Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

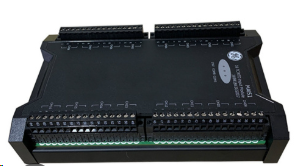

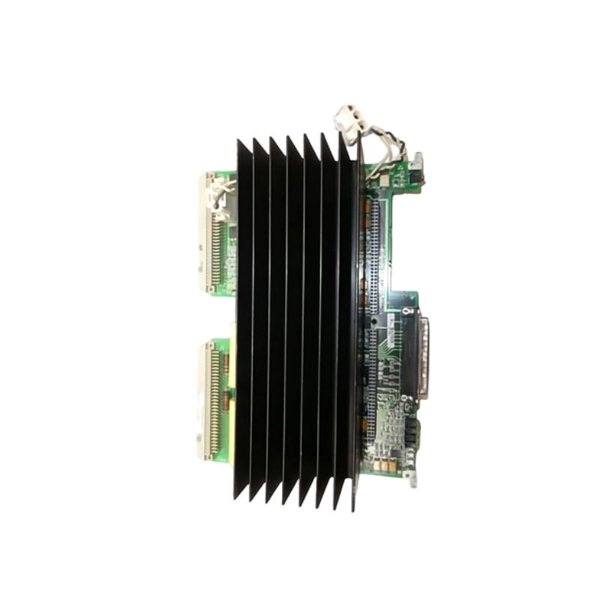

General Electric IS215REBFH1BA I/O Expansion Board

Manufacturer:GE

Product Number:IS215REBFH1BA

Product Type:I/O Expansion Board

Origin:USA

Dimensions:120 x 80 x 40 mm

Weight:0.45 kg

Views:48

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215REBFH1BA I/O Expansion Board is a high-reliability Relay Expansion Buffer Board used extensively in GE Mark VI and Mark VIe turbine control systems, part of GE’s renowned Speedtronic™ platform.

Specifically designed to expand relay signal capacity and maintain signal integrity between the controller and relay terminal blocks, the IS215REBFH1BA serves as an essential component in both primary and redundant I/O architectures. It ensures that critical control, trip, and alarm signals are accurately buffered, isolated, and delivered to field equipment, even in harsh industrial environments.

The board offers superior electrical isolation and buffering capabilities that protect downstream relay circuits from faults or electrical noise, making it ideal for use in gas turbines, steam turbines, power generation, and balance of plant (BoP) systems.

Built to rigorous GE industrial standards, the IS215REBFH1BA provides high reliability, extended service life, and is designed for continuous operation in demanding conditions such as those found in oil & gas, chemical, mining, and heavy manufacturing sectors.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215REBFH1BA I/O Expansion Board |

| Part Number | IS215REBFH1BA |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Relay Expansion Buffer Board (REB) |

| Function | Relay signal buffering and distribution |

| Number of Relay Paths Supported | 32 buffered relay outputs (typical) |

| Isolation | Channel-to-channel and system-to-relay |

| Input Signal Type | Logic-level relay drive signals |

| Output Drive Capacity | Nominal 28 VDC, max 1.5 A per channel |

| Diagnostics | Module-level diagnostics supported |

| Network Redundancy Support | Yes (for redundant system configurations) |

| Communication Interface | Direct wiring to relay terminal boards |

| PCB Coating | Industrial conformal coating |

| Power Supply | 28 VDC nominal |

| Power Consumption | < 5 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Shock Compliance | IEC 60068-2-27 |

| Vibration Compliance | IEC 60068-2-6 |

| Dimensions (H x W x D) | 120 x 80 x 40 mm |

| Weight | 0.45 kg |

| Mounting Method | Rack-mount in GE Mark VI / VIe system chassis |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

Expansion of relay output capacity in Mark VIe and Mark VI turbine control systems

-

Buffering relay drive signals in gas turbine applications

Steam turbine protection and trip relay control

-

Alarm signal isolation and distribution in generator protection systems

-

Enhanced redundant control architectures in power plants

-

Balance of Plant (BoP) control signal management

-

Relay interfacing for oil & gas processing plants

Petrochemical facility safety systems

-

Mining and materials processing equipment control

-

Industrial process automation systems for chemical and pharmaceutical sectors

Product Advantages

High relay channel density: Supports up to 32 relay outputs for large-scale I/O expansions

Electrical isolation: Channel-to-channel and system-to-relay isolation protects equipment

Optimized for Mark VI / VIe: Seamless system integration with GE Speedtronic™ controls

Diagnostic-ready: Enables rapid troubleshooting and maintenance

Low power operation: Efficient design with < 5 W typical power consumption

Industrial-grade construction: Tolerant of extreme temperatures, vibration, and EMI environments

Conformal-coated PCB: Added protection against moisture, dust, and corrosive agents

Redundant architecture ready: Suited for critical applications with dual-path redundancy

Long service life: Designed for 24/7 operation in mission-critical applications

Field-replaceable: Supports hot swap in rack-mounted configurations, minimizing downtime

Frequently Asked Questions (FAQ)

What is the main function of the IS215REBFH1BA?

It buffers and distributes relay control signals from GE Mark VI / VIe controllers to the relay terminal boards.

How many relay outputs does it support?

Typically, the board supports 32 relay outputs.

Is this board compatible with both Mark VI and Mark VIe?

Yes — the IS215REBFH1BA is fully compatible with both GE Mark VI and Mark VIe systems.

Does it provide signal isolation?

Yes — the board provides channel-to-channel and channel-to-system isolation.

Is this board suitable for redundant control configurations?

Yes — it is designed to work within redundant architecture environments.

What is the typical operating temperature range?

-30°C to +65°C (-22°F to +149°F).

Does the board support hot swap replacement?

Yes — it is a field-replaceable unit (FRU) in GE Mark VI/VIe rack systems.

What industries commonly use this board?

Industries include power generation, oil & gas, chemical processing, mining, and general process automation.

What kind of protection does the board have against environmental hazards?

The board is conformal-coated to withstand moisture, dust, and chemical exposure.

Is the board globally certified?

Yes — the board complies with CE, UL, CSA, and RoHS standards for international deployment.

General Electric IS215REBFH1BA I/O Expansion Board

Manufacturer:GE

Product Number:IS215REBFH1BA

Product Type:I/O Expansion Board

Origin:USA

Dimensions:120 x 80 x 40 mm

Weight:0.45 kg

Views:48

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215REBFH1BA I/O Expansion Board is a high-reliability Relay Expansion Buffer Board used extensively in GE Mark VI and Mark VIe turbine control systems, part of GE’s renowned Speedtronic™ platform.

Specifically designed to expand relay signal capacity and maintain signal integrity between the controller and relay terminal blocks, the IS215REBFH1BA serves as an essential component in both primary and redundant I/O architectures. It ensures that critical control, trip, and alarm signals are accurately buffered, isolated, and delivered to field equipment, even in harsh industrial environments.

The board offers superior electrical isolation and buffering capabilities that protect downstream relay circuits from faults or electrical noise, making it ideal for use in gas turbines, steam turbines, power generation, and balance of plant (BoP) systems.

Built to rigorous GE industrial standards, the IS215REBFH1BA provides high reliability, extended service life, and is designed for continuous operation in demanding conditions such as those found in oil & gas, chemical, mining, and heavy manufacturing sectors.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215REBFH1BA I/O Expansion Board |

| Part Number | IS215REBFH1BA |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Relay Expansion Buffer Board (REB) |

| Function | Relay signal buffering and distribution |

| Number of Relay Paths Supported | 32 buffered relay outputs (typical) |

| Isolation | Channel-to-channel and system-to-relay |

| Input Signal Type | Logic-level relay drive signals |

| Output Drive Capacity | Nominal 28 VDC, max 1.5 A per channel |

| Diagnostics | Module-level diagnostics supported |

| Network Redundancy Support | Yes (for redundant system configurations) |

| Communication Interface | Direct wiring to relay terminal boards |

| PCB Coating | Industrial conformal coating |

| Power Supply | 28 VDC nominal |

| Power Consumption | < 5 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Shock Compliance | IEC 60068-2-27 |

| Vibration Compliance | IEC 60068-2-6 |

| Dimensions (H x W x D) | 120 x 80 x 40 mm |

| Weight | 0.45 kg |

| Mounting Method | Rack-mount in GE Mark VI / VIe system chassis |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

Expansion of relay output capacity in Mark VIe and Mark VI turbine control systems

-

Buffering relay drive signals in gas turbine applications

Steam turbine protection and trip relay control

-

Alarm signal isolation and distribution in generator protection systems

-

Enhanced redundant control architectures in power plants

-

Balance of Plant (BoP) control signal management

-

Relay interfacing for oil & gas processing plants

Petrochemical facility safety systems

-

Mining and materials processing equipment control

-

Industrial process automation systems for chemical and pharmaceutical sectors

Product Advantages

High relay channel density: Supports up to 32 relay outputs for large-scale I/O expansions

Electrical isolation: Channel-to-channel and system-to-relay isolation protects equipment

Optimized for Mark VI / VIe: Seamless system integration with GE Speedtronic™ controls

Diagnostic-ready: Enables rapid troubleshooting and maintenance

Low power operation: Efficient design with < 5 W typical power consumption

Industrial-grade construction: Tolerant of extreme temperatures, vibration, and EMI environments

Conformal-coated PCB: Added protection against moisture, dust, and corrosive agents

Redundant architecture ready: Suited for critical applications with dual-path redundancy

Long service life: Designed for 24/7 operation in mission-critical applications

Field-replaceable: Supports hot swap in rack-mounted configurations, minimizing downtime

Frequently Asked Questions (FAQ)

What is the main function of the IS215REBFH1BA?

It buffers and distributes relay control signals from GE Mark VI / VIe controllers to the relay terminal boards.

How many relay outputs does it support?

Typically, the board supports 32 relay outputs.

Is this board compatible with both Mark VI and Mark VIe?

Yes — the IS215REBFH1BA is fully compatible with both GE Mark VI and Mark VIe systems.

Does it provide signal isolation?

Yes — the board provides channel-to-channel and channel-to-system isolation.

Is this board suitable for redundant control configurations?

Yes — it is designed to work within redundant architecture environments.

What is the typical operating temperature range?

-30°C to +65°C (-22°F to +149°F).

Does the board support hot swap replacement?

Yes — it is a field-replaceable unit (FRU) in GE Mark VI/VIe rack systems.

What industries commonly use this board?

Industries include power generation, oil & gas, chemical processing, mining, and general process automation.

What kind of protection does the board have against environmental hazards?

The board is conformal-coated to withstand moisture, dust, and chemical exposure.

Is the board globally certified?

Yes — the board complies with CE, UL, CSA, and RoHS standards for international deployment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...