Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

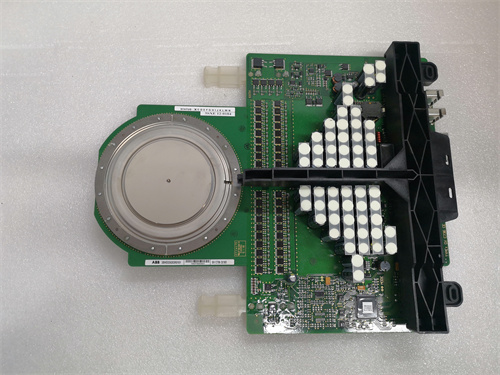

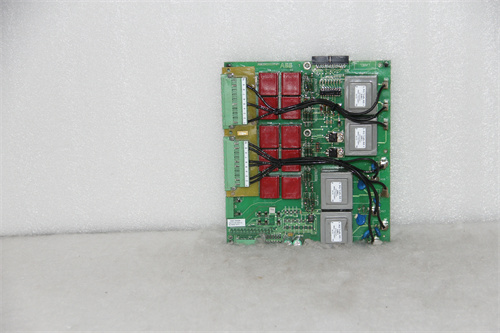

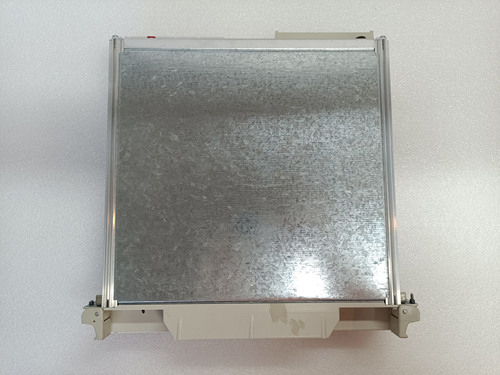

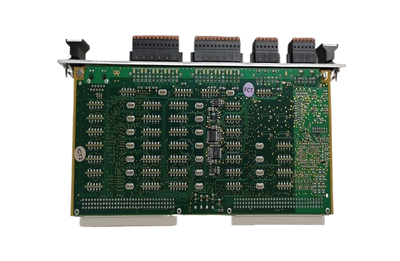

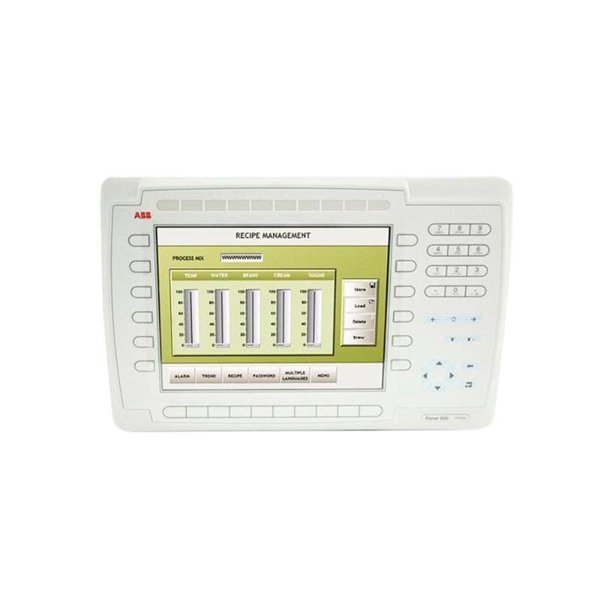

ABB PP846 3BSE042238R1 Operator Panel

Manufacturer:ABB

Product Number:PP846 3BSE042238R1

Product Type:Operator Panel

Origin:Sweden

Dimensions:290 × 230 × 55 mm

Weight:2.3 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PP846 3BSE042238R1 is an advanced operator panel engineered for high-reliability Human-Machine Interface (HMI) applications within the ABB 800xA distributed control system. Designed for enhanced operability and robust integration, the PP846 serves as a critical link between plant operators and automation processes.

This model is equipped with a large-format, high-resolution touchscreen display, industrial-grade computing capability, and a range of modern connectivity options. It offers intuitive process interaction, data visualization, and alarm handling while meeting the strict environmental and durability demands of sectors such as oil & gas, power generation, manufacturing, and utilities.

The PP846 is especially valued for its seamless interoperability with ABB’s AC 800M controllers and full compliance with ABB’s Extended Automation System 800xA platform, ensuring reliability and ease of use for control room operators and engineers alike.

Product Specifications

| Parameter | Details |

|---|---|

| Model | PP846 |

| Part Number | 3BSE042238R1 |

| Manufacturer | ABB |

| Product Type | Operator Panel (HMI) |

| Display Type | TFT LCD Touchscreen |

| Display Size | 15 inches (diagonal) |

| Touch Technology | Resistive single-touch |

| Processor | Embedded industrial-grade CPU (ARM or Intel architecture) |

| RAM | 1 GB |

| Flash Storage | 2 GB |

| Operating System | Embedded Linux / ABB Industrial OS |

| Ethernet Interface | 1 × RJ45 (10/100/1000 Mbps) |

| Serial Ports | 1 × RS-232, 1 × RS-485 |

| USB Ports | 2 × USB 2.0 |

| Power Supply | 24V DC (18–32V DC tolerance) |

| Power Consumption | < 25W |

| Mounting Type | Panel mounting |

| Protection Class | IP65 (front), IP20 (rear) |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5–95% non-condensing |

| Dimensions (W × H × D) | 290 × 230 × 55 mm |

| Weight | 2.3 kg |

| Compliance | CE, UL, cULus, RoHS |

| Software Compatibility | ABB 800xA, Control Builder, SoftControl, Industrial IT tools |

Product Applications

The ABB PP846 is used in a wide range of industrial and automation environments. Typical application scenarios include:

Power Generation Facilities: Turbine, generator, and substation HMI operations.

Oil & Gas Plants: Onshore and offshore systems for process visualization, alarm reporting, and control.

Water and Wastewater Treatment: Operator terminals for pump control, filtration monitoring, and chemical dosing.

Chemical Manufacturing: Safe process monitoring in hazardous environments.

Food & Beverage: Centralized control panel for temperature, packaging, and production line automation.

Automotive & Machine Building: Line control and diagnostics in assembly operations.

Product Advantages

Robust and Reliable: Built to handle the demands of harsh environments with IP65 front protection.

High-Resolution Display: 15-inch XGA screen provides detailed process graphics and real-time visualization.

Easy System Integration: Compatible with ABB’s control infrastructure including AC 800M and 800xA systems.

Low Maintenance: Fanless design reduces mechanical failure risks and increases MTBF.

Versatile Connectivity: Offers Ethernet, serial, and USB connections for interfacing with a wide array of devices.

Extended Product Lifecycle: Supported by ABB’s long-term product lifecycle strategy and global service network.

User-Centric Design: Ergonomic touchscreen layout facilitates rapid operator training and efficiency.

Frequently Asked Questions (FAQ)

Q: What control systems does the PP846 support?

A: The PP846 is fully compatible with ABB’s 800xA and AC 800M systems.

Q: Can the PP846 be used in outdoor applications?

A: It is primarily designed for indoor or cabinet installations. For outdoor use, additional enclosure is recommended.

Q: Is the software license included with the unit?

A: Licensing depends on the procurement agreement. Contact ABB or your distributor for specifics.

Q: Does the unit support multi-touch?

A: No, the PP846 uses resistive single-touch technology.

Q: What is the expected lifespan of this operator panel?

A: Under normal industrial conditions, it can last over 7–10 years.

Q: Is remote access possible through the PP846?

A: Yes, remote monitoring and configuration are supported via Ethernet.

Q: How is firmware updated on the PP846?

A: Firmware can be updated via USB or network depending on system configuration.

Q: What mounting options are supported?

A: The PP846 is designed for secure panel mounting with standard cutouts.

Q: Can I connect third-party PLCs to this panel?

A: Primarily designed for ABB systems, though integration via standard protocols (e.g., Modbus, Profibus) is possible.

Q: What certifications does the panel carry?

A: CE, UL, cULus, and RoHS compliance are standard.

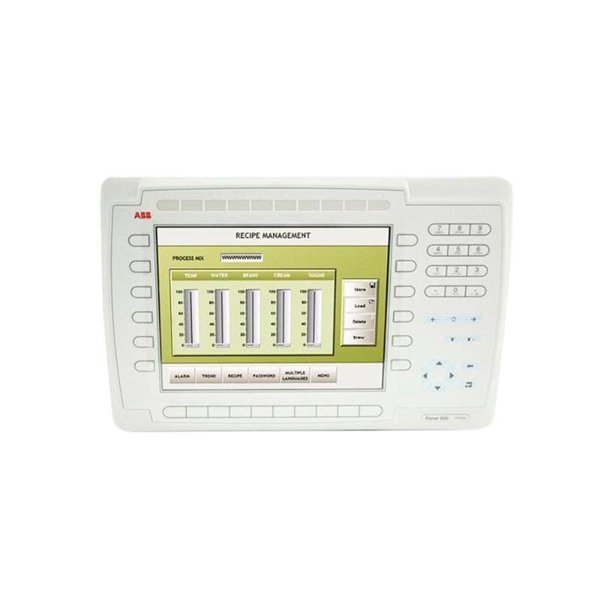

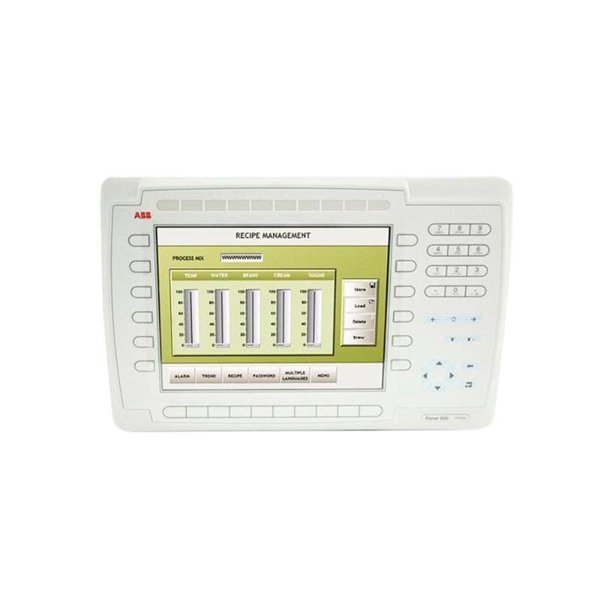

ABB PP846 3BSE042238R1 Operator Panel

Manufacturer:ABB

Product Number:PP846 3BSE042238R1

Product Type:Operator Panel

Origin:Sweden

Dimensions:290 × 230 × 55 mm

Weight:2.3 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PP846 3BSE042238R1 is an advanced operator panel engineered for high-reliability Human-Machine Interface (HMI) applications within the ABB 800xA distributed control system. Designed for enhanced operability and robust integration, the PP846 serves as a critical link between plant operators and automation processes.

This model is equipped with a large-format, high-resolution touchscreen display, industrial-grade computing capability, and a range of modern connectivity options. It offers intuitive process interaction, data visualization, and alarm handling while meeting the strict environmental and durability demands of sectors such as oil & gas, power generation, manufacturing, and utilities.

The PP846 is especially valued for its seamless interoperability with ABB’s AC 800M controllers and full compliance with ABB’s Extended Automation System 800xA platform, ensuring reliability and ease of use for control room operators and engineers alike.

Product Specifications

| Parameter | Details |

|---|---|

| Model | PP846 |

| Part Number | 3BSE042238R1 |

| Manufacturer | ABB |

| Product Type | Operator Panel (HMI) |

| Display Type | TFT LCD Touchscreen |

| Display Size | 15 inches (diagonal) |

| Touch Technology | Resistive single-touch |

| Processor | Embedded industrial-grade CPU (ARM or Intel architecture) |

| RAM | 1 GB |

| Flash Storage | 2 GB |

| Operating System | Embedded Linux / ABB Industrial OS |

| Ethernet Interface | 1 × RJ45 (10/100/1000 Mbps) |

| Serial Ports | 1 × RS-232, 1 × RS-485 |

| USB Ports | 2 × USB 2.0 |

| Power Supply | 24V DC (18–32V DC tolerance) |

| Power Consumption | < 25W |

| Mounting Type | Panel mounting |

| Protection Class | IP65 (front), IP20 (rear) |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5–95% non-condensing |

| Dimensions (W × H × D) | 290 × 230 × 55 mm |

| Weight | 2.3 kg |

| Compliance | CE, UL, cULus, RoHS |

| Software Compatibility | ABB 800xA, Control Builder, SoftControl, Industrial IT tools |

Product Applications

The ABB PP846 is used in a wide range of industrial and automation environments. Typical application scenarios include:

Power Generation Facilities: Turbine, generator, and substation HMI operations.

Oil & Gas Plants: Onshore and offshore systems for process visualization, alarm reporting, and control.

Water and Wastewater Treatment: Operator terminals for pump control, filtration monitoring, and chemical dosing.

Chemical Manufacturing: Safe process monitoring in hazardous environments.

Food & Beverage: Centralized control panel for temperature, packaging, and production line automation.

Automotive & Machine Building: Line control and diagnostics in assembly operations.

Product Advantages

Robust and Reliable: Built to handle the demands of harsh environments with IP65 front protection.

High-Resolution Display: 15-inch XGA screen provides detailed process graphics and real-time visualization.

Easy System Integration: Compatible with ABB’s control infrastructure including AC 800M and 800xA systems.

Low Maintenance: Fanless design reduces mechanical failure risks and increases MTBF.

Versatile Connectivity: Offers Ethernet, serial, and USB connections for interfacing with a wide array of devices.

Extended Product Lifecycle: Supported by ABB’s long-term product lifecycle strategy and global service network.

User-Centric Design: Ergonomic touchscreen layout facilitates rapid operator training and efficiency.

Frequently Asked Questions (FAQ)

Q: What control systems does the PP846 support?

A: The PP846 is fully compatible with ABB’s 800xA and AC 800M systems.

Q: Can the PP846 be used in outdoor applications?

A: It is primarily designed for indoor or cabinet installations. For outdoor use, additional enclosure is recommended.

Q: Is the software license included with the unit?

A: Licensing depends on the procurement agreement. Contact ABB or your distributor for specifics.

Q: Does the unit support multi-touch?

A: No, the PP846 uses resistive single-touch technology.

Q: What is the expected lifespan of this operator panel?

A: Under normal industrial conditions, it can last over 7–10 years.

Q: Is remote access possible through the PP846?

A: Yes, remote monitoring and configuration are supported via Ethernet.

Q: How is firmware updated on the PP846?

A: Firmware can be updated via USB or network depending on system configuration.

Q: What mounting options are supported?

A: The PP846 is designed for secure panel mounting with standard cutouts.

Q: Can I connect third-party PLCs to this panel?

A: Primarily designed for ABB systems, though integration via standard protocols (e.g., Modbus, Profibus) is possible.

Q: What certifications does the panel carry?

A: CE, UL, cULus, and RoHS compliance are standard.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...