Connector Type | 5-pin terminal (CAN_H, CAN_L, GND, SHIELD, +24V) |

| Configuration Tool | ABB Automation Builder |

| Firmware Upgrade | Via SD card or engineering software |

| Power Supply Voltage | Supplied by AC500 base unit (typically 24 V DC) |

| Current Consumption | Approx. 100 mA @ 24 V DC |

| Diagnostics | Bus status, node status, error logging |

| Protection Class | IP20 |

| Mounting Method | DIN rail (35 mm standard rail) |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Dimensions (W x H x D) | 62 x 135 x 28 mm |

| Weight | 0.134 kg |

| Certifications | CE, RoHS, EAC, UL (cULus) |

Product Applications

The CM588-CN is designed to serve in high-performance industrial control systems that require real-time, decentralized field communication via CANopen. It is widely deployed in various sectors:

Factory Automation

Facilitates communication between a central PLC and machine-level devices like encoders, sensors, and valve terminals.

Material Handling Systems

Integrates with drives and motor controllers for conveyor belts, sorters, and lift systems.

Renewable Energy

Connects wind turbine subsystems and photovoltaic control equipment with central controllers.

Packaging Machinery

Offers fast coordination between control units, actuators, and feedback devices.

Mobile Machinery

Used in off-road vehicles and cranes for communication between ECUs and sensors.

-

Enhances modularity in plants needing distributed control such as in water treatment or food processing.

Product Advantages

High Network Capacity

Supports up to 127 CANopen slave nodes, enabling complex system integration.

Master Control Functionality

Acts as a CANopen master, enabling centralized control and easy network expansion.

Robust Physical Layer

Built to operate in demanding industrial environments with high immunity to noise and vibration.

Integrated Diagnostics

Real-time status and fault monitoring help reduce downtime and ease troubleshooting.

Tool-Assisted Configuration

Compatible with ABB Automation Builder, simplifying engineering tasks and commissioning.

Compact Industrial Design

DIN-rail mountable with a small footprint suitable for dense control panel layouts.

Reliable CANopen Protocol Support

Fully compliant with CiA DS301 and related CANopen standards.

Frequently Asked Questions (FAQ)

Q: What is the function of the CM588-CN module?

A: It provides a CANopen interface for AC500 PLCs to communicate with field devices like drives, I/O modules, and sensors.

Q: Can this module function as a CANopen slave?

A: No, the CM588-CN is designed to operate solely as a CANopen master.

Q: What is the maximum supported baud rate?

A: The module supports CANopen communication speeds up to 1 Mbps.

Q: How many devices can it connect to on the CANopen bus?

A: It can manage communication with up to 127 slave nodes on a single CANopen network.

Q: What software is used for configuration?

A: ABB’s Automation Builder engineering suite is used to configure and diagnose the module.

Q: How is the module powered?

A: It receives power via the PLC’s base module, typically 24 V DC.

Q: Can the module be replaced without powering down the system?

A: No, hot-swapping is not supported. The system must be powered down for module replacement.

Q: Is termination required on the CANopen line?

A: Yes, standard CANopen practice requires 120-ohm termination resistors at both ends of the network.

Q: What kind of diagnostics does it offer?

A: The module provides bus status, node health, and error logging, accessible through software tools.

Q: What is the difference between CM588-CN and CM588-DP?

A: CM588-CN supports CANopen, while CM588-DP is for PROFIBUS DP communication.

ABB CM588-CN 1SAP172800R0001 Communication Module

Manufacturer:ABB

Product Number:CM588-CN 1SAP172800R0001

Product Type:Communication Module

Origin:Sweden

Dimensions:62 x 135 x 28 mm

Weight:0.134 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB CM588-CN communication module (Order Code: 1SAP172800R0001) is an advanced fieldbus interface module designed specifically for the ABB AC500 series of programmable logic controllers (PLCs). This model is particularly engineered to support CANopen communication, allowing seamless integration between the PLC and a wide array of CANopen-enabled field devices such as I/O units, motor controllers, encoders, and sensors.

As an integral component in modern industrial networks, the CM588-CN provides deterministic data exchange, precise device coordination, and simplified diagnostics—all essential for robust control in distributed automation systems. Thanks to ABB’s Automation Builder software, the module can be easily configured and managed, ensuring efficient commissioning and maintenance workflows.

The module is housed in a compact DIN-rail-mounted enclosure, making it suitable for tight industrial control cabinets. Its support for master functionality allows it to control multiple CANopen devices within a single network, expanding the flexibility and scalability of automation projects.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | CM588-CN Communication Module |

| Product Code | 1SAP172800R0001 |

| Manufacturer | ABB |

| Series | AC500 PLC Series |

| Communication Protocol | CANopen (CAN 2.0 B) |

| Bus Type | CANopen (master functionality) |

| Baud Rate | Up to 1 Mbps |

| Max Devices | Supports up to 127 CANopen slave nodes |

| Connector Type | 5-pin terminal (CAN_H, CAN_L, GND, SHIELD, +24V) |

| Configuration Tool | ABB Automation Builder |

| Firmware Upgrade | Via SD card or engineering software |

| Power Supply Voltage | Supplied by AC500 base unit (typically 24 V DC) |

| Current Consumption | Approx. 100 mA @ 24 V DC |

| Diagnostics | Bus status, node status, error logging |

| Protection Class | IP20 |

| Mounting Method | DIN rail (35 mm standard rail) |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Dimensions (W x H x D) | 62 x 135 x 28 mm |

| Weight | 0.134 kg |

| Certifications | CE, RoHS, EAC, UL (cULus) |

Product Applications

The CM588-CN is designed to serve in high-performance industrial control systems that require real-time, decentralized field communication via CANopen. It is widely deployed in various sectors:

Factory Automation

Facilitates communication between a central PLC and machine-level devices like encoders, sensors, and valve terminals.

Material Handling Systems

Integrates with drives and motor controllers for conveyor belts, sorters, and lift systems.

Renewable Energy

Connects wind turbine subsystems and photovoltaic control equipment with central controllers.

Packaging Machinery

Offers fast coordination between control units, actuators, and feedback devices.

Mobile Machinery

Used in off-road vehicles and cranes for communication between ECUs and sensors.

-

Enhances modularity in plants needing distributed control such as in water treatment or food processing.

Product Advantages

High Network Capacity

Supports up to 127 CANopen slave nodes, enabling complex system integration.

Master Control Functionality

Acts as a CANopen master, enabling centralized control and easy network expansion.

Robust Physical Layer

Built to operate in demanding industrial environments with high immunity to noise and vibration.

Integrated Diagnostics

Real-time status and fault monitoring help reduce downtime and ease troubleshooting.

Tool-Assisted Configuration

Compatible with ABB Automation Builder, simplifying engineering tasks and commissioning.

Compact Industrial Design

DIN-rail mountable with a small footprint suitable for dense control panel layouts.

Reliable CANopen Protocol Support

Fully compliant with CiA DS301 and related CANopen standards.

Frequently Asked Questions (FAQ)

Q: What is the function of the CM588-CN module?

A: It provides a CANopen interface for AC500 PLCs to communicate with field devices like drives, I/O modules, and sensors.

Q: Can this module function as a CANopen slave?

A: No, the CM588-CN is designed to operate solely as a CANopen master.

Q: What is the maximum supported baud rate?

A: The module supports CANopen communication speeds up to 1 Mbps.

Q: How many devices can it connect to on the CANopen bus?

A: It can manage communication with up to 127 slave nodes on a single CANopen network.

Q: What software is used for configuration?

A: ABB’s Automation Builder engineering suite is used to configure and diagnose the module.

Q: How is the module powered?

A: It receives power via the PLC’s base module, typically 24 V DC.

Q: Can the module be replaced without powering down the system?

A: No, hot-swapping is not supported. The system must be powered down for module replacement.

Q: Is termination required on the CANopen line?

A: Yes, standard CANopen practice requires 120-ohm termination resistors at both ends of the network.

Q: What kind of diagnostics does it offer?

A: The module provides bus status, node health, and error logging, accessible through software tools.

Q: What is the difference between CM588-CN and CM588-DP?

A: CM588-CN supports CANopen, while CM588-DP is for PROFIBUS DP communication.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...