Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

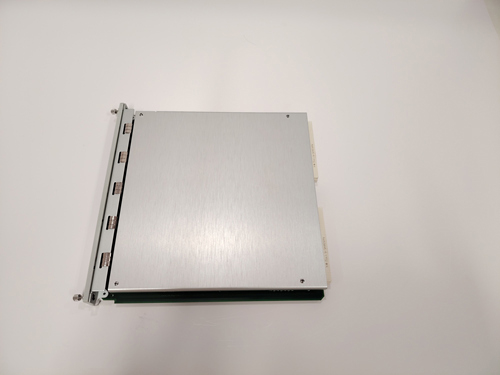

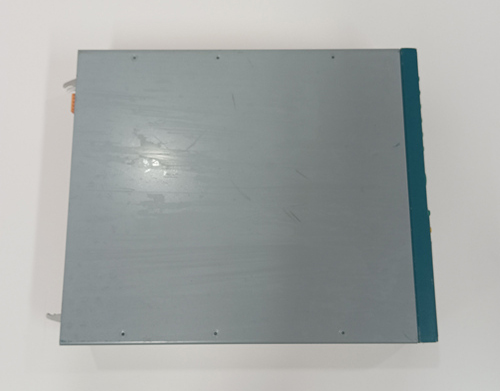

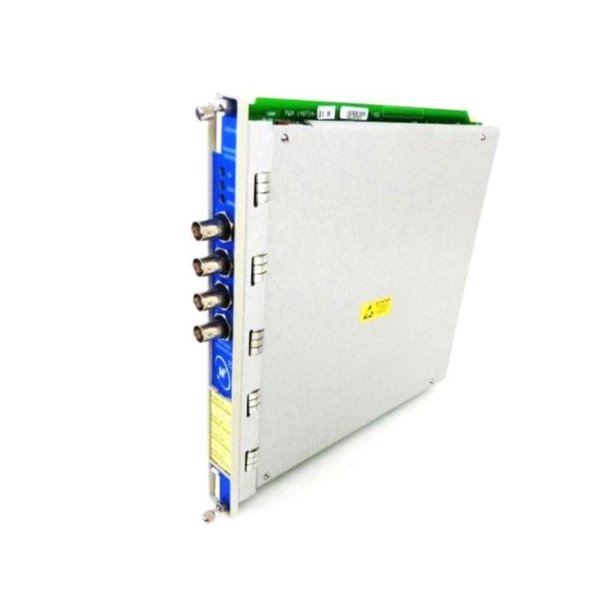

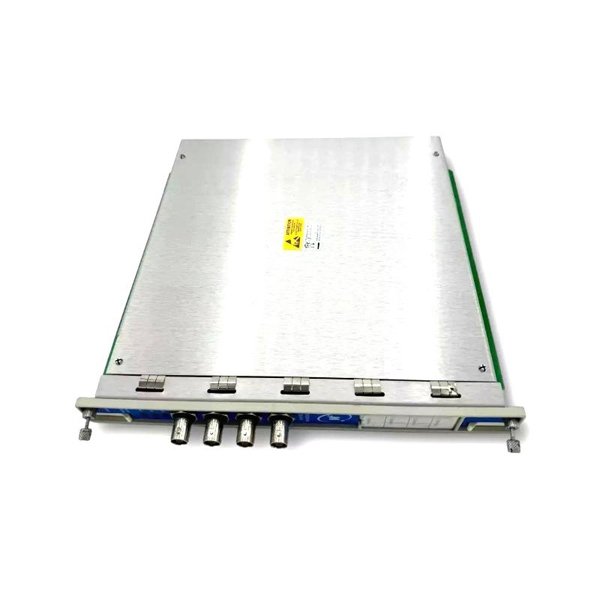

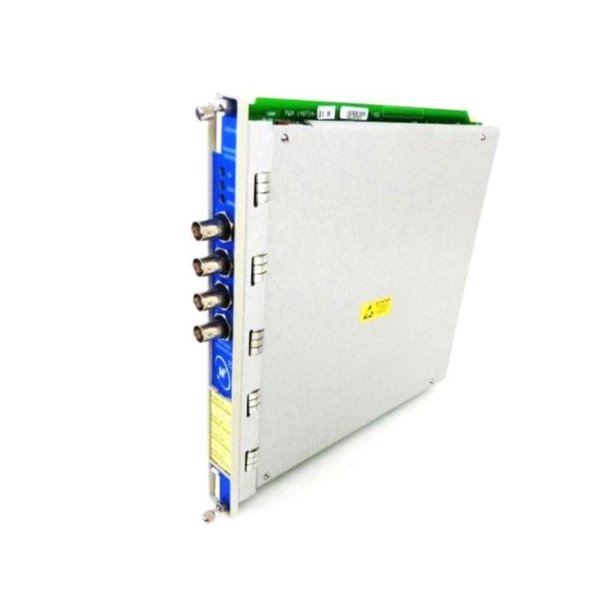

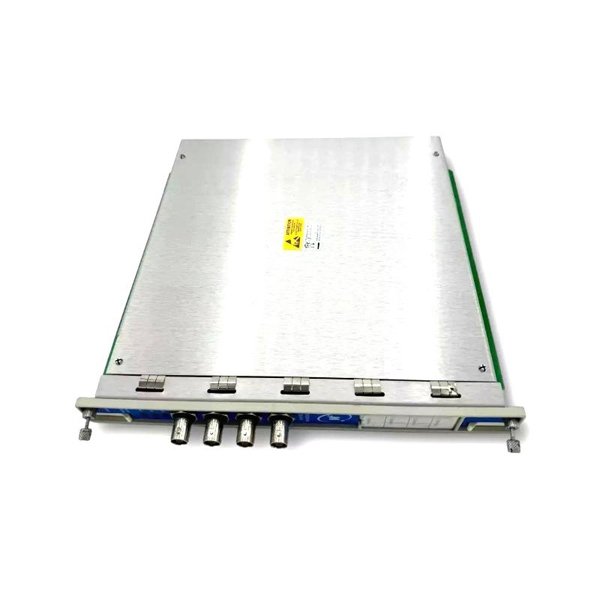

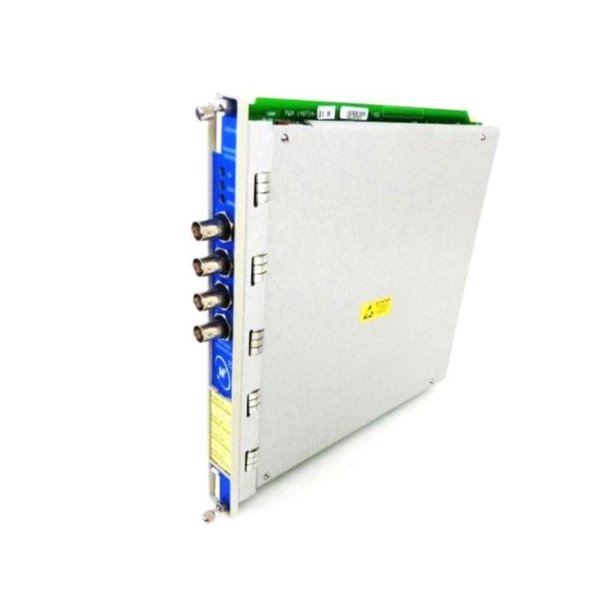

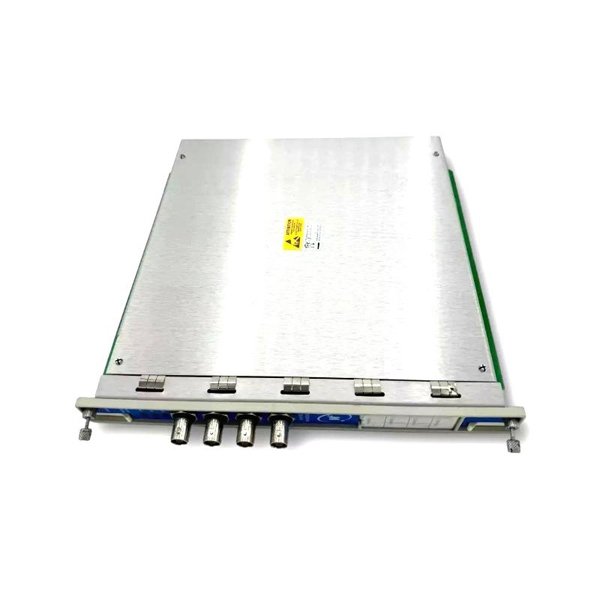

Bently Nevada 3500/40M 140734-01+126615-01 Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40M 140734-01+126615-

Product Type:Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M Proximitor Monitor is a four-channel monitoring module designed to accept inputs from proximity transducers, condition vibration and position signals, and compare these signals to user-configured alarm setpoints. It supports multiple measurement functions including radial vibration, thrust position, differential expansion, eccentricity, and REBAM. This model combines robust machinery protection with detailed diagnostic information for operations and maintenance teams.

Technical Specifications

| Parameter | Specification |

|---|---|

| Channels | 4 |

| Input Type | Proximity transducer signals |

| Sensitivity | 3.94 mV/μm or 7.87 mV/μm (varies by function) |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 Vdc |

| Frequency Response | Function-dependent, programmable |

| Operating Temperature | -30°C to +65°C (varies by I/O type) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | FCC, CE, RoHS, ABS, DNV GL |

| Hazardous Area Approvals | CSA, ATEX, IECEx |

Applications

-

Continuous machinery vibration and position monitoring

-

Turbomachinery radial vibration detection

-

Thrust position and axial displacement measurement

-

Shaft eccentricity evaluation

-

Rotor blade and element analysis with REBAM

-

Alarm-based machinery shutdown or protective action

Advantages

-

Multi-function monitoring in a single module

-

High accuracy and wide programmable range

-

Fully configurable with 3500 Rack Configuration Software

-

Compatible with hazardous area applications

-

Real-time machinery protection and diagnostic capability

-

Rugged design for harsh industrial environments

Frequently Asked Questions

Q1: What does the 3500/40M monitor measure?

A1: It measures radial vibration, thrust position, differential expansion, eccentricity, and REBAM parameters.

Q2: How many channels does it have?

A2: It has four independent channels, configurable in pairs.

Q3: Can it operate in hazardous areas?

A3: Yes, it has CSA, ATEX, and IECEx approvals for use in Zone 2/Class I Division 2 environments.

Q4: How is the module configured?

A4: Using the Bently Nevada 3500 Rack Configuration Software.

Q5: What is the accuracy of vibration measurements?

A5: Typically within ±0.33% of full scale.

Q6: Does it support buffered transducer outputs?

A6: Yes, each channel provides a coaxial connector for buffered output.

Q7: What is the operating temperature range?

A7: From -30°C to +65°C, depending on the I/O module type.

Q8: Is REBAM supported in all channels?

A8: Yes, but it requires specific firmware and software revisions.

Q9: How are alarms set?

A9: Alert and danger setpoints are programmed via configuration software.

Q10: Can the monitor perform multiple functions at once?

A10: Yes, channels can be programmed in pairs to perform up to two functions simultaneously.

Bently Nevada 3500/40M 140734-01+126615-01 Proximitor Monitor

Manufacturer:Bently Nevada

Product Number:3500/40M 140734-01+126615-

Product Type:Proximitor Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/40M Proximitor Monitor is a four-channel monitoring module designed to accept inputs from proximity transducers, condition vibration and position signals, and compare these signals to user-configured alarm setpoints. It supports multiple measurement functions including radial vibration, thrust position, differential expansion, eccentricity, and REBAM. This model combines robust machinery protection with detailed diagnostic information for operations and maintenance teams.

Technical Specifications

| Parameter | Specification |

|---|---|

| Channels | 4 |

| Input Type | Proximity transducer signals |

| Sensitivity | 3.94 mV/μm or 7.87 mV/μm (varies by function) |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 Vdc |

| Frequency Response | Function-dependent, programmable |

| Operating Temperature | -30°C to +65°C (varies by I/O type) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | FCC, CE, RoHS, ABS, DNV GL |

| Hazardous Area Approvals | CSA, ATEX, IECEx |

Applications

-

Continuous machinery vibration and position monitoring

-

Turbomachinery radial vibration detection

-

Thrust position and axial displacement measurement

-

Shaft eccentricity evaluation

-

Rotor blade and element analysis with REBAM

-

Alarm-based machinery shutdown or protective action

Advantages

-

Multi-function monitoring in a single module

-

High accuracy and wide programmable range

-

Fully configurable with 3500 Rack Configuration Software

-

Compatible with hazardous area applications

-

Real-time machinery protection and diagnostic capability

-

Rugged design for harsh industrial environments

Frequently Asked Questions

Q1: What does the 3500/40M monitor measure?

A1: It measures radial vibration, thrust position, differential expansion, eccentricity, and REBAM parameters.

Q2: How many channels does it have?

A2: It has four independent channels, configurable in pairs.

Q3: Can it operate in hazardous areas?

A3: Yes, it has CSA, ATEX, and IECEx approvals for use in Zone 2/Class I Division 2 environments.

Q4: How is the module configured?

A4: Using the Bently Nevada 3500 Rack Configuration Software.

Q5: What is the accuracy of vibration measurements?

A5: Typically within ±0.33% of full scale.

Q6: Does it support buffered transducer outputs?

A6: Yes, each channel provides a coaxial connector for buffered output.

Q7: What is the operating temperature range?

A7: From -30°C to +65°C, depending on the I/O module type.

Q8: Is REBAM supported in all channels?

A8: Yes, but it requires specific firmware and software revisions.

Q9: How are alarms set?

A9: Alert and danger setpoints are programmed via configuration software.

Q10: Can the monitor perform multiple functions at once?

A10: Yes, channels can be programmed in pairs to perform up to two functions simultaneously.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...