Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

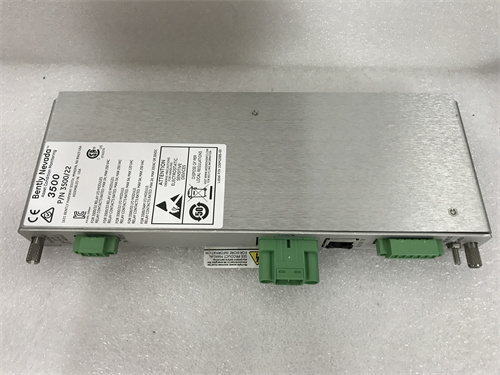

Bently Nevada 330180-X1-00 145004-95 3300 XL 8mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330180-X1-00 145004-95

Product Type:3300 XL 8mm Proximitor Sensor

Origin:USA

Dimensions:81.3 x 35.1 x 63.5 mm

Weight:0.246 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330180-X1-00 145004-95 3300 XL 8mm Proximitor Sensor is an advanced displacement sensor designed for precision monitoring of shaft position and vibration in rotating machinery. Part of the established 3300 XL series, this sensor features an 8mm sensing range suitable for close clearance applications in turbines, compressors, pumps, and other critical industrial equipment. Engineered for robustness and accuracy, it delivers reliable, stable data in demanding environments. The sensor plays a vital role in machinery protection and condition monitoring systems, providing essential information to prevent mechanical failures and optimize maintenance strategies.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330180-X1-00 145004-95 |

| Series | 3300 XL Proximitor Sensor Series |

| Sensing Range | 8 mm (±4 mm from centerline) |

| Output Type | AC displacement voltage output |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -50°C to +130°C |

| Frequency Response | 0.5 Hz to 10 kHz |

| Excitation Voltage | Nominal 6 Vrms, minimum 3.5 Vrms |

| Mounting Style | Threaded stud or flange mounting |

| Dimensions | 81.3 x 35.1 x 63.5 mm |

| Weight | 0.246 kg |

| Enclosure Rating | IP67, dust-tight and water-resistant |

| Connection Type | Shielded two-conductor cable |

Applications

This 3300 XL 8mm Proximitor Sensor finds application in:

Turbomachinery Monitoring: Measures shaft displacement and vibration in steam and gas turbines for enhanced operational safety.

Compressors and Pumps: Provides critical shaft position data for early fault detection.

Rotating Equipment Protection: Detects abnormal shaft movements to avoid mechanical damage.

Predictive Maintenance: Supports data-driven maintenance approaches by supplying accurate shaft condition data.

Power Generation Plants: Continuous monitoring of essential rotating machinery.

Heavy Industrial Equipment: Enables real-time monitoring to optimize machinery performance and longevity.

Product Advantages

High-Precision Measurement: Detects fine shaft movements with an 8mm sensing range for accurate condition monitoring.

Robust and Durable: Engineered to function reliably in harsh industrial environments with temperature extremes and vibration.

Wide Frequency Response: Sensitive across a broad frequency band from 0.5 Hz to 10 kHz.

Versatile Mounting Options: Supports both threaded stud and flange mounting for installation flexibility.

Consistent Output Signal: Provides a reliable AC displacement voltage signal.

System Compatibility: Easily integrates with Bently Nevada 3300 XL systems and compatible monitoring platforms.

Energy Efficient: Low power consumption for sustainable operation.

Electromagnetic Interference Protection: Shielded design minimizes EMI impact, ensuring signal integrity.

Proven Industrial Reliability: Widely trusted for critical machinery monitoring worldwide.

Low Maintenance: Factory calibrated with long-term stability reducing recalibration needs.

Frequently Asked Questions (FAQ)

What measurement principle does the 3300 XL Proximitor sensor use?

It employs eddy current displacement technology for accurate shaft position measurement.

Is the sensor designed to withstand high vibration environments?

Yes, it is specifically designed to maintain accuracy under significant vibration and shock.

What excitation voltage does the sensor require?

The sensor operates with an AC excitation voltage nominally 6 Vrms, minimum 3.5 Vrms.

What mounting options are supported?

Threaded stud and flange mounting methods are available.

How does temperature influence the sensor’s accuracy?

The sensor operates accurately within a temperature range of -40°C to +120°C.

What output signal type does the sensor provide?

It produces an AC displacement voltage proportional to shaft movement.

Can this sensor be used with monitoring systems other than Bently Nevada?

While optimized for Bently Nevada 3300 XL systems, its standard output enables integration with other compatible systems.

What materials are used for the sensor’s tip and housing?

The sensor tip is made from durable non-magnetic stainless steel; the housing is ruggedized for industrial applications.

Is frequent calibration necessary for this sensor?

Factory calibration ensures long-term stability and minimizes the need for frequent recalibration.

How is electromagnetic interference managed?

The sensor includes shielding and filtering to minimize EMI and maintain signal clarity.

Bently Nevada 330180-X1-00 145004-95 3300 XL 8mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330180-X1-00 145004-95

Product Type:3300 XL 8mm Proximitor Sensor

Origin:USA

Dimensions:81.3 x 35.1 x 63.5 mm

Weight:0.246 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330180-X1-00 145004-95 3300 XL 8mm Proximitor Sensor is an advanced displacement sensor designed for precision monitoring of shaft position and vibration in rotating machinery. Part of the established 3300 XL series, this sensor features an 8mm sensing range suitable for close clearance applications in turbines, compressors, pumps, and other critical industrial equipment. Engineered for robustness and accuracy, it delivers reliable, stable data in demanding environments. The sensor plays a vital role in machinery protection and condition monitoring systems, providing essential information to prevent mechanical failures and optimize maintenance strategies.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330180-X1-00 145004-95 |

| Series | 3300 XL Proximitor Sensor Series |

| Sensing Range | 8 mm (±4 mm from centerline) |

| Output Type | AC displacement voltage output |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -50°C to +130°C |

| Frequency Response | 0.5 Hz to 10 kHz |

| Excitation Voltage | Nominal 6 Vrms, minimum 3.5 Vrms |

| Mounting Style | Threaded stud or flange mounting |

| Dimensions | 81.3 x 35.1 x 63.5 mm |

| Weight | 0.246 kg |

| Enclosure Rating | IP67, dust-tight and water-resistant |

| Connection Type | Shielded two-conductor cable |

Applications

This 3300 XL 8mm Proximitor Sensor finds application in:

Turbomachinery Monitoring: Measures shaft displacement and vibration in steam and gas turbines for enhanced operational safety.

Compressors and Pumps: Provides critical shaft position data for early fault detection.

Rotating Equipment Protection: Detects abnormal shaft movements to avoid mechanical damage.

Predictive Maintenance: Supports data-driven maintenance approaches by supplying accurate shaft condition data.

Power Generation Plants: Continuous monitoring of essential rotating machinery.

Heavy Industrial Equipment: Enables real-time monitoring to optimize machinery performance and longevity.

Product Advantages

High-Precision Measurement: Detects fine shaft movements with an 8mm sensing range for accurate condition monitoring.

Robust and Durable: Engineered to function reliably in harsh industrial environments with temperature extremes and vibration.

Wide Frequency Response: Sensitive across a broad frequency band from 0.5 Hz to 10 kHz.

Versatile Mounting Options: Supports both threaded stud and flange mounting for installation flexibility.

Consistent Output Signal: Provides a reliable AC displacement voltage signal.

System Compatibility: Easily integrates with Bently Nevada 3300 XL systems and compatible monitoring platforms.

Energy Efficient: Low power consumption for sustainable operation.

Electromagnetic Interference Protection: Shielded design minimizes EMI impact, ensuring signal integrity.

Proven Industrial Reliability: Widely trusted for critical machinery monitoring worldwide.

Low Maintenance: Factory calibrated with long-term stability reducing recalibration needs.

Frequently Asked Questions (FAQ)

What measurement principle does the 3300 XL Proximitor sensor use?

It employs eddy current displacement technology for accurate shaft position measurement.

Is the sensor designed to withstand high vibration environments?

Yes, it is specifically designed to maintain accuracy under significant vibration and shock.

What excitation voltage does the sensor require?

The sensor operates with an AC excitation voltage nominally 6 Vrms, minimum 3.5 Vrms.

What mounting options are supported?

Threaded stud and flange mounting methods are available.

How does temperature influence the sensor’s accuracy?

The sensor operates accurately within a temperature range of -40°C to +120°C.

What output signal type does the sensor provide?

It produces an AC displacement voltage proportional to shaft movement.

Can this sensor be used with monitoring systems other than Bently Nevada?

While optimized for Bently Nevada 3300 XL systems, its standard output enables integration with other compatible systems.

What materials are used for the sensor’s tip and housing?

The sensor tip is made from durable non-magnetic stainless steel; the housing is ruggedized for industrial applications.

Is frequent calibration necessary for this sensor?

Factory calibration ensures long-term stability and minimizes the need for frequent recalibration.

How is electromagnetic interference managed?

The sensor includes shielding and filtering to minimize EMI and maintain signal clarity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...